Polypyrrolone/sulfonated polymer composite proton exchange membrane material, and preparation method and application thereof

A sulfonated polymer, proton exchange membrane technology, applied in solid electrolyte fuel cells, fuel cell parts, electrical components, etc., can solve problems such as insoluble and infusible, achieve simple operation, good mechanical strength and electrical conductivity , the effect of uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

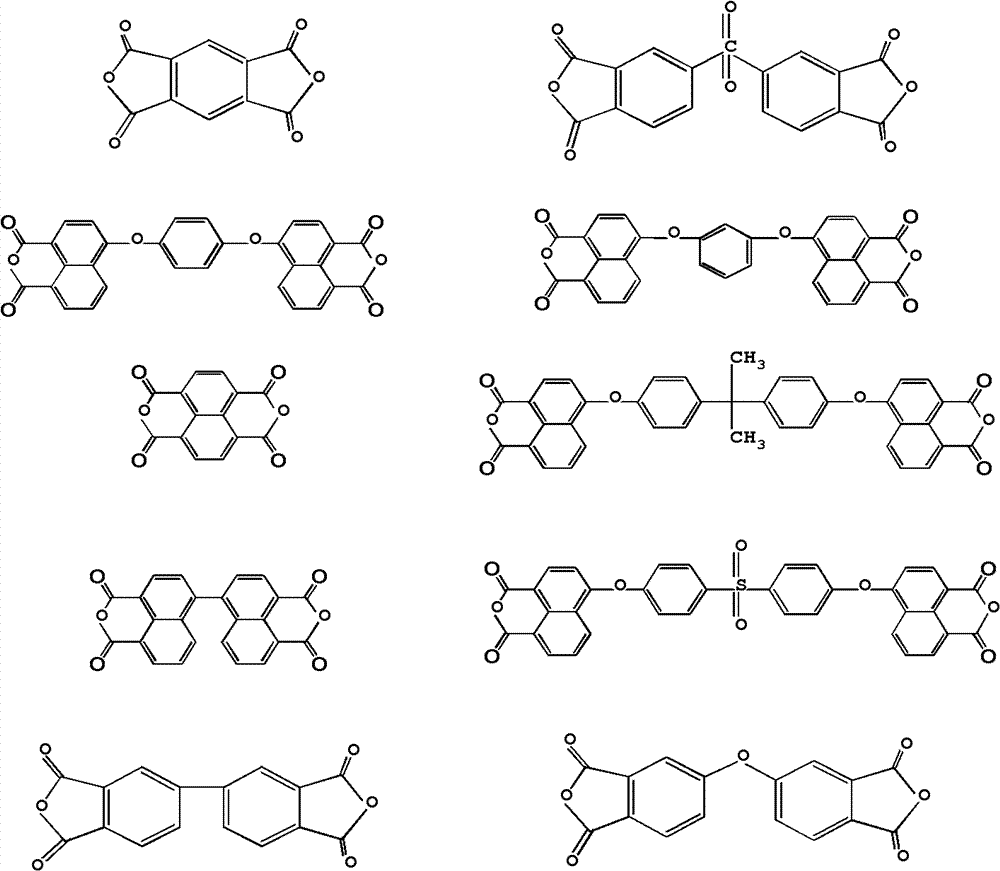

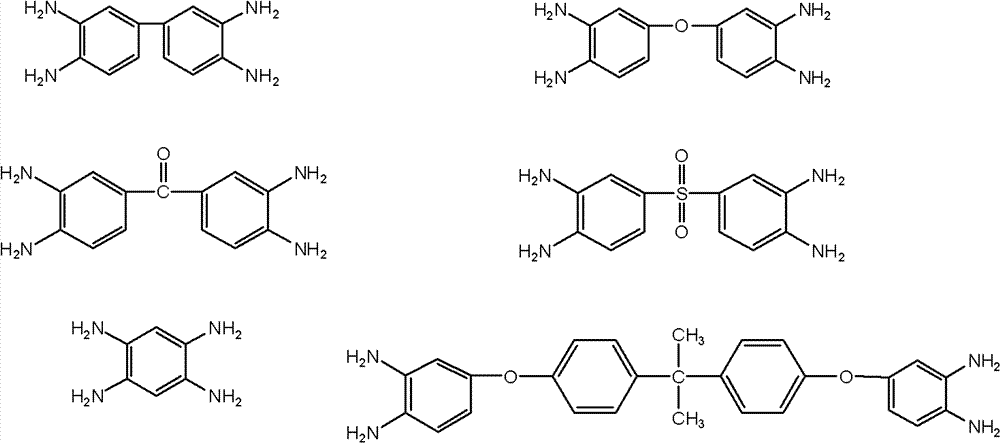

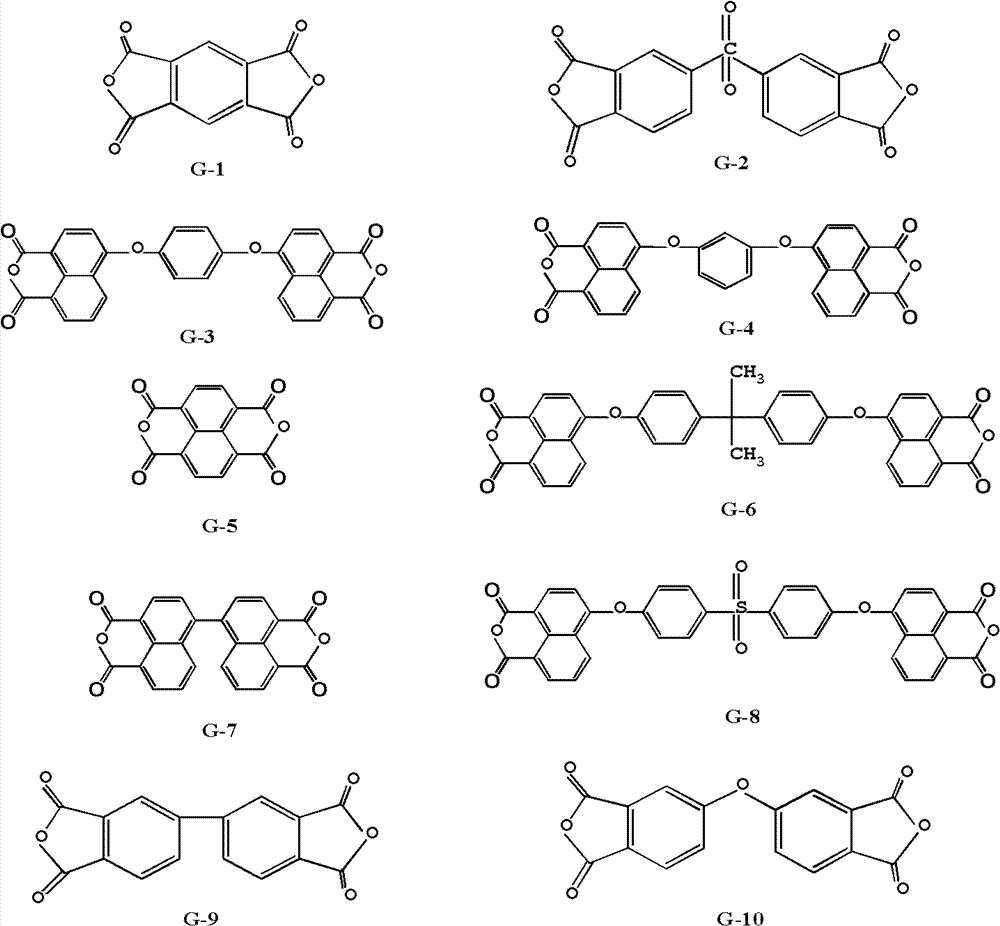

[0038] Example 1: Preparation of Polypyrrole / Sulfonated Polyetheretherketone Composite Proton Exchange Membrane

[0039] Soak sulfonated polyether ether ketone (number average molecular weight: 60,000) with a sulfonation degree of 95% in 1mol / L NaOH solution for 24 hours, wash with water until neutral and dry in vacuum, then dissolve in an appropriate amount of m-cresol , configured as a polymer solution with a mass percentage of 30%; weigh 2000g of the polymer solution and place it in a three-necked flask, add 2.78g of tetraamine monomer (A-1), 1.2g of trimethylamine (catalyst), and stir until The reactants were fully dissolved. Weigh 3.22 g of aromatic dianhydride monomer (G-1), and dissolve it in 10 mL of m-cresol. at -10°C and N 2 Under the protection of gas, the aromatic dianhydride solution was slowly added dropwise into the above-mentioned three-necked flask. After the drop, the reaction temperature was slowly raised to 0°C, and the stirring reaction was continued for...

Embodiment 2

[0042] Example 2: Preparation of polypyrrone / sulfonated polyethersulfone composite proton exchange membrane

