Method for improving anaerobic energy production efficiency of algae raw material through bacterial degradation biological pretreatment

A biological pretreatment and algae technology, which is applied in the field of biotechnology and renewable energy, can solve the problems of decreased anaerobic gas production rate, enzymes cannot be reused, and high processing costs, so as to achieve high raw material utilization rate, improve energy conversion efficiency, The effect of promoting hydrolysis and breaking the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for improving the anaerobic production efficiency of algae raw materials through bacteriolysis biological pretreatment:

[0028] (1) Centrifuge and concentrate the liquid of Scenedesmus subspicatus for later use.

[0029] Add 500ml of nutrient salt solution to the concentrated algae liquid, insert the pre-cultivated cellulose-degrading bacteria Clostridium sp. seed liquid, and control the temperature at about 55°C for pretreatment; Clostridium sp. The volume ratio of the solution was 5%.

[0030] The nutrient salt solution formula is per liter including NH 4 Cl, 1g; K 2 HPO 4 , 2g; KH 2 PO 4 , 3.3g; CaCl 2 , 0.1g; MgCl 2 ·6H 2 O, 0.2g; yeast powder, 0.1g; FeSO 4 ·7H 2 O, 1 mg; MnCl 2 4H 2 O, 1 mg; ZnCl 2 , 1 mg; CuCl 2 2H 2 O, 0.2 mg; NaMoO 4 2H 2 O, 1 mg in water; pH=7.0.

[0031] (2) After 20 hours of incubation and incubation in the dark, the TOC in the solution increased by 284 mg / L, but the total amount of ethanol and volatile fatty acids...

Embodiment 2

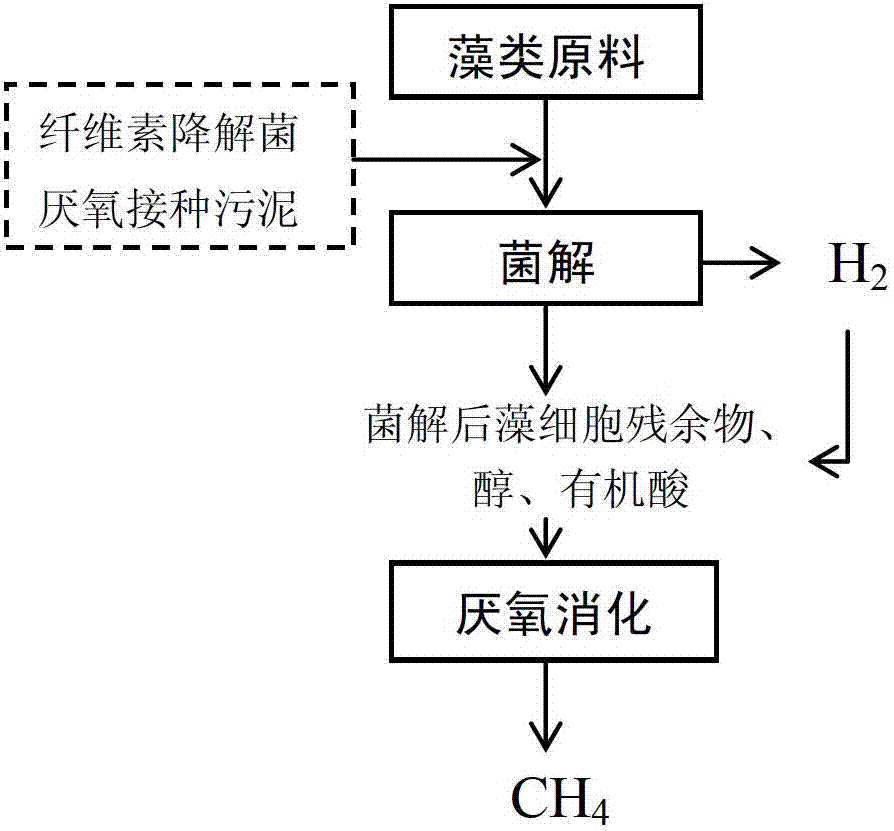

[0033] A method for improving the anaerobic production efficiency of algae raw materials through bacteriolysis biological pretreatment, such as figure 1 Shown:

[0034] (1) Centrifuge and concentrate the algae liquid of Chlorella vulgaris for later use.

[0035](2) Add 500ml of nutrient salt solution to the concentrated algae solution, insert the pre-cultivated Clostridium sp. seed solution, and insert anaerobic granular sludge at the same time, and control the temperature at about 55°C for anaerobic fermentation.

