Method for producing classical swine fever live vaccine by using microcarrier high-density cell culture technology

A swine fever live vaccine and cell culture technology, applied in the field of veterinary biological products, can solve the problems of poor product uniformity, fluctuating vaccine product quality level, low production efficiency, etc., to achieve improved uniformity and stability, and good immune protection. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Select microcarrier: Fibra Disk from NBS Company.

[0024] (2) Choose a reactor: a 5-liter cell culture tank with BASKET from NBS Company.

[0025] (3) In this example, miniature pig kidney cells (MPK) were selected, and the MPK cells were subcultured in cell culture flasks or spinner bottles at a ratio of 1:2 to 8. Usually, the growth time of each generation of cells was 48 to 72 hours. . When the cell confluency exceeds 80%, inoculate the cells into the bioreactor.

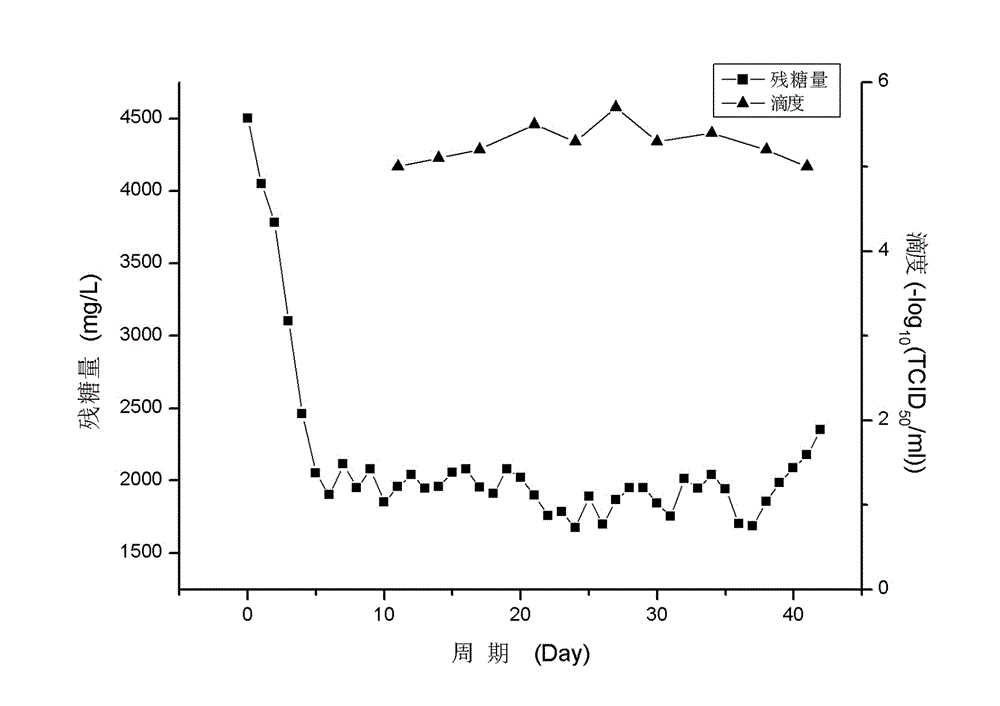

[0026] (4) Inoculate the cells in the bioreactor, with the optimized microcarrier load of 100 grams, after complete attachment, the cell density reaches 1.5×10 6 cells / ml, start to continuously perfuse the medium, and adjust the control conditions of the culture process: growth temperature 36.5-37.5°C, stirring speed 60-120rpm, pH value 7.0-7.4, dissolved oxygen concentration 30-80% and glucose content 1500 ~4500mg / L, the density of cells in the 5L bioreactor stabilized at 14×10 6 ...

Embodiment 2

[0032] (1) Choose a bioreactor: NBS cell lift impeller (CELL LIFT IMPELLER) bioreactor.

[0033] (2) Select microcarrier: Cytodex 1 type microcarrier from GE Company.

[0034] (3) In this example, miniature pig kidney cells (MPK) were selected, and the MPK cells were subcultured in cell culture flasks or spinner bottles at a ratio of 1:2 to 8. Usually, the growth time of each generation of cells was 48 to 72 hours. . When the cell confluency exceeds 80%, inoculate the cells into the bioreactor.

