Phosphor silicon nitrogen ternary coordination fire retardant, preparation method and application

A flame retardant material, vinyl silazane technology, applied in the field of functional flame retardants, can solve the problems of complex preparation process, no batch products, and supply, etc., and achieve the effect of excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In a reactor equipped with nitrogen inlet, condenser and thermometer, 4.04g (0.02mol) of diphenylphosphine oxide (DPPO) and 1.85g (0.01mol) of 1,1,3,3-tetramethyl- Add 1,3-divinyldisilazane to 10ml of acetone in turn, stir at 15°C until clear and transparent, under the protection of nitrogen, control the temperature at 15°C, add 4ml of 0.5M tripropyl Boron tetrahydrofuran solution; after the dropwise addition, the addition reaction was stopped at 15°C for 1 hour, the solvent was evaporated, washed with water several times, and dried to obtain 5.08 g of white solid (Compound 1), with a yield of 86%.

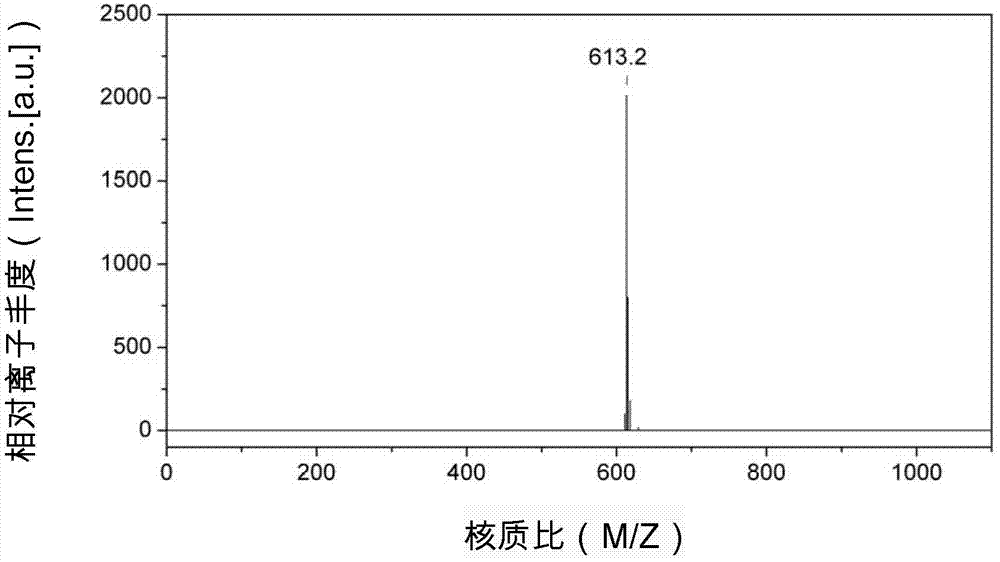

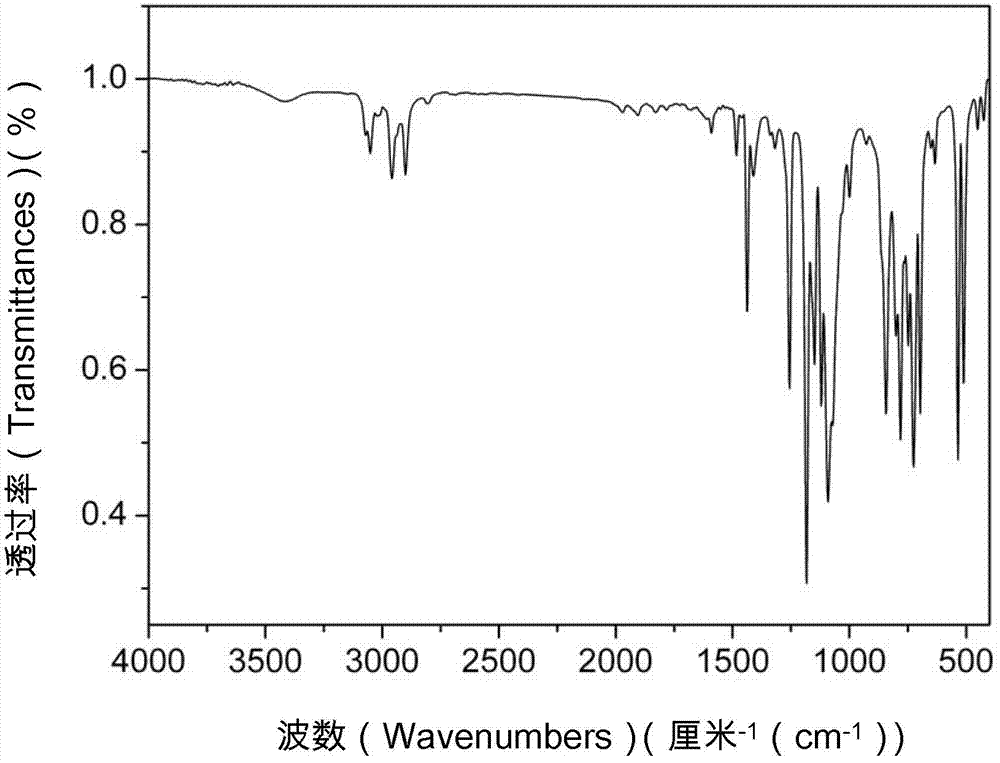

[0040] The structural detection data of this compound are as follows (the NMR spectrum, NMR carbon spectrum, NMR phosphorus spectrum, NMR silicon spectrum, mass spectrum (MALDI-TOF) figure, infrared spectrum and DSC spectrum of this compound are respectively as follows figure 1 , figure 2 , image 3 , Figure 4 Figure 5 , Figure 6 and Figure 7 shown.

[0041] Mel...

Embodiment 2

[0051] In a reactor equipped with nitrogen inlet, condenser and thermometer, 41.4g (0.205mol) of diphenylphosphine oxide (DPPO) and 18.5g (0.1mol) of 1,1,3,3-tetramethyl- Add 1,3-divinyldisilazane to 100ml of acetone in turn, stir at 15°C until clear and transparent, under nitrogen protection, control the temperature at 15°C, add 40ml of 0.5M tripropyl Boron tetrahydrofuran solution; after the dropwise addition, the addition reaction was stopped at 15°C for 10 hours, the solvent was evaporated, washed with water several times, and dried to obtain 53.7 g of white solid (compound 2), with a yield of 88%.

