Cultivation substrate of edible mushroom, preparation method of cultivation substrate and cultivation method of edible mushroom

A technology for cultivating substrates and edible fungi, applied in the directions of botanical equipment and methods, applications, fertilizer mixtures, etc., can solve the problems of high energy consumption of equipment operation, high sterilization cost, large waste water treatment facilities, etc., and reduce the discharge of waste residue and waste water. , good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

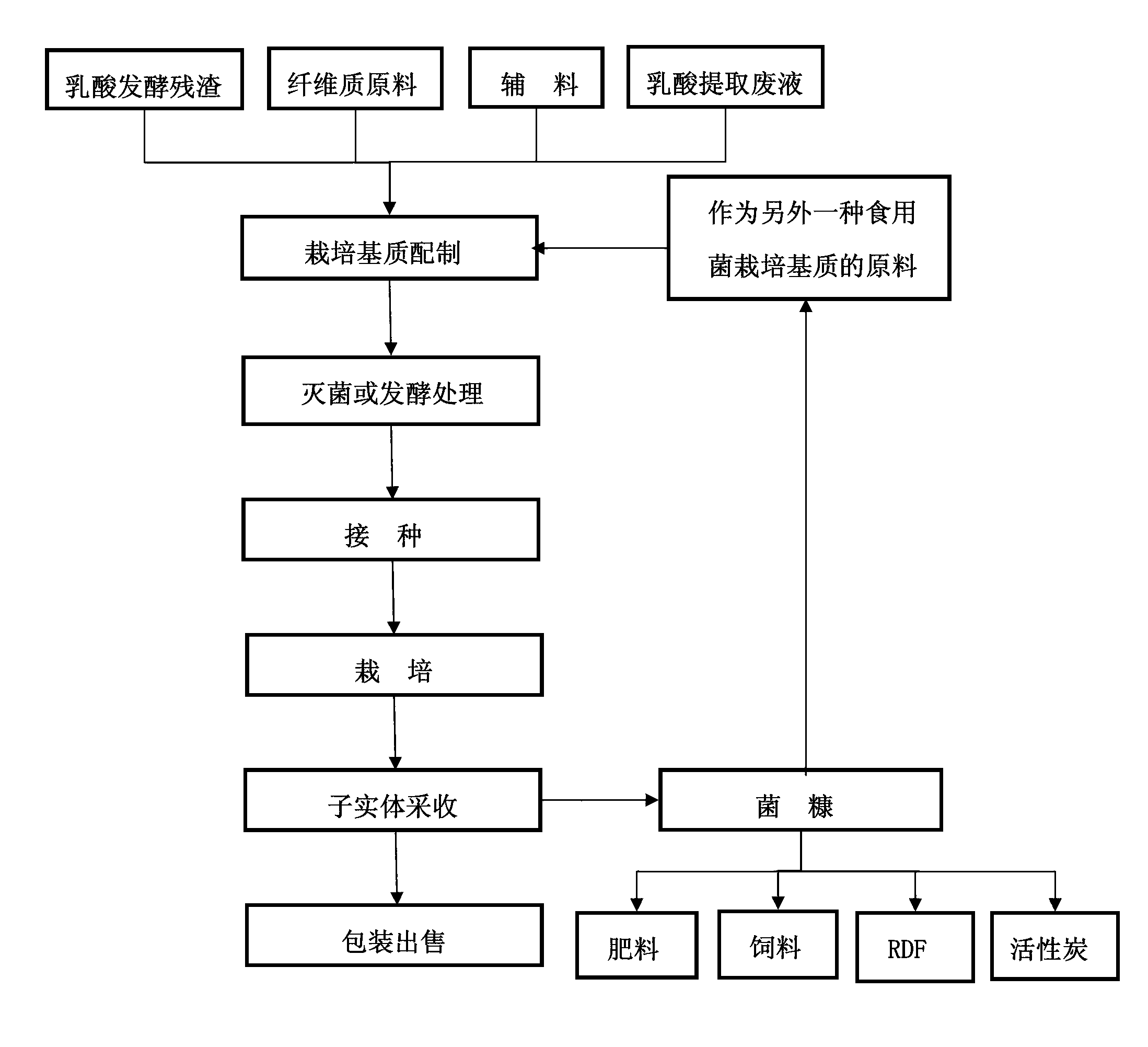

Method used

Image

Examples

Embodiment 1

[0024] 1. Preparation of cultivation substrate

[0025] First soak 54kg of rice straw in lime water with a mass fraction of 4% for more than 8 hours, drain it, and cut the soaked rice straw to 3cm, then mix the rice straw with 40kg of lactic acid fermentation residue, 1kg of gypsum powder, 1kg of sucrose, 4kg of lime is mixed to form a dry material, and then the lactic acid extraction waste liquid is added for mixing to obtain a mixture. The added lactic acid extraction waste liquid makes the water content of the mixture 60%. Carry out sub-packaging, each fungus bag is 0.5kg, one end of the fungus bag is tied tightly with a rope, and sterilized at a temperature of 126°C for 2 hours. The PH value of the sterilized mixture is between 6 and 7.5, which is the edible fungi. Cultivation substrate.

[0026] 2. Cultivation of Pleurotus ostreatus

[0027] (1) Put the sterilized cultivation medium in the inoculation room, and sterilize it by ultraviolet light for 1 hour. When the temp...

Embodiment 2

[0032] 1. Preparation of cultivation substrate

[0033] First, soak 64kg of straw in lime water with a mass fraction of 4% for 8 hours, drain it, and cut the soaked straw to 3cm, then mix the chopped straw with 30kg of lactic acid fermentation residue, 1kg of gypsum powder, 1kg of sucrose, and 4kg of sucrose. Lime is mixed to form a dry material, and then lactic acid extraction waste liquid is added for mixing to obtain a mixture. The added lactic acid extraction waste liquid makes the water content of the mixture 65%. Separately pack, each fungus bag is 0.6kg, one end of the fungus bag is tied tightly with a rope, and then sterilized at a temperature of 128°C for 1.5h, the PH value of the sterilized mixture is between 6 and 7.5, which is edible fungus cultivation substrate.

[0034] 2. Cultivation of Pleurotus ostreatus

[0035] (1) Place the sterilized cultivation medium in the inoculation room and sterilize it with ultraviolet light for 1 hour. When the temperature of the...

Embodiment 3

[0040] 1. Preparation of cultivation substrate

[0041] First, soak 69kg of rice straw in lime water with a mass fraction of 4% for 8 hours, drain it, cut the soaked rice straw to 3cm, then mix the chopped rice straw with 25kg of lactic acid fermentation residue, 5kg of lime, and 1kg of superphosphate to form Dry material, then add lactic acid extraction waste liquid and mix to obtain the mixture, the added lactic acid extraction waste liquid makes the water content of the mixture 65%, the mixture is packed with a polypropylene bacteria bag with a width of 17cm and a length of 37cm, Each fungus bag contains 0.5kg, and the fungus bag is sealed with a waterproof collar, and then sterilized at a temperature of 126°C for 2 hours. The PH value of the sterilized mixture is between 7.5 and 9, which is the cultivation substrate of edible fungi.

[0042] 2. Cultivation of Straw Mushrooms

[0043] (1) Place the sterilized cultivation medium in the inoculation box and sterilize it with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com