Linear electromagnetic normally-closed valve of automobile braking system

A technology of automobile braking system and normally closed valve, which is applied in the direction of lifting valve, valve device, engine components, etc., can solve the problem that the precise control of the valve port cannot be realized, and achieve the effect of linear control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

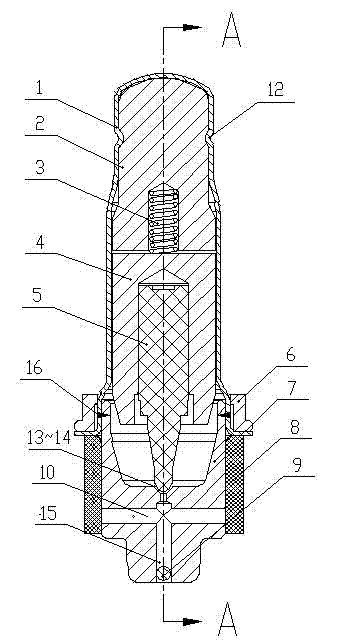

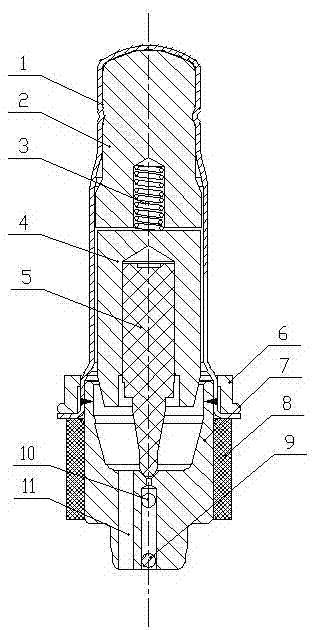

[0012] Such as figure 1 As shown, the linear electromagnetic normally closed valve includes magnetic isolation tube 1, fixed iron 2, spring 3, moving iron assembly (moving iron 4 and push rod 5), flange 6, valve seat 7, ring filter 8, steel ball 9 . The push rod 5 is pressed into the interior of the moving iron 4 through interference fit to form a moving iron assembly, which can move axially in the magnetic isolation tube 2 . The spring 3 is loaded inside the fixed iron 2, the fixed iron 2 is connected with the moving iron assembly through the spring 3, and the spring 3 has a certain pretightening force. The moving iron 2 is pressed into the magnetic isolation tube 2 through an interference fit, and fixed by a riveting method 12 to prevent the moving iron from moving up and down. The valve seat 6 and the magnetic isolation tube 2 are fixed by laser welding (). In the state of power failure, the spherical tip 13 of the push rod 5 and the conical surface 14 of the valve seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com