Nanometer gallium oxide and application thereof

A gallium oxide, nanotechnology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as the need to improve catalytic activity, limit the application of catalysts, reduce the activity and life of catalysts, and achieve rapid Effective degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1: Synthesis of Fan-shaped Nanostructure Gallium Oxide by Hydrothermal Method

[0051] The preparation of fan-shaped nano gallium oxide: according to gallium nitrate hydrate (Ga(NO 3 ) 3 wxya 2 O), polyvinyl alcohol (PVA) and water in a mass ratio of 20:1:200 are mixed to form a solution. Without adjusting the pH, the solution was heated in a water bath at 90°C for 10 minutes. Then transfer the obtained product to a sealed polytetrafluoroethylene hydrothermal kettle, place it in a constant temperature drying oven, heat it at 200°C for a period of time, take out the hydrothermal kettle, cool it to room temperature, and centrifuge the product in the kettle. The washed and dried powder is placed in a tube furnace, calcined at 700° C. for a period of time under nitrogen atmosphere, and finally the obtained product is naturally cooled.

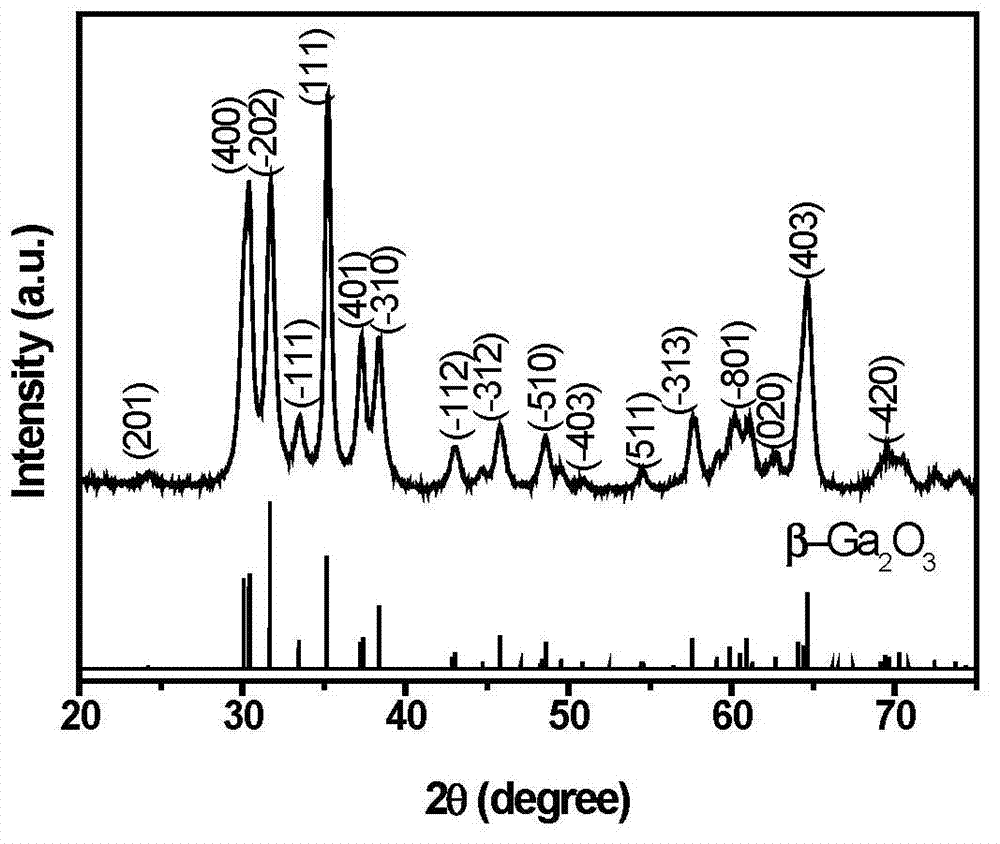

[0052] figure 1 It is the XRD pattern of the product obtained after heating the hydrothermal product at 700°C for 2 hours. Fr...

Embodiment 2

[0055] Example 2: Synthesis of acicular nanostructure gallium oxide by hydrothermal method

[0056] Preparation of acicular nano-gallium oxide: according to gallium nitrate hydrate (Ga(NO 3 ) 3 wxya 2 O), polyvinyl alcohol (PVA) and water are mixed in a mass ratio of 20:1:200 to form a solution. The pH was adjusted to 6.4 and the solution was heated in a water bath at 90°C for 10 minutes. Then transfer the obtained product to a sealed polytetrafluoroethylene hydrothermal kettle, place it in a constant temperature drying oven, heat it at 200°C for a period of time, take out the hydrothermal kettle, cool it to room temperature, and centrifuge the product in the kettle. The washed and dried powder is placed in a tube furnace, calcined at 700° C. for a period of time under nitrogen atmosphere, and finally the obtained product is naturally cooled.

[0057] Figure 4 It is the XRD pattern of the product obtained after heating the hydrothermal product at 700°C for 2 hours. From...

Embodiment 3

[0060] Example 3: Degradation of perfluorocarboxylic acid by fan-shaped gallium oxide combined with vacuum ultraviolet light

[0061] The photocatalytic degradation of perfluorocarboxylic acid in pure water or wastewater is carried out. The catalyst used is fan-shaped gallium oxide, and the dosage is 0.5g / L. The reaction is carried out in a ring-tube glass photoreactor. An ordinary 14W low-pressure mercury lamp capable of emitting 254nm ultraviolet light (hereinafter referred to as "UV light") and a 14W special low-pressure mercury lamp capable of emitting 185nm vacuum ultraviolet light (hereinafter referred to as "VUV light") were used as light sources. The light source is placed in the middle of the photoreactor and separated from the reaction solution by a quartz sleeve. During the reaction process, the gas is uniformly distributed through the sieve plate at the bottom of the reactor and then enters the reaction solution, and is discharged from the exhaust hole on the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com