Ignition groove of natural gas rotary engine

A rotary engine and natural gas technology, applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of increased engine cost, easy loss of ignition energy, and prolonged combustion period, so as to increase the overall combustion speed and improve air leakage Phenomenon, the effect of ignition energy reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

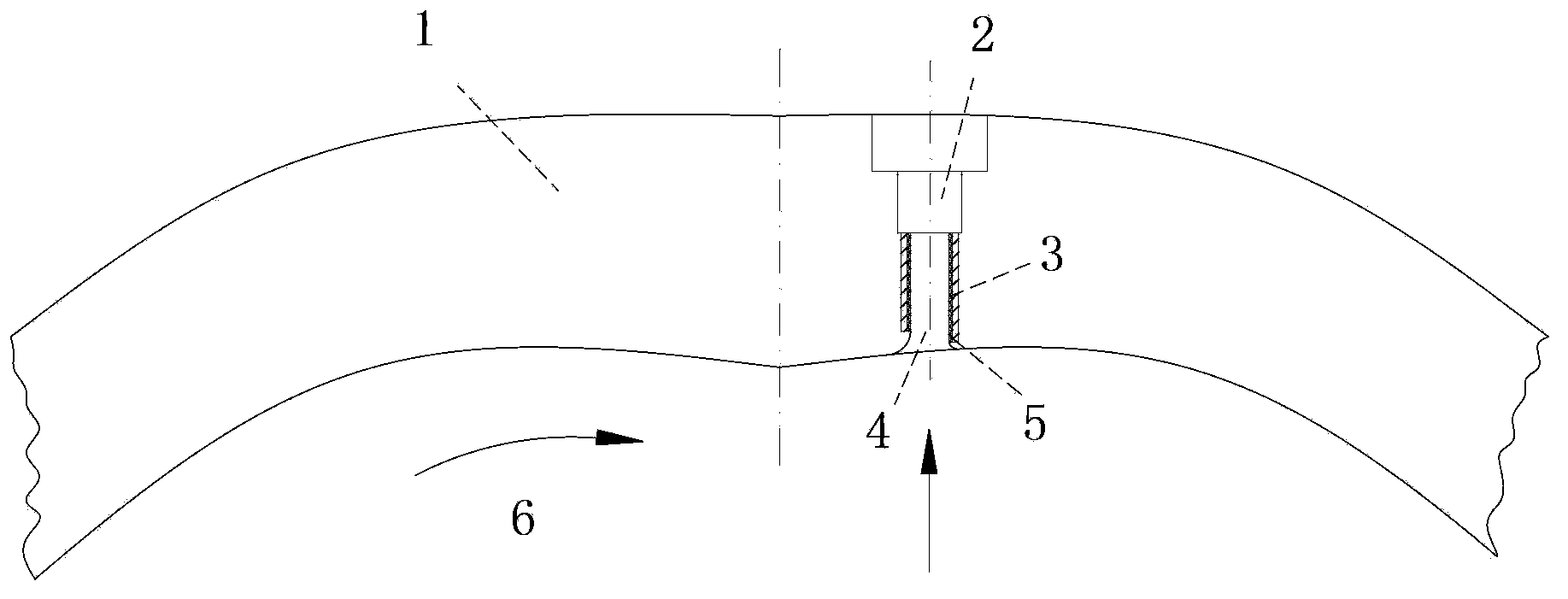

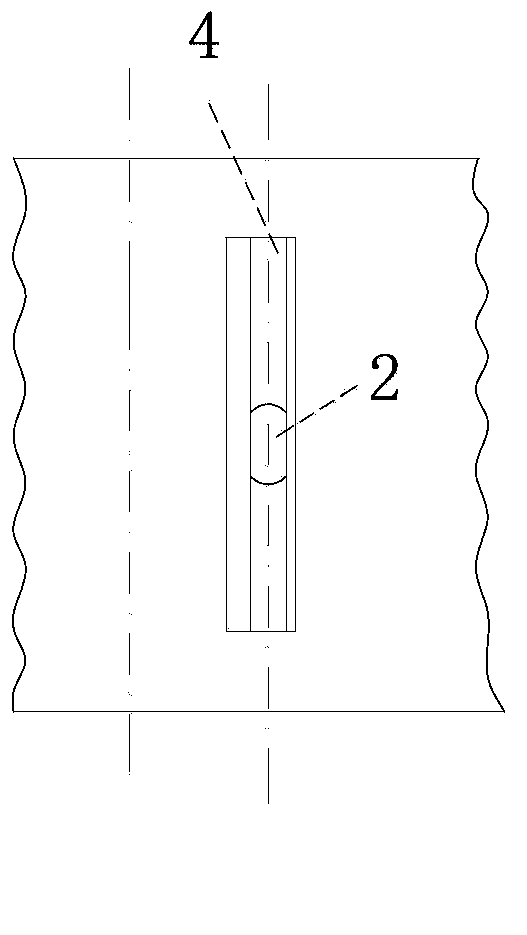

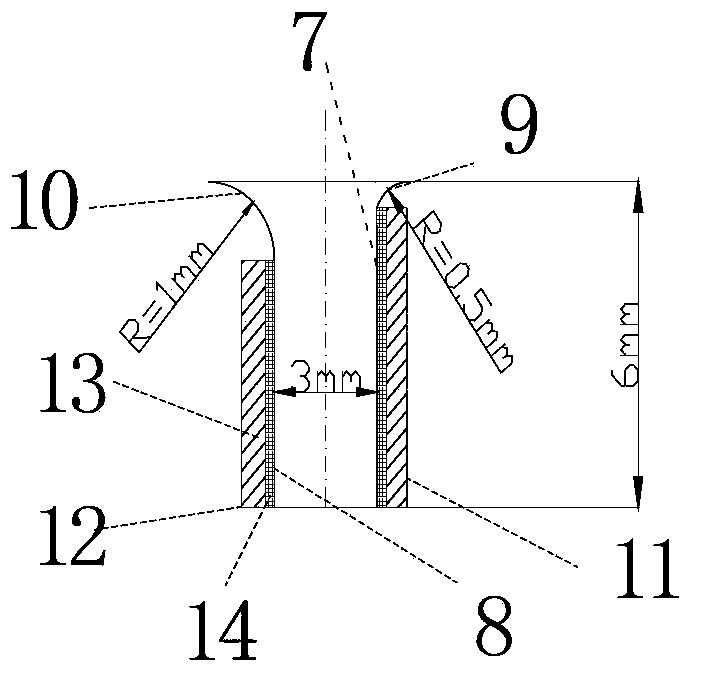

[0022] see figure 1 and 2 Open the spark plug installation hole 2 on the cylinder block 1, and install the spark plug on the bottom of the ignition groove. Since the ignition groove is designed to be suitable for generating a stable air swirl, the shape of the groove 4 must be well coupled with the direction of the airflow in the cylinder. 6 , so that the air flow enters the channel smoothly, that is, connect the front wall of the ignition tank with the cylinder profile with a small arc, and connect the rear wall with the cylinder profile with a large arc. The specific processing method is to cast with the cylinder body. When casting Rectangular pits are left on the front and rear walls to inlay silicon carbide sheets 3; in order to prevent air leakage during engine operation, the groove width is designed to be 3 mm. Propagating quenching phenomenon, inlaid silicon carbide sheet with platinum catalyst coating 5 on the wall surface of the ignition tank, under the catalytic act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com