[0043] Soak sulfonated polyethersulfone (number-average molecular weight: 40,000) with a sulfonation degree of 85% in 1mol / L NaOH solution for 24 hours, wash with water repeatedly, dry in vacuum, dissolve in dimethyl sulfoxide, and configure A polymer solution with a mass percentage of 5%; weigh 3000g of the polymer solution and place it in a three-neck bottle. in N 2 Under gas protection, 18.9 g of tetraamine monomer (A-2) and 0.6 g of trimethylamine (catalyst) were added, and stirring was started to fully dissolve the reactants. Weigh 41.1 g of the aromatic dianhydride monomer (G-3), and dissolve it in 500 mL of dimethyl sulfoxide. at 10°C and N 2 Under the protection of gas, the aromatic dianhydride solution was slowly added dropwise into the above-mentioned three-neck flask. After the drop was completed, the reaction temperature was kept at 10° C., and the stirrin...

Embodiment 3

[0046] Example 3: Preparation of polypyrrone / sulfonated polyether ether ketone sulfone composite proton exchange membrane

[0047] Sulfonated polyether ether ketone sulfone (number average molecular weight: 10000) with a sulfonation degree of 75% was mixed with 2mol / L NaHCO 3 The solution was soaked for 24 hours, washed with water until neutral and vacuum-dried, dissolved in an appropriate amount of dimethylformamide to prepare a solution with a mass percentage of 20%, and 1000g of the polymer solution was weighed and placed in a three-neck bottle. in N 2 Under gas protection, 9.49 g of tetraamine monomer (A-3) and 2 g of triphenylphosphine (catalyst) were added, and stirring was started to fully dissolve the reactants. Weigh 10.51 g of aromatic dianhydride monomer (G-5), and dissolve it in 100 mL of dimethyl sulfoxide. at 25°C and N 2 Under the protection of gas, the aromatic dianhydride solution was slowly added dropwise into the above-mentioned three-necked flask, and af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com