[0036] The formula of nutrient salt solution is as follows: NH 4 Cl, 0.5g; K 2 HPO 4 , 1g; KH 2 PO 4 , 1.7g; CaCl 2 , 0.05g; MgCl 2 ·6H 2 O, 0.1g; yeast powder, 0.05g; FeSO 4 ·7H 2 O, 0.5 mg; MnCl 2 4H 2 O, 0.5 mg; ZnCl 2 , 0.5mg; CuCl 2 2H 2 O, 0.1 mg; NaMoO 4 2H 2 O, 0.5mg; water, 500ml; pH=7.0.

[0037] The anaerobic granular sludge is taken from the anaerobic internal circulation reactor, which contains highly active methanogenic bacteria, an...

Embodiment 3

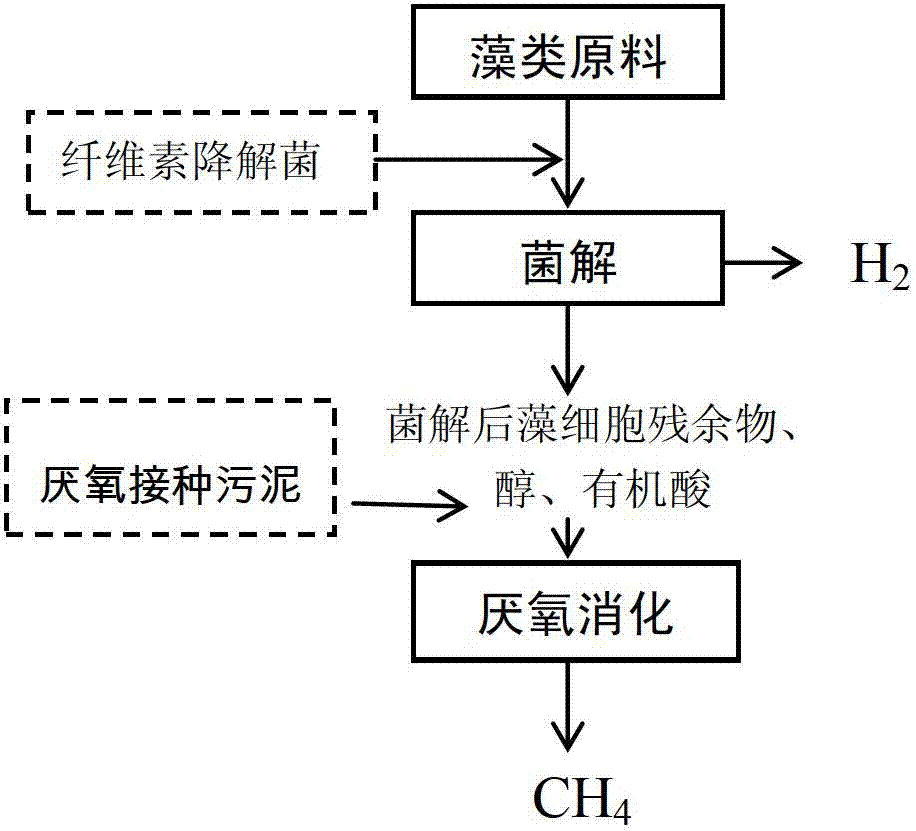

[0039] A method for improving the anaerobic production efficiency of algae raw materials through bacteriolysis biological pretreatment, such as figure 2 Shown:

[0040] (1) Centrifuge and concentrate the algae liquid of Chlorella vulgaris for later use.

[0041] Add 500ml of nutrient salt solution to the concentrated algae solution, insert the pre-cultivated Clostridium sp. seed solution, and control the temperature at about 55°C for pretreatment.

[0042] (2) After culturing for 4 days, insert anaerobic granular sludge and carry out anaerobic fermentation at about 55°C.

[0043] The formula of nutrient salt solution is as follows: NH 4 Cl, 0.5g; K 2 HPO 4 , 1g; KH 2 PO 4 , 1.7g; CaCl 2 , 0.05g; MgCl 2 ·6H 2 O, 0.1g; yeast powder, 0.05g; FeSO 4 ·7H 2 O, 0.5 mg; MnCl 2 4H 2 O, 0.5 mg; ZnCl 2 , 0.5mg; CuCl 2 2H 2 O, 0.1 mg; NaMoO 4 2H 2 O, 0.5 mg; water, 500 ml; pH 7.0.

[0044] (3) After the synchronous hydrogen production culture by bacterial hydrolysis, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com