Method for welding composite bearing band of soft iron mixed with pure copper, and structure of composite bearing band

A composite bullet belt and welding method technology, which is applied in welding equipment, welding/welding/cutting items, ammunition, etc., can solve the problems affecting the life of the gun body, the range of the shell, the wear of the soft iron belt rifling, and the limitation of the belt, etc., to achieve Avoid pan-iron and pan-carbon phenomena, prolong rifling life, and increase the effect of gas-holding degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

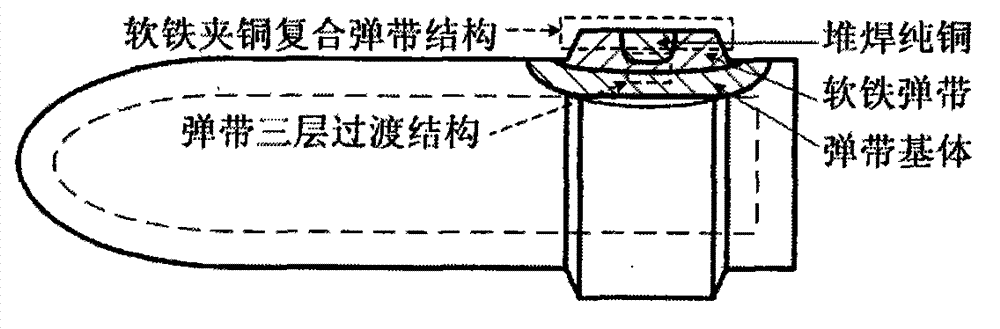

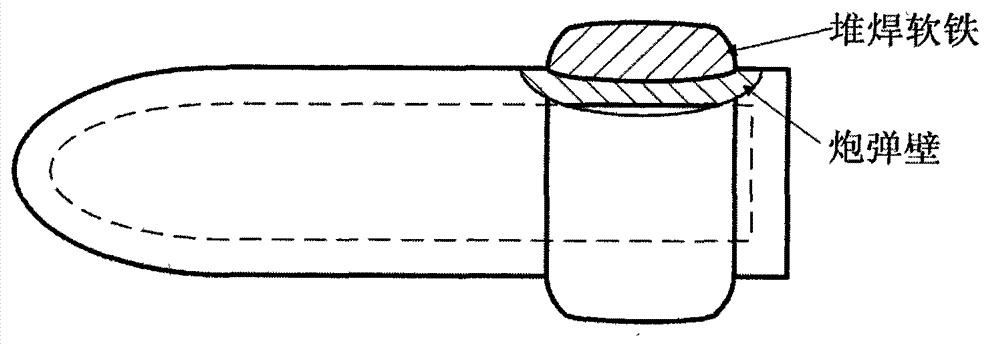

[0024] combine figure 1 , the present invention adopts two kinds of materials to surfacing to form elastic bands on the surface of the projectile, wherein the soft iron elastic bands are located on both sides of the elastic bands, and the pure copper elastic bands are located in the middle, forming a structure in which soft iron fully wraps pure copper.

[0025] In the welding method of the present invention, when surfacing the elastic belt on the surface of the projectile, the soft iron part is first welded, and the soft iron elastic belt is cut and grooved, and then the pure copper part is surfacing welded in the groove opened, and finally the second step is carried out. The secondary cutting process finally forms a complete elastic belt that meets the design requirements. The ratio of the copper elastic belt and the soft iron elastic belt in the composite elastic belt can be flexibly adjusted in the entire elastic belt structure, thereby adjusting the strength of the elastic...

Embodiment 2

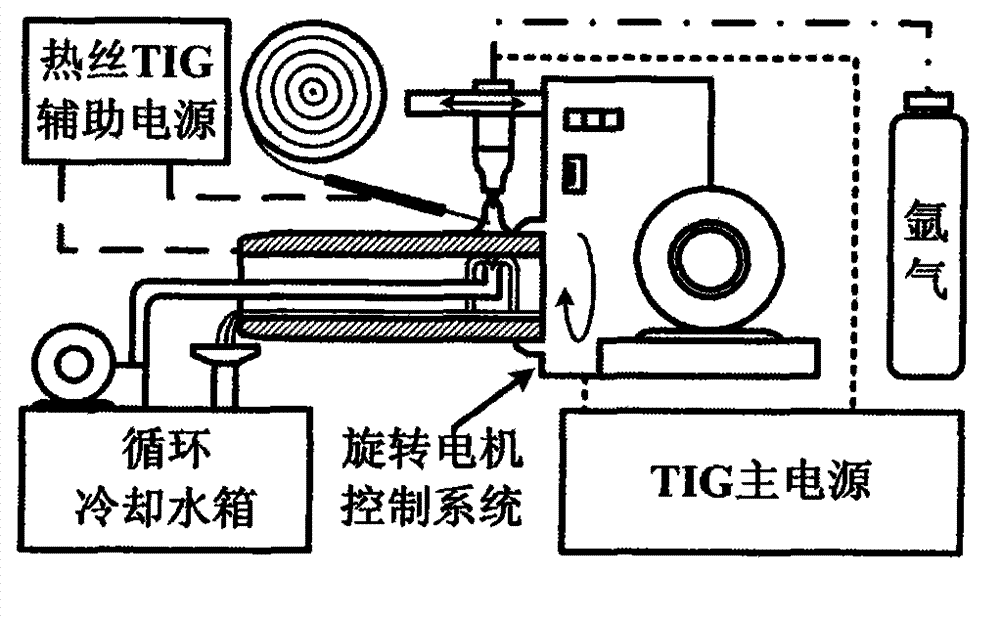

[0027] Such as figure 1 As shown, the welding belt structure proposed by the present invention is suitable for the belt manufacturing process of shells with a diameter of 30-100mm. The welding method selected, hot wire TIG, promptly adopts tungsten argon arc welding, and the arc hot wire is semi-automatically fed The way to weld the elastic belt.

[0028] Such as figure 2 As shown, the two electrodes of the secondary TIG power supply are respectively connected to the wire feeder and the workpiece to form a conductive circuit. At the beginning of the welding process, connect the main welding circuit, ignite the main arc to preheat the workpiece for 1-2 seconds, then feed the welding wire through the wire feeding device, and connect the hot wire circuit when the end of the welding wire is 5-8mm away from the workpiece. The size of the belt is designed according to the diameter of the gun body and the function of the shell, and the welding process is carried out. During the w...

Embodiment 3

[0032] At the same time, in the welding process, if the proportion of copper and soft iron is different, elastic belts with different properties can be obtained. After the processing is completed, cut the elastic band longitudinally to expose the cross section. When the cross-sectional area of the pure copper elastic band and the soft iron cross-sectional area are 1:1, the welding process parameters will be changed accordingly. In this case, the soft iron elastic band will be welded Some welding parameters do not need to be changed. The output current of the main TIG power supply is 250A, the auxiliary current is 40-60A, the auxiliary voltage is about 13-15V, the wire feeding speed is 2-3m / min, and the rotation period of the projectile is 100s. After one week, the surfacing welding of the soft iron is completed to ensure a certain penetration depth of the soft iron on the projectile body. Due to the high content of pure copper in the elastic band, and the current is relative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com