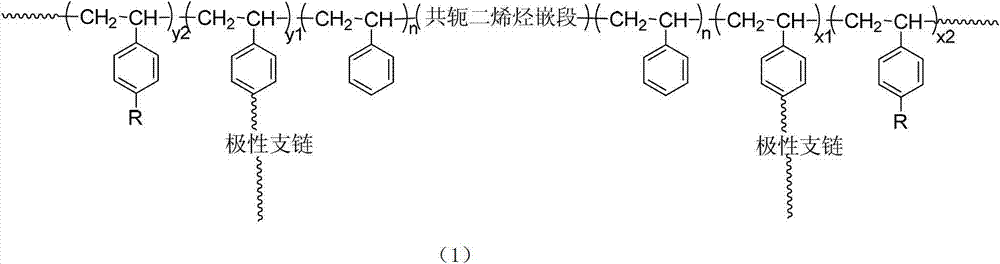

Thermoplastic elastomer containing polar styrene block and preparation method thereof

A thermoplastic elastomer, styrene block technology, applied in the field of pressure-sensitive adhesives, can solve the problems of increased polarity of thermoplastic elastomers, unsatisfactory bonding effect of polar materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

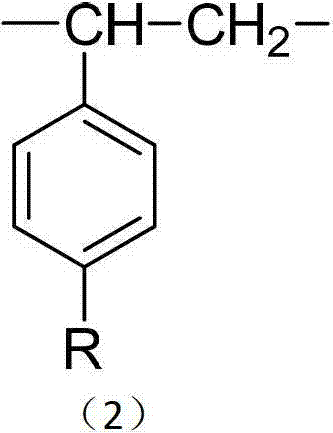

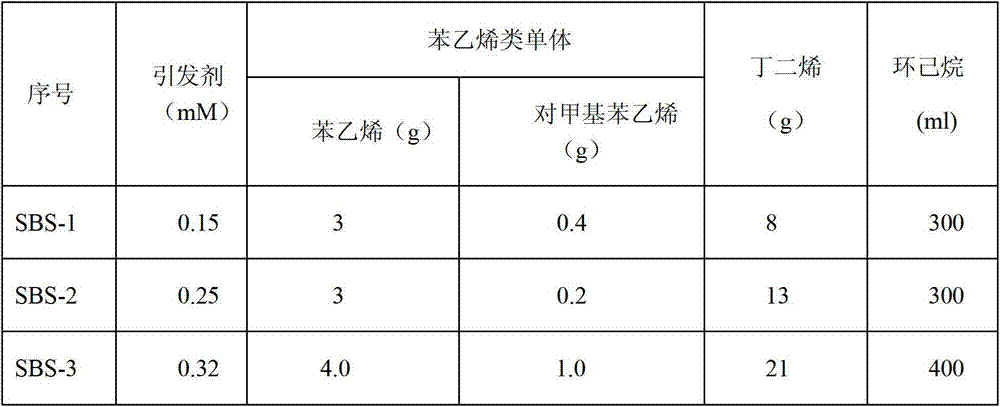

[0017] Embodiment 1 Contains the preparation of the SBS of p-methylstyrene

[0018] Add the measured solvent, the mixture of 4-methylstyrene / styrene in different ratios, and the activator THF into the polymerization bottle. After preheating at 40~50°C for half an hour, add n-butyllithium according to the molecular weight design Initiator, react for 3 hours, then add measured butadiene, control the reaction temperature at 80°C, continue to react for 1 hour, add coupling agent 1,2-dibromoethane, and maintain the temperature between 75~100°C After reacting for 1 hour, the reaction was stopped, and the obtained product was coagulated, washed and dried for later use. The experimental data are listed in Table 1, and the product structure test results are listed in Table 2. Table I

[0019]

[0020] Table II

[0021]

Embodiment 2

[0022] Example 2 Carry out lithiation and grafting reaction to SBS-1 obtained in Example 1

[0023] At 50°C, dissolve 2g of SBS-1 in a 100ml polymerization bottle with 50ml of toluene, and add 5ml of n-butyl lithium with a concentration of 1.4mol / L and 2ml of TMEDA to carry out lithiation reaction. After 2 hours of reaction, Add toluene to wash repeatedly until the pH of the washing liquid is neutral, introduce 30ml of toluene, add 1g of ethylene oxide monomer, carry out capping reaction, react at 40°C for 10 hours, and then add 0.6mmol of phosphorus at -50~-40°C Nitrile, carry out the grafting reaction of side chain ethylene oxide, react at 40 ℃ for 3 days. All the reactions were performed under the protection of argon to obtain a thermoplastic elastomer polymer with polyethylene oxide as the branched chain and SBS as the main chain. The product structure test results are shown in Table 3.

Embodiment 3

[0024] Example 3 Carry out lithiation and grafting reaction to the SBS-2 obtained in Example 1

[0025] At 50°C, dissolve 2g of SBS-2 in a 100ml polymerization bottle with 50ml of tetrahydrofuran, and add 5ml of n-butyllithium with a concentration of 1.4mol / L and 1ml of TMEDA to carry out lithiation reaction. After 3 hours of reaction, Add tetrahydrofuran to wash repeatedly until the pH of the washing liquid is neutral, introduce 30ml tetrahydrofuran, add 1.5g ethylene oxide monomer, and carry out capping reaction. The reaction time is 10 hours at 40°C, and then add 0.2 mmol phosphazene, carry out the grafting reaction of side chain oxirane, react at 50 ℃ for 3 days. All the reactions were performed under the protection of argon to obtain a thermoplastic elastomer polymer with polyethylene oxide as the branched chain and SBS as the main chain. The product structure test results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com