Porous membrane mixed by 1,4-dihydroxy anthraquinone and cellulose, preparation method and usage

A technology of dihydroxyanthraquinone and porous membrane, applied in 1 field, to achieve good selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The concrete steps of preparation are:

[0032] Step 1, first mix cellulose acetate, 1,4-dihydroxyanthraquinone and solvent according to the ratio of 7.5wt% by weight: 0.1wt%: 92.4wt%; wherein, the solvent is a mixed solution of acetone and deionized water, A spinning solution is obtained. Then the spinning solution is placed on the electrospinning machine for 3min electrospinning, wherein the distance between the positive and negative electrodes during electrospinning is 10cm, the electrostatic voltage is 26kV, and the flow rate of the spinning solution is 0.001mL / s , the nanofibers were collected by a grounded aluminum plate, resulting in a porous membrane composed of cellulose acetate nanofibers doped with 1,4-dihydroxyanthraquinone.

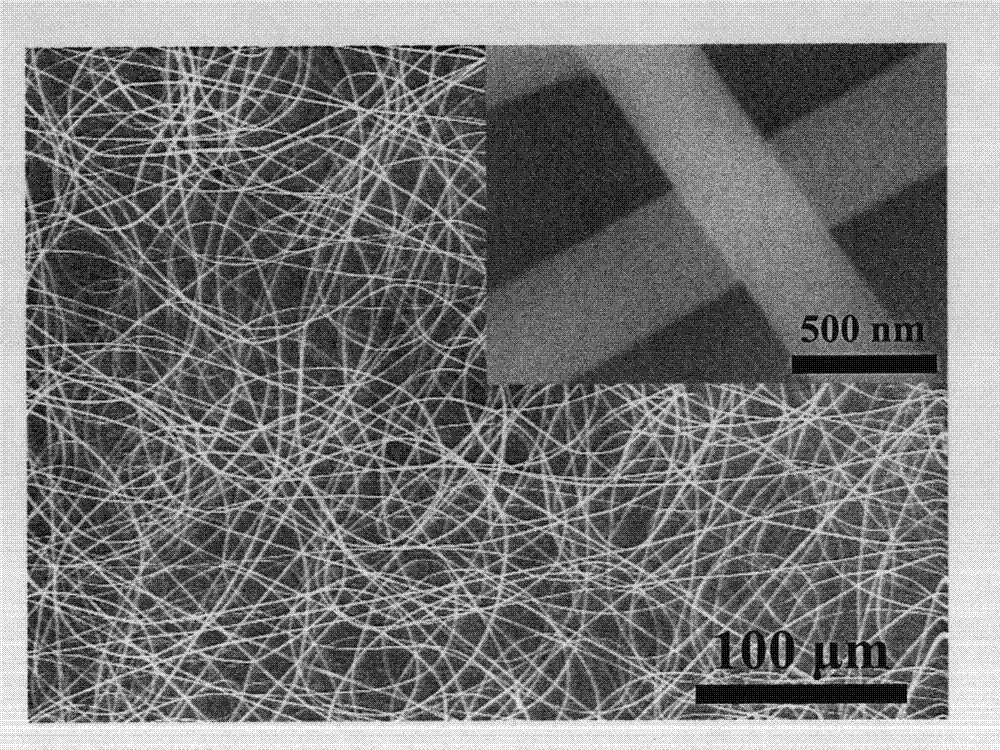

[0033] In step 2, the porous membrane composed of cellulose acetate nanofibers doped with 1,4-dihydroxyanthraquinone is soaked in sodium hydroxide solution for 24 hours to obtain a film similar to figure 1 Shown is a porous membrane ...

Embodiment 2

[0035] The concrete steps of preparation are:

[0036] Step 1, first mix cellulose acetate, 1,4-dihydroxyanthraquinone and solvent according to the ratio of 7.8wt% by weight: 0.1wt%: 92.1wt%; wherein, the solvent is a mixed solution of acetone and deionized water, A spinning solution is obtained. Then the spinning solution is placed on the electrospinning machine for 3.5 minutes of electrospinning, wherein the distance between the positive and negative electrodes during electrospinning is 10cm, the electrostatic voltage is 26kV, and the flow rate of the spinning solution is 0.001mL / s, Nanofibers were collected by a grounded aluminum plate to obtain a porous membrane composed of cellulose acetate nanofibers doped with 1,4-dihydroxyanthraquinone.

[0037] In step 2, the porous membrane composed of cellulose acetate nanofibers doped with 1,4-dihydroxyanthraquinone is soaked in sodium hydroxide solution for 25 hours to obtain a film similar to figure 1 Shown is a porous membrane ...

Embodiment 3

[0039] The concrete steps of preparation are:

[0040] Step 1, first cellulose acetate, 1,4-dihydroxyanthraquinone and solvent are mixed according to the ratio of 8wt% by weight: 0.1wt%: 91.9wt%; wherein, the solvent is a mixed solution of acetone and deionized water to obtain spinning solution. Then the spinning solution is placed on the electrospinning machine for 4min electrospinning, wherein the distance between the positive and negative electrodes during electrospinning is 10cm, the electrostatic voltage is 26kV, and the flow rate of the spinning solution is 0.001mL / s , the nanofibers were collected by a grounded aluminum plate, resulting in a porous membrane composed of cellulose acetate nanofibers doped with 1,4-dihydroxyanthraquinone.

[0041] In step 2, the porous membrane composed of cellulose acetate nanofibers doped with 1,4-dihydroxyanthraquinone is soaked in sodium hydroxide solution for 26 hours to obtain the following: figure 1 Shown is a porous membrane comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com