Continuous grinding method for brominated flame retardant and grinding machine for realizing method

A technology of brominated flame retardants and grinding methods, which is applied in the field of grinding machines, can solve problems such as equipment corrosion, increase product production costs, and long grinding time, so as to avoid the impact of product quality, reduce the impact of product quality, and reduce particle size. The effect of small diameter distribution range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

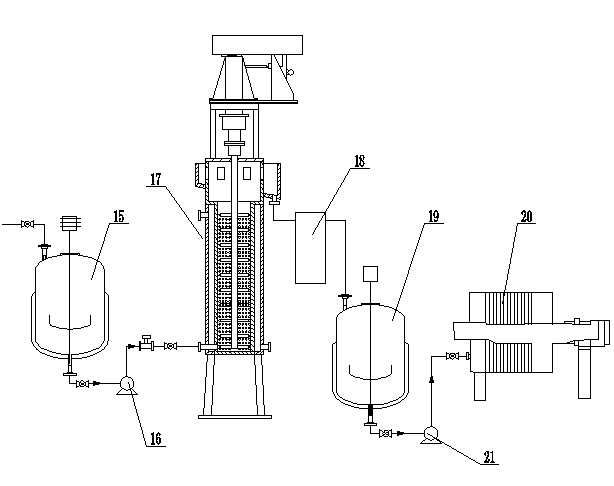

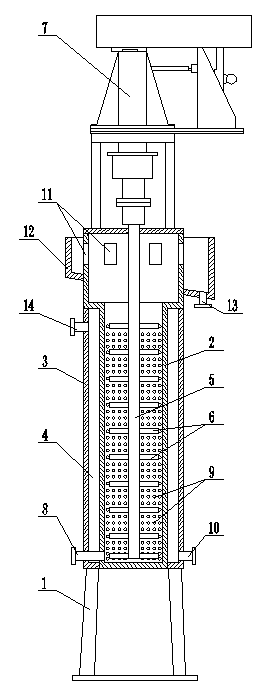

[0031] According to the mass ratio relationship of decabromodiphenylethane: sodium sulfite: sodium carbonate: process water=1000:5:5:500, the above-mentioned materials are added into the mixer 15 and mixed to obtain a mixed material liquid; 16. The mixed material liquid is continuously fed into the grinder from the bottom of the grinder 17 for grinding; the feeding speed is controlled so that the mixed material liquid that enters the grinder later pushes the mixed material liquid that enters first to move upwards and the bottom layer It takes 4 hours for the mixed material liquid to flow out from the overflow port on the top of the grinder. In other words, it takes 4 hours for the mixed material liquid to flow out from the overflow port after entering the bottom of the inner cavity of the grinder. machine, the overflow feed liquid also continuously flows out from the overflow port; the overflow feed liquid flows through the iron remover 18 to remove ferromagnetic substances, th...

Embodiment 2

[0033] According to the mass ratio relationship of decabromodiphenylethane: hydrazine hydrate: sodium bicarbonate: process water=1000:5:10:1000, the above-mentioned materials are added into the mixer 15 and mixed to obtain a mixed material liquid; The feeding pump 16 continuously feeds the mixed material liquid from the bottom of the grinder into the grinder for grinding; the feeding speed is controlled so that the mixed material liquid that enters the grinder last pushes the mixed material liquid that entered first to move upwards and the bottom layer The mixed material liquid flows out from the overflow port on the top of the grinder after 0.6 hours. Grinding machine, the overflow material liquid also continuously flows out from the overflow port; the overflow material liquid flows through the iron remover 18 to remove ferromagnetic substances, then enters the buffer tank 19, and then is sent from the buffer tank 19 by the feed pump 21 Enter the filter press 20 to carry out ...

Embodiment 3

[0035] According to the mass ratio relationship of decabromodiphenyl ether: thiourea dioxide: potassium carbonate: process water=1000:15:10:2000, the above-mentioned materials are added into the mixer 15 and mixed to obtain a mixed material liquid; 16 Feed the mixed material liquid from the bottom of the grinder continuously into the grinder for grinding; control the feeding speed so that the mixed material liquid that enters the grinder later pushes the mixed material liquid that enters first to move upwards and makes the bottom layer of the mixed material liquid It takes 0.2 hours for the material liquid to flow out from the overflow port on the top of the grinder. In other words, it takes 0.2 hours for the mixed material liquid to flow out from the overflow port after entering the bottom of the inner cavity of the grinder. Because the mixed material liquid continuously enters the grinder , the overflow feed liquid also continuously flows out from the overflow port; the overf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com