Processing method for ultra-high strength steel axis parts

An ultra-high-strength, high-strength component technology, which is applied in metal processing equipment, machine tools designed for grinding the rotating surface of workpieces, manufacturing tools, etc., can solve problems such as low processing efficiency, many processing procedures, and large grinding force, and achieve Improve processing accuracy and processing efficiency, reduce burns and hardening, reduce generation and temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

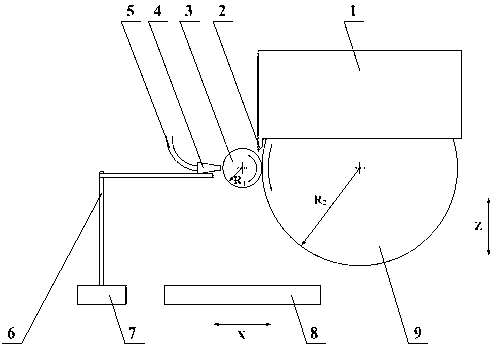

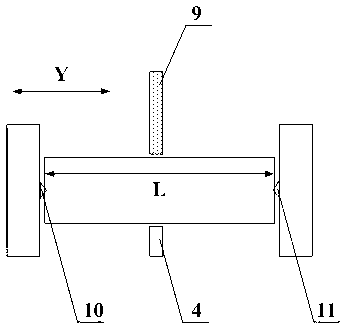

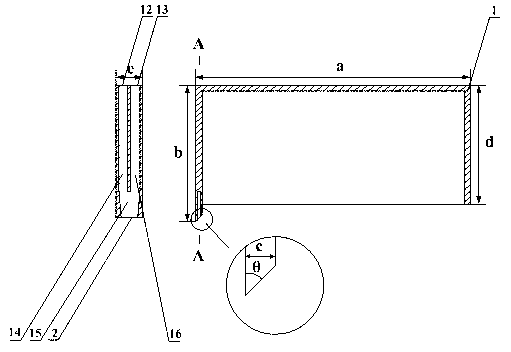

[0021] 1. Device setting and part clamping: the ultra-high-strength steel shaft parts 3 to be processed with a length of 100mm, a radius of 50mm, and a grade of 30Cr3SiNiMoVA are clamped on a MKS1332 / 1000 high-speed external machine through the top 10 and top 11. On the circular grinder, the distance between the axis of the part and the table 8 is 300mm. The nitrogen nozzle 4 and the CBN grinding wheel 9 are arranged oppositely, and are respectively located on both sides of the part 3 to be processed. The width of the nitrogen nozzle 4 spout is 10 mm, and the height is 1 mm. The outer diameter of the CBN grinding wheel 9 is 500mm and the width is 10mm. A nitrogen nozzle 4 is arranged on the left side of the part 3 to be processed, and the nitrogen nozzle 4 is supplied with nitrogen through an air supply hose 5 . Nitrogen is sprayed onto the part 3 to be processed through a nitrogen nozzle 4 , and the nitrogen nozzle 4 is supported by a nitrogen nozzle bracket 6 . The nitrog...

Embodiment 2

[0026] 1. Device setting and parts clamping: the ultra-high strength steel shaft parts 3 to be processed with a length of 200mm, a radius of 60mm, and a grade of 40CrMnSiMoVA are clamped on a MKS1332 / 1000 high-speed external machine through the top 10 and top 11. On the circular grinder, the distance between the axis of the part and the table 8 is 300mm. The nitrogen nozzle 4 and the CBN grinding wheel 9 are arranged oppositely, and are respectively located on both sides of the part 3 to be processed. The width of the nitrogen nozzle 4 spout is 15mm, and the height is 1mm. The outer diameter of the CBN grinding wheel 9 is 450mm, and the width is 15mm. A nitrogen nozzle 4 is arranged on the left side of the part 3 to be processed, and the nitrogen nozzle 4 is supplied with nitrogen through an air supply hose 5 . Nitrogen is sprayed onto the part 3 to be processed through a nitrogen nozzle 4 , and the nitrogen nozzle 4 is supported by a nitrogen nozzle bracket 6 . The nitroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com