Compound stabilizing agent, fermented yogurt comprising compound stabilizing agent, and preparation method of fermented yogurt

A technology for compounding stabilizer and content, applied in the direction of milk preparations, dairy products, applications, etc., can solve the problems of product texture and taste change, product instability, rough texture, etc., to achieve close taste, good tissue state, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

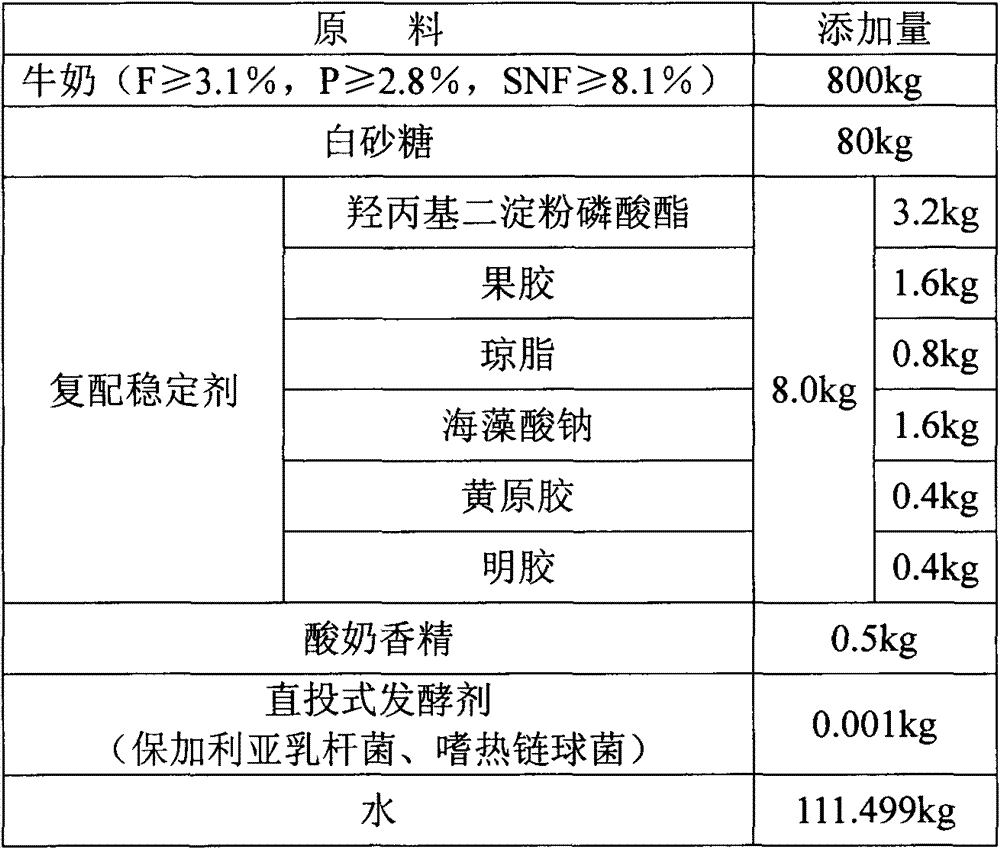

[0058] Embodiment 1 room temperature yoghurt product

[0059] Product formula (calculated per ton of final product):

[0060]

[0061] The preparation method comprises the following steps:

[0062] 1) Antibiotic-free milk with no less than 3.1% fat and no less than 2.8% protein should be pre-sterilized (137°C, 4s) and stored in a cleaned and sterilized milk storage tank, and refrigerated before use (storage temperature 6°C );

[0063] 2) Heat the milk in step 1) to 50°C to 55°C through a plate heat exchanger, and pass the acetylated distarch phosphate, pectin, gelatin, sodium alginate, xanthan gum, gelatin, and white sugar through a water powder mixer Add it to the above milk, stir at constant temperature for 20 minutes to make it evenly mixed;

[0064] 3) Homogenize the mixed solution obtained in step 2), the homogenization temperature is 60°C, and the pressure is successively 15MPa and 5MPa for two-stage homogenization;

[0065] 4) The homogenized liquid in step 3) is...

Embodiment 2

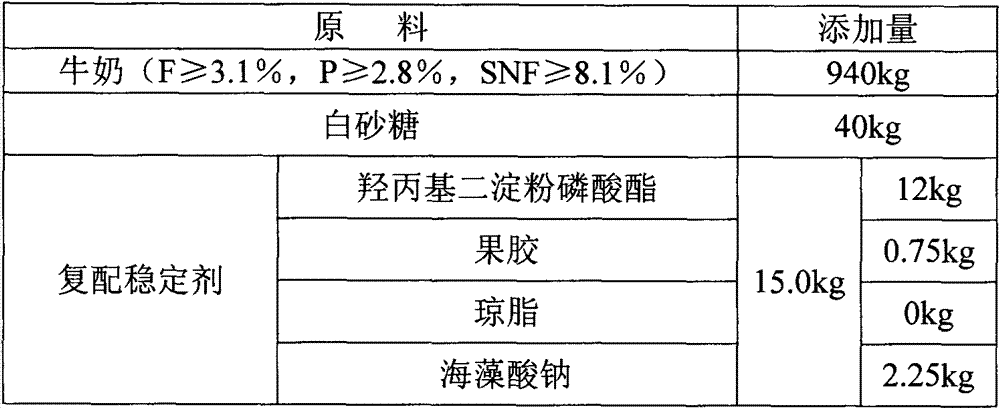

[0071] Embodiment 2 room temperature yoghurt product

[0072] Product formula (calculated per ton of final product):

[0073]

[0074]

[0075] The preparation method comprises the following steps:

[0076] 1) Antibiotic-free milk with no less than 3.1% fat and no less than 2.8% protein should be pre-sterilized (137°C, 4s) and stored in a cleaned and sterilized milk storage tank, and refrigerated before use (storage temperature 4°C );

[0077] 2) Heat the milk in step 1) to 50°C-55°C through a plate heat exchanger, acetylate distarch phosphate, pectin, gelatin, sodium alginate, xanthan gum, gelatin, white sugar and sweetener Add it into the above-mentioned milk through a water-powder mixer, and stir at a constant temperature for 20 minutes to make it evenly mixed;

[0078] 3) Homogenize the mixed solution obtained in step 2), the homogenization temperature is 70°C, and the pressure is successively 18MPa and 2MPa;

[0079] 4) The homogenized liquid in step 3) is paste...

Embodiment 3

[0085] Embodiment 3 room temperature yoghurt product

[0086] Product formula (calculated per ton of final product):

[0087]

[0088] The preparation method comprises the following steps:

[0089] 1) Antibiotic-free milk with no less than 3.1% fat and no less than 2.8% protein should be pre-sterilized (137°C, 4s) and stored in a cleaned and sterilized milk storage tank, and refrigerated before use (storage temperature 4°C );

[0090] 2) Heat the milk in step 1) to 50°C-55°C through a plate heat exchanger, and mix acetylated distarch phosphate, pectin, gelatin, sodium alginate, xanthan gum, gelatin, and sweetener with water powder Add it into the above milk, stir at constant temperature for 20 minutes, and make it evenly mixed;

[0091] 3) Homogenize the mixed solution obtained in step 2), the homogenization temperature is 70°C, and the pressure is successively 18MPa and 2MPa;

[0092] 4) The homogenized liquid in step 3) is pasteurized for the first time, the steriliza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com