Micro-electromechanical system (MEMS) silicon wafer scribing and cutting and structure releasing method

A silicon wafer, dicing and cutting technology, applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve problems such as edge jumping, silicon chip contamination, large internal stress of chips, etc., and achieve high quality High efficiency, improved production efficiency, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

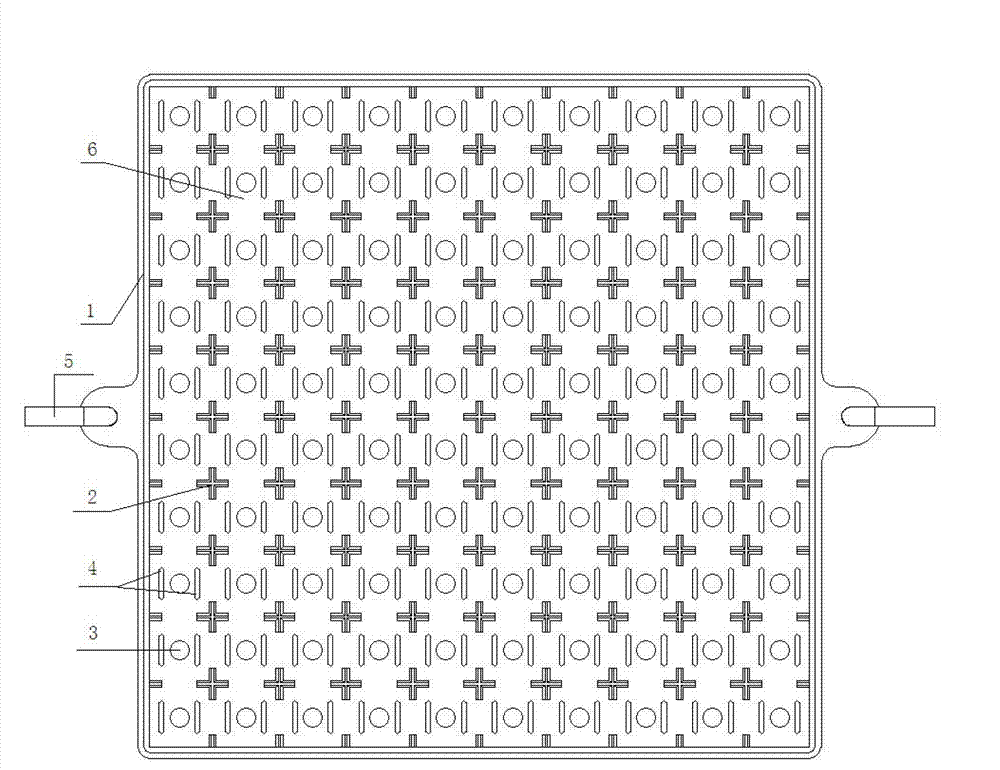

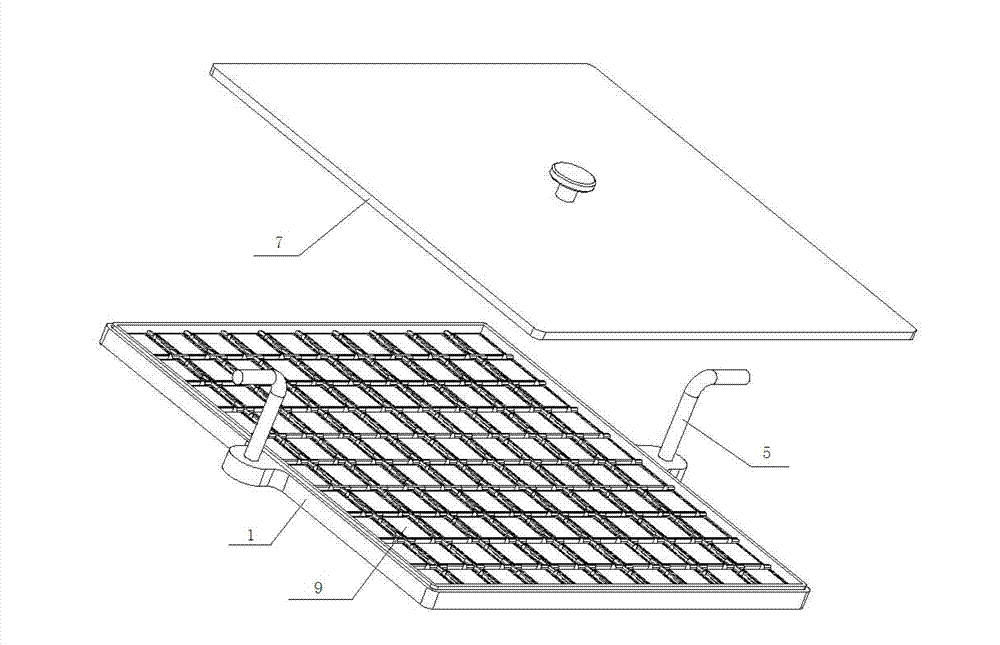

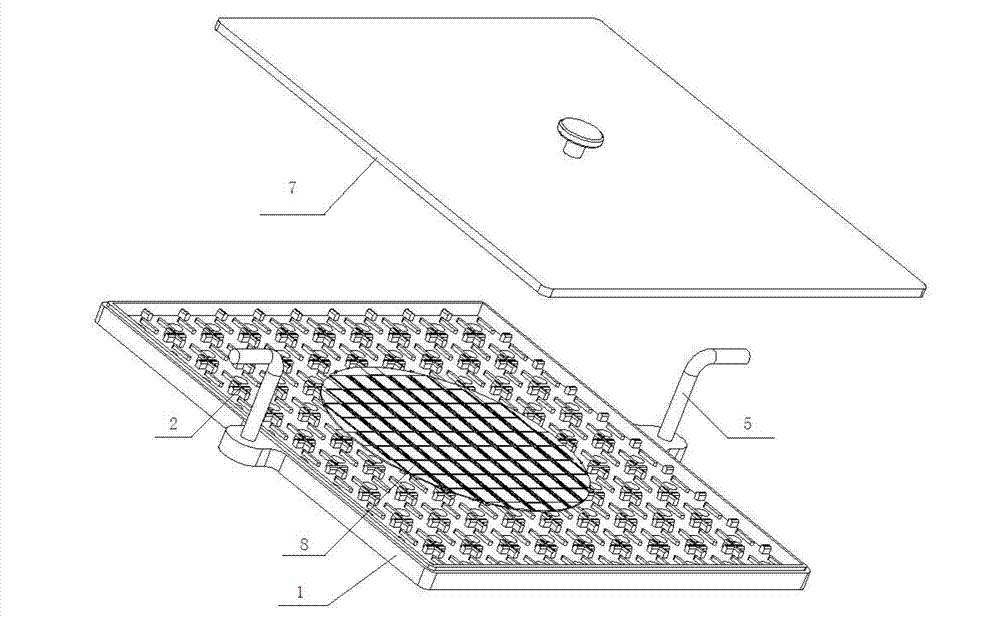

Image

Examples

Embodiment 1

[0041] A MEMS silicon wafer dicing cutting and structure release method, comprising the following steps:

[0042] Step 1: Paste the UV film, paste the UV film on the back of the MEMS silicon wafer; put the front side of the silicon wafer down, the back side up, and put a layer of dust-free filter paper underneath, the size of which is the same as that of the wafer, and place it in the film mounter. right in the middle. Pull out the UV film from the rear reel of the film lamination machine. The length exceeds the patch circular iron ring by 10cm. If the film is partially wrinkled, it needs to be further tightened until the surrounding is even and flat. On the back of the wafer and on the circular iron ring; cut off the UV film beyond the circular iron ring.

[0043] Step 2: For the first scribing, place the silicon wafer with UV film facing up on the scribing table of the dicing machine, set the silicon wafer according to the thickness of the scribing, and set the silicon wafe...

Embodiment 2

[0052] A MEMS silicon wafer dicing cutting and structure release method, comprising the following steps:

[0053] Step 1: Paste the UV film, and paste the UV film on the back of the MEMS silicon wafer; put the front side of the silicon wafer down and the back side up, and put a layer of dust-free filter paper underneath, the size of which is the same as that of the wafer, and place it on the side of the film mounter. right in the middle. Pull out the UV film from the rear reel of the film lamination machine. The length exceeds the patch circular iron ring by 10cm. If the film is partially wrinkled, it needs to be further tightened until the surrounding is even and flat. On the back of the wafer and on the circular iron ring; cut off the UV film beyond the circular iron ring.

[0054] Step 2: For the first scribing, place the silicon wafer with UV film facing up on the scribing table of the dicing machine, set the silicon wafer according to the thickness of the scribing, and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com