Cleaning agent capable of cleaning carbon deposition of engine

A cleaning agent and engine technology, applied in the field of polymer chemistry, can solve the problems of reducing engine power, metal corrosion of fuel system, straining cylinder wall, etc., to achieve the effect of improving power, reducing fuel consumption and strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

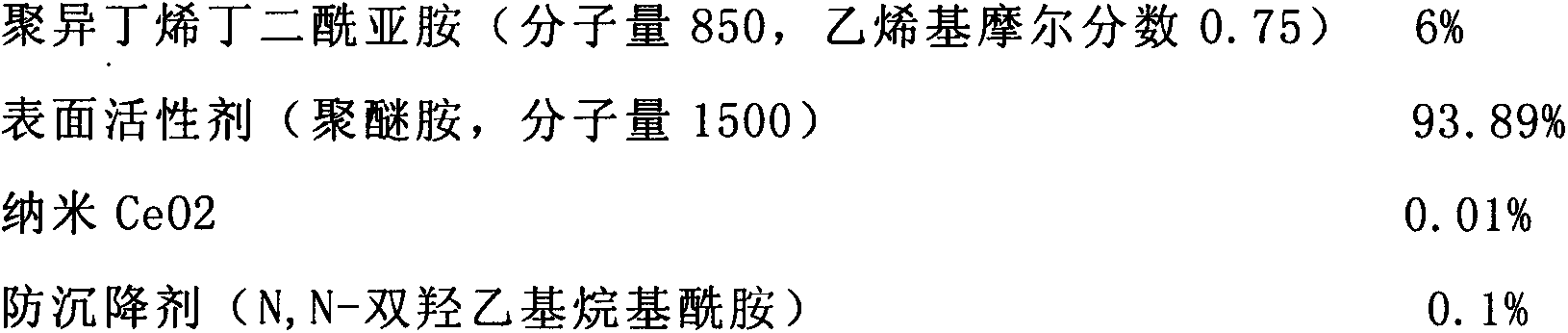

[0027] A cleaning agent capable of cleaning engine carbon deposits, the mass percentage of each component:

[0028]

[0029] Disperse the above materials with a high-speed 800 rpm disperser for 1 hour, and then oscillate with 30KHz ultrasonic waves for 0.5 hours.

[0030] How to use: Mix 200ml cleaning agent into the fuel tank with 40-50L gasoline.

Embodiment 2

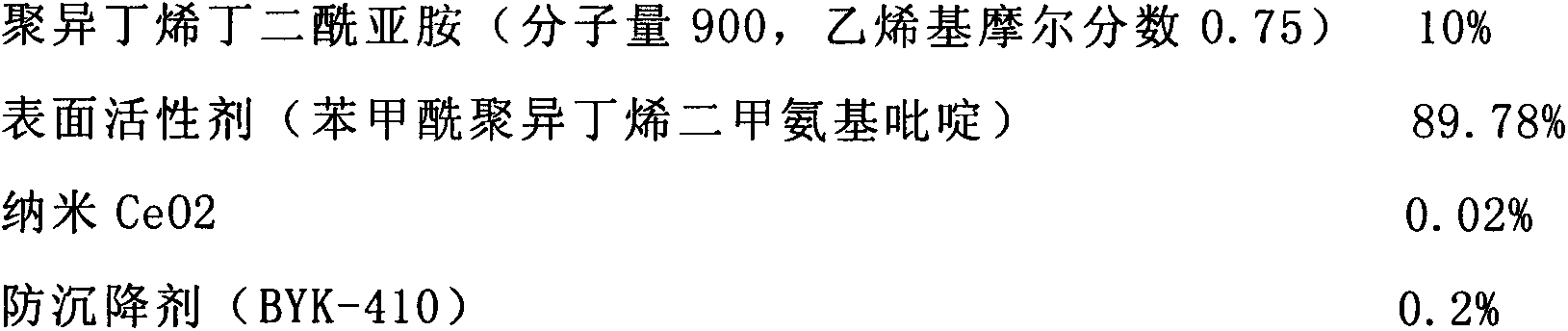

[0032] A cleaning agent capable of cleaning engine carbon deposits, the mass percentage of each component:

[0033]

[0034] Disperse the above materials with a high-speed 1000 rpm disperser for 2 hours, and then oscillate with 30KHz ultrasonic waves for 0.5 hours.

[0035] How to use: Mix 200ml cleaning agent into the fuel tank with 40-50L gasoline.

Embodiment 3

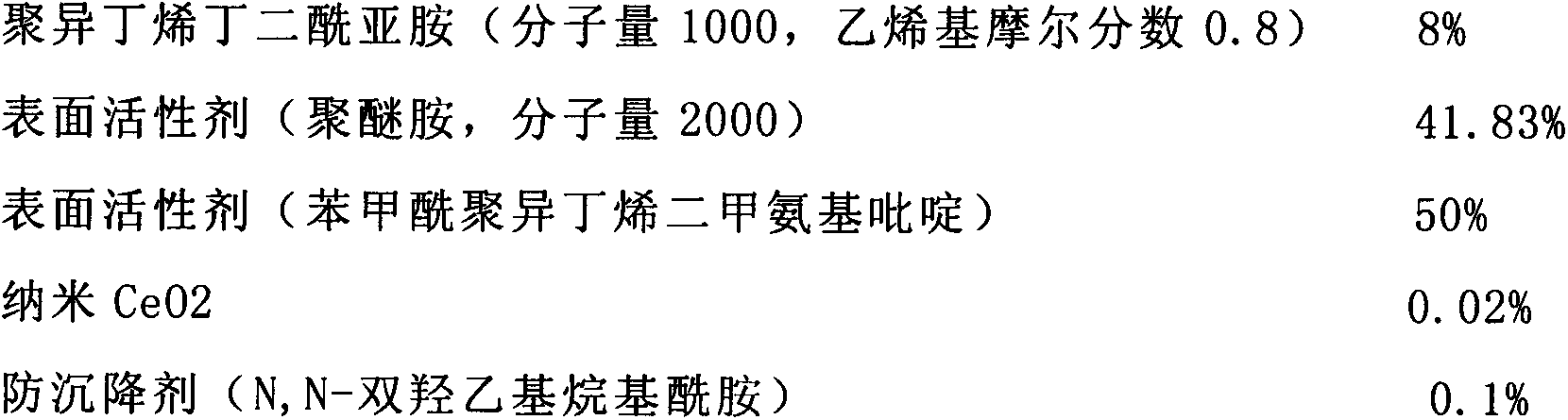

[0037] A cleaning agent capable of cleaning engine carbon deposits, the mass percentage of each component:

[0038]

[0039]

[0040] Disperse the above materials with a high-speed 2500 rpm disperser for 1 hour, and then oscillate with 30KHz ultrasonic waves for 0.8 hours.

[0041] How to use: Mix 200ml cleaning agent into the fuel tank with 40-50L gasoline.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com