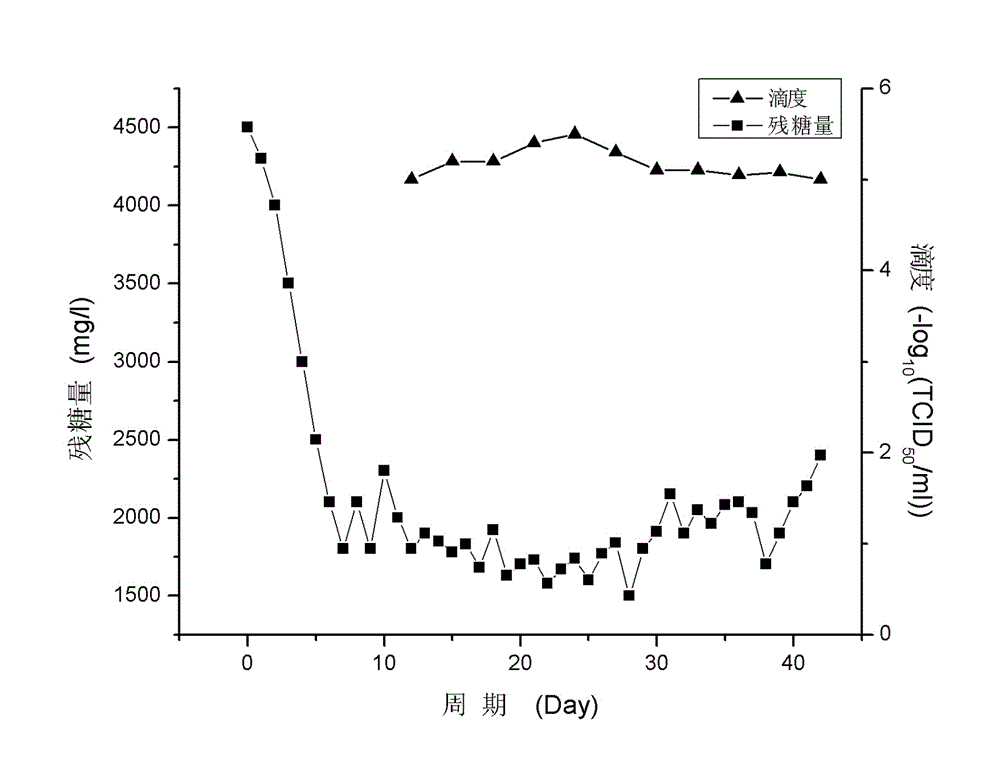

[0035] (4) The suitable range of microcarrier Cytodex 1 in the reactor is 10-25 grams per liter. This time, 20 grams per liter was used, and the density after inoculation of cells was 1.2×10 6 cells / ml, and add an appropriate amount of medium, start continuous perfusion of medium, adjust the control conditions of the culture process: growth temperature 36.5 ~ 37.5 ℃, stirring speed 30 ~ 70rpm, pH value 7.0 ~ 7.4, dissolved oxygen concentration 20 ~ 50% and glucose conte...

Embodiment 3

[0041] (1) Choose a bioreactor: NBS cell lift impeller (CELL LIFT IMPELLER) bioreactor.

[0042] (2) Select microcarrier: Cytodex 3 type microcarrier from GE Company.

[0043] (3) In this example, miniature pig kidney cells (MPK) were selected, and the MPK cells were subcultured in cell culture flasks or spinner bottles at a ratio of 1:2 to 8. Usually, the growth time of each generation of cells was 48 to 72 hours. . When the cell confluency exceeds 80%, inoculate the cells into the bioreactor.

[0044] (4) The suitable range of microcarrier Cytodex 3 in the reactor is 10-20 grams per liter, and 15 grams per liter is used this time, and the density after inoculation of cells is 0.9×10 6 cells / ml, and add an appropriate amount of medium, start continuous perfusion of medium, adjust the control conditions of the culture process: growth temperature 36.5~37.5℃, stirring speed 50~80rpm, pH value 7.0~7.4, dissolved oxygen concentration 25~ 50% and glucose content of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com