A kind of strengthened vegetable protein membrane material and preparation method thereof

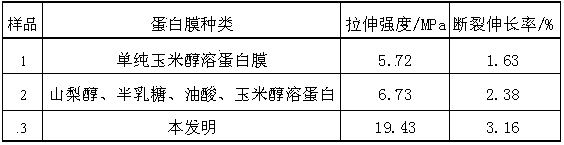

A plant protein and film material technology, applied in the direction of flexible coverings, packaging, wrapping paper, etc., can solve the problems of poor stretchability and ductility, brittle and fragile protein film, easy to absorb moisture and soften, etc., to achieve the goal of packaging Strong, increase density, reduce brittle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of composite enhancer

[0024] Oleic acid 30g / 100g, sorbitol 35g / 100g, galactose 35g / 100g, under the condition of 20 ℃, shear mixing homogenization treatment, shear mixing speed 15r / min, time 3min.

[0025] (2) Plant protein modification treatment

[0026] Pure and impurity-free corn protein and soybean protein were denatured by heat and humidity at 105°C for 10 minutes, respectively, and purified water was added at a ratio of 1:4 by mass to water, and ground and homogenized to obtain a slurry that could completely pass through a sieve with an aperture of 75 μm. Dried to a water content of 5g / 100g, pulverized to obtain zein fine powder and soybean protein fine powder with a particle size of less than 61 μm, taking 85g / 100g of zein fine powder and 15g / 100g of soybean protein fine powder and mixing evenly to obtain a composite vegetable protein fine powder for later use;

[0027] (3) Preparation of enhanced plant protein film

[0028] Take the compound v...

Embodiment 2

[0030] (1) Preparation of composite enhancer

[0031] Oleic acid 40g / 100g, sorbitol 30g / 100g, galactose 30g / 100g, under the condition of 30 ℃, shear mixing homogenization treatment, shear mixing speed 30r / min, time 6min;

[0032] (2) Plant protein modification treatment

[0033] Pure and impurity-free corn protein and soybean protein were denatured by heat and humidity at 120°C for 5 minutes, respectively, and purified water was added at a ratio of 1:4 by mass to water, and ground and homogenized to obtain a slurry that could completely pass through a sieve with an aperture of 75 μm. Dried to a water content of 10g / 100g, pulverized to obtain fine corn protein powder and soybean protein fine powder with a particle size of less than 61 μm, take 95g / 100g of corn protein fine powder and 5g / 100g of soybean protein fine powder and mix evenly to obtain a composite vegetable protein fine powder for later use ;

[0034] (3) Preparation of enhanced plant protein film

[0035] Take th...

Embodiment 3

[0037] (1) Preparation of composite enhancer

[0038] Oleic acid 35g / 100g, sorbitol 32.5g / 100g, galactose 32.5g / 100g, under the condition of 25 ℃, shear mixing homogenization treatment, shear mixing speed 17.5r / min, time 4.5min;

[0039] (2) Plant protein modification treatment

[0040]Pure and impurity-free corn protein and soybean protein were denatured at 112.5°C for 7.5 minutes, respectively, and purified water was added according to the mass-to-water ratio of 1:4, and they were ground and homogenized to obtain a slurry that could completely pass through a sieve with an aperture of 75 μm. , dried to a water content of 7.5g / 100g, and crushed to obtain fine corn protein powder and fine soybean protein powder with a particle size of less than 61 μm; take 90 g / 100 g of fine corn protein powder and 10 g / 100 g of soybean protein fine powder and mix evenly to obtain a fine compound vegetable protein powder powder spare;

[0041] (3) Preparation of enhanced plant protein film

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com