[0052] The structural detection data of this compound are as follows (the NMR spectrum, NMR carbon spectrum, NMR phosphorus spectrum, NMR silicon spectrum, mass spectrum (MALDI-TOF) figure, infrared spectrum and DSC spectrum of this compound are respectively as follows figure 1 , figure 2 , image 3 , Figure 4 Figure 5 , Figure 6 and Figure 7 shown.

[0053] Meltin...

Embodiment 3

[0062] In a reactor equipped with nitrogen inlet, condenser and thermometer, 4.04g (0.02mol) of diphenylphosphine oxide (DPPO) and 1.85g (0.01mol) of 1,1,3,3-tetramethyl- Add 1,3-divinyldisilazane to 10ml of tetrahydrofuran in turn, stir at 15°C until clear and transparent, under nitrogen protection, control the temperature at 15°C, add 5ml of tributyl tributyl with a concentration of 0.5M dropwise within 0.5 hours Boron n-hexane solution; after the dropwise addition, the addition reaction was stopped at 15°C for 2 hours, the solvent was evaporated, washed with water several times, and dried to obtain 4.95 g of white solid (compound 3), with a yield of 84%.

[0063] The structural detection data of this compound are as follows (the NMR spectrum, NMR carbon spectrum, NMR phosphorus spectrum, NMR silicon spectrum, mass spectrum (MALDI-TOF) figure, infrared spectrum and DSC spectrum of this compound are respectively as follows figure 1 , figure 2 , image 3 , Figure 4 Figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nmr | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Hydroxyl equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com