ABS/POM alloy and preparation method thereof

An alloy and weight percentage technology, applied in the field of ABS/POM alloy and its preparation, can solve problems such as poor compatibility, achieve the effects of simple preparation process, improved impact performance and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of ABS grafted maleic anhydride of the present invention is as follows; Mix the raw materials of the following weight percentages, and extrude the reaction at a temperature of 140-200 ° C to obtain a compatibilizer,

[0047]

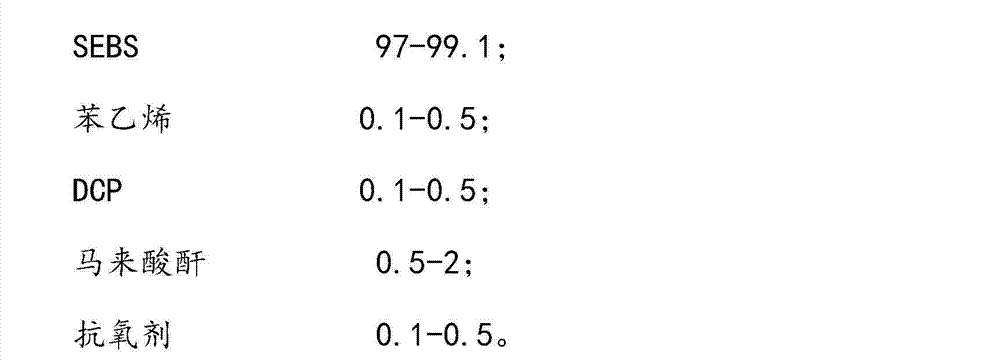

[0048] The preparation method of SEBS grafted maleic anhydride is as follows; the raw materials in the following weight percentages are mixed, and the extrusion reaction is carried out at a temperature of 160-200 ° C to obtain a compatibilizer,

[0049]

[0050] Because the compatibility of ABS and POM is very bad, but use ABS grafted maleic anhydride and SEBS grafted maleic anhydride as compatibilizer in the present invention, make the compatibility of its alloy be improved, in the TPU as a toughening agent makes the whole alloy have a significant improvement in toughness.

[0051] The preparation process of ABS / POM alloy of the present invention is as follows:

[0052] (1) Weigh raw materials according to weight per...

Embodiment 1

[0066] Polyoxymethylene 79.3%; nucleating agent - long chain carboxylic acid calcium salt 0.1%; ABS 10%; stabilizer - melamine urate 0.1%; compatibilizer 5%; toughening agent - polyurethane elastomer 5%; antioxidant Agent 0.2%; lubricant 0.3%. It is extruded by a twin-screw extruder with a melting temperature of 150-200°C and pelletized.

[0067] The temperature of each section is: 150°C in the first zone, 180°C in the second zone, 185°C in the third zone, 190°C in the fourth zone, and 180°C in the fifth zone. The conveying time of the mixture in the screw is 90 seconds.

Embodiment 2

[0069] Polyoxymethylene 74.3%; nucleating agent - long chain carboxylic acid calcium salt 0.1%; ABS 10%; stabilizer - melamine urate 0.1%; compatibilizer 5%; toughening agent - polyurethane elastomer 10%; antioxidant 0.2% agent; 0.3% lubricant; extruded by a twin-screw extruder with a melting temperature of 150-200°C, and pelletized.

[0070] The temperature of each section is: 150°C in the first zone, 180°C in the second zone, 185°C in the third zone, 190°C in the fourth zone, and 180°C in the fifth zone. The conveying time of the mixture in the screw is 90 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com