Method for selectively separating lignin and cellulose from lignocellulose biomasses

A lignocellulosic and biomass technology, which is applied in the direction of raw material separation, non-woody plant/crop pulp, pulping with organic solvents, etc., can solve the problems of undiscovered industrial application fields, increase the effective specific surface area, reduce Production cost, effect of promoting degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for selectively separating lignin and cellulose from lignocellulosic biomass, comprising the following steps:

[0026] a. Pretreatment of lignocellulosic biomass: pulverize sesame straw, pass through a 180-mesh sieve, dry in an oven at 105°C for 60 minutes, and then expand to obtain sesame straw particles for subsequent use;

[0027] b. Dissolution of lignocellulose and degradation of biomass: Weigh 15g of ionic liquid 1-butyl-3-methylimidazolium chloride salt into a 50mL flask, heat and melt in an oil bath at 104°C, and stir the ions Liquid and add 2.5g of sesame straw granules to it, seal the flask, control the temperature at 90°C, keep stirring and heating for 2h to obtain a viscous substance;

[0028] Add 10% dilute hydrochloric acid dropwise to the viscous substance obtained above while stirring, adjust the pH value to 4.5, and continue heating and stirring for 5 hours to obtain a reaction slurry;

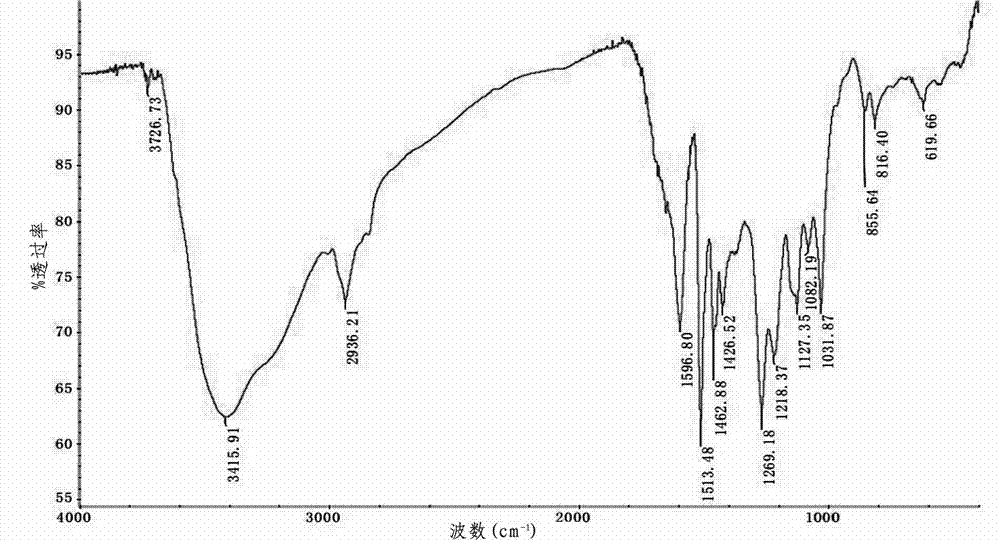

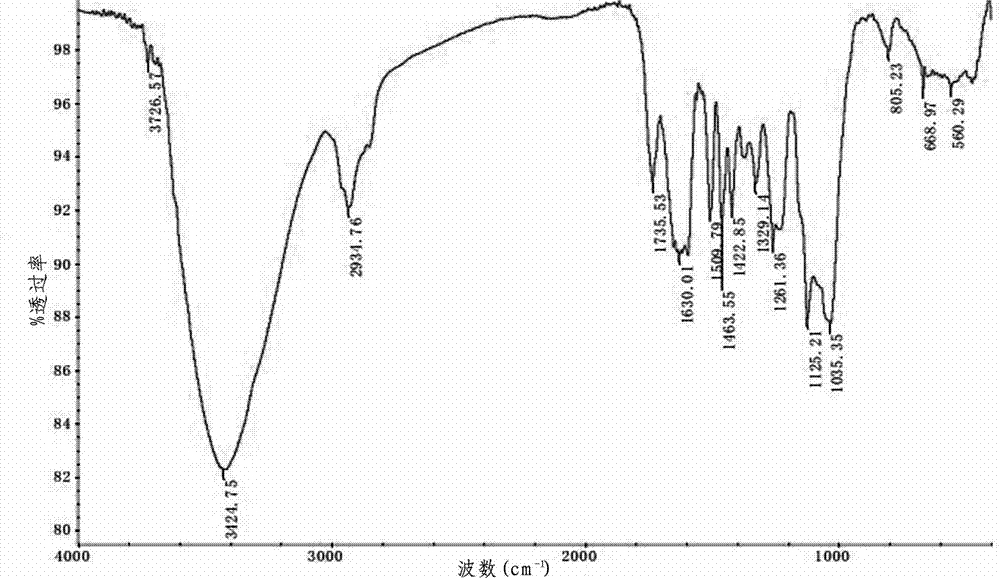

[0029] c. Extraction and separation: After cooling the r...

Embodiment 2

[0039] A method for selectively separating lignin and cellulose from lignocellulosic biomass, comprising the following steps:

[0040] a. Pretreatment of lignocellulosic biomass: crush corn stalks, pass through a 180-mesh sieve, dry in an oven at 80°C for 60 minutes, and then puff them to obtain corn stalk particles for later use;

[0041]b. Dissolution of lignocellulose and degradation of biomass: Weigh 15g of ionic liquid 1-butyl-3-methylimidazolium chloride salt in a 100mL flask, heat and melt in an oil bath at 95°C, and stir the ions Liquid and add 2.5g of corn stalk particles to it, seal the flask, control the temperature at 110°C, stir and heat continuously for 3h to obtain a viscous substance;

[0042] Add 5% dilute hydrochloric acid dropwise to the viscous substance obtained above while stirring, adjust the pH value to 4.8, continue heating and stirring for 7 hours, and obtain a reaction slurry;

[0043] c. Extraction and separation: After cooling the reaction slurry ...

Embodiment 3

[0046] A method for selectively separating lignin and cellulose from lignocellulosic biomass, comprising the following steps:

[0047] a. Pretreatment of lignocellulosic biomass: crush peanut shells, pass through a 180-mesh sieve, dry in an oven at 110°C for 90 minutes, and then expand to obtain peanut shell particles for subsequent use;

[0048] b. Dissolution of lignocellulose and degradation of biomass: Weigh 50g of ionic liquid 1-butyl-3-methylimidazolium chloride salt in a 500mL flask, heat and melt in an oil bath at 110°C, and stir the ions Add 20g of peanut shell particles to the liquid, seal the flask, control the temperature at 90°C, keep stirring and heating for 2.5h to obtain a viscous substance;

[0049] Add 8% dilute hydrochloric acid dropwise to the viscous substance obtained above while stirring, adjust the pH value to 4.5, and continue heating and stirring for 5 hours to obtain a reaction slurry;

[0050] d. Extraction and separation: after cooling the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com