Methyl naphthol wastewater treatment process

A technology for wastewater treatment and methylnaphthol, which is applied in the field of water treatment, can solve the problems of high cost, poor effect of methylnaphthol wastewater, and high cost, so as to reduce investment and operation costs, save biochemical treatment process, and simplify process The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

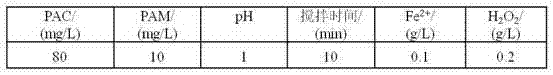

[0012] The conditions for processing each component of methyl naphthol wastewater are as follows:

[0013]

[0014] Use sodium hydroxide or sulfuric acid to adjust the pH of the wastewater to 1, add PAC coagulant at a concentration of 80 mg / L, and when small flocs appear, add PAM coagulant with a concentration of 10 mg / L, and stir The speed is 60r / min, after stirring for 10min, let it settle for 20min, then filter, and then add the concentration of 0.1 g / LFe 2+ and 0.2 g / LH 2 o 2 Carry out deep oxidation treatment, the oxidation time is 120min. Analysis after treatment showed that the COD removal rate of methyl naphthol wastewater was 35.8%.

Embodiment 2

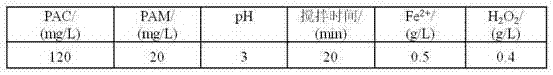

[0016] The conditions for processing each component of methyl naphthol wastewater are as follows:

[0017]

[0018] Use sodium hydroxide or sulfuric acid to adjust the pH of the wastewater to 3, add PAC coagulant at a concentration of 120 mg / L, and when small flocs appear, add PAM coagulant with a concentration of 20 mg / L, and stir The speed is 60r / min, after stirring for 20min, let it settle for 20min, then filter, and then add the concentration of 0.5 g / LFe 2+ and 0.4 g / LH 2 o 2 Carry out deep oxidation treatment, the oxidation time is 120min. Analysis after treatment showed that the COD removal rate of methyl naphthol wastewater was 65.3%.

Embodiment 3

[0020] The conditions for processing each component of methyl naphthol wastewater are as follows:

[0021]

[0022] Use sodium hydroxide or sulfuric acid to adjust the pH of the wastewater to 5, add PAC coagulant at a concentration of 140 mg / L, and when small flocs appear, add PAM coagulant with a concentration of 20 mg / L, and stir The speed is 60r / min, after stirring for 30min, let it settle for 20min, then filter, and then add the concentration of 1.0 g / LFe 2+ and 0.8 g / LH 2 o 2 Carry out deep oxidation treatment, the oxidation time is 120min. Analysis after treatment showed that the COD removal rate of methyl naphthol wastewater was 92.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com