Method and device for quickly measuring coal seam gas pressure by upward long-distance drilling

A coal seam gas pressure and rapid measurement technology, which is applied in measurement, earthwork drilling, wellbore/well components, etc., can solve the problems of difficult to measure coal seam gas pressure value, long pressure stabilization time, slow cement mortar solidification, etc., to achieve The effect of reducing the amount of roadway engineering, fast pressure measurement, and improving air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

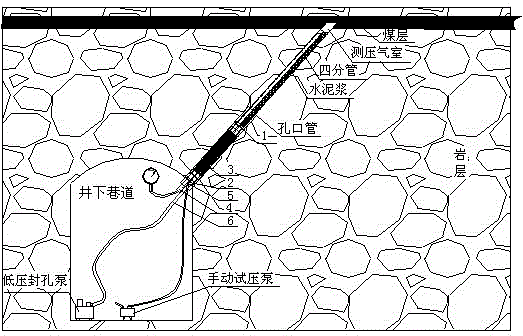

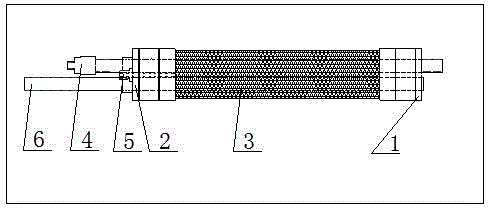

[0028] An example of the present invention will be further described below in conjunction with accompanying drawing:

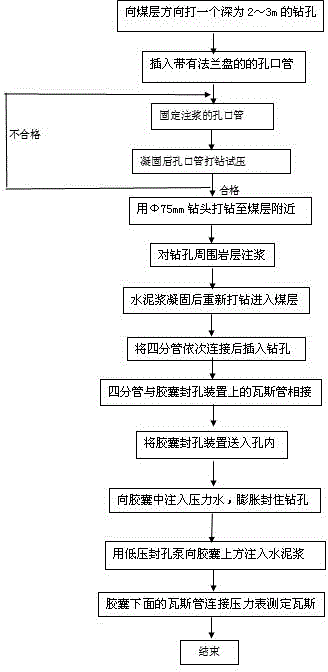

[0029] The method for quickly measuring coal seam gas pressure by upward long-distance drilling of the present invention, before measuring the coal seam gas pressure, first performs high-pressure grouting on the rock layer below the coal seam, which can avoid the influence of cracks in the rock layer or underground water pressure on the pressure measurement results, Specific steps are as follows:

[0030] Step 1: Drill a borehole with a diameter of 120-150mm and a depth of 2-3m in the direction of the upper coal seam in the underground roadway as a pressure measurement hole, and send a Ф115×5mm orifice pipe with a high-pressure flange into the borehole In the hole, the exposed length of the orifice tube is 200-300mm;

[0031] Step 2: Use a high-pressure grouting pump to mix the mortar prepared according to the mass ratio of water: ash = 0.75: 1 with water gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com