High-sensitivity solid-state color image sensor

A color image, high-sensitivity technology, applied in the direction of radiation control devices, etc., can solve the problems of reducing detection accuracy, affecting detection sensitivity and dynamic range, and achieve the effect of mature technology, improved sensitivity and dynamic range, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

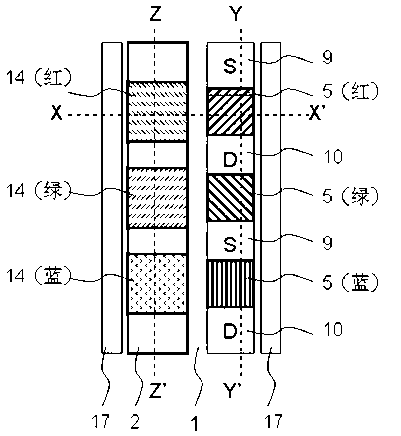

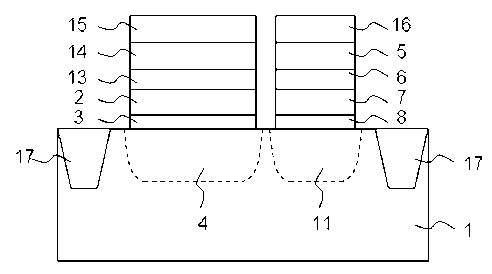

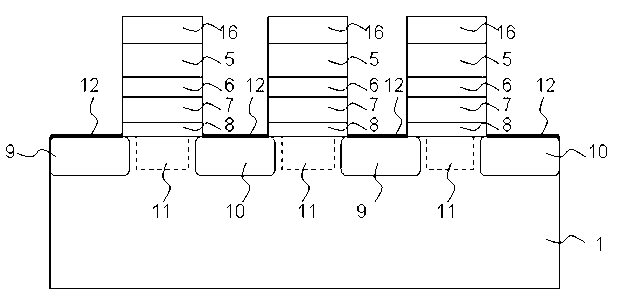

[0021] (1) Color image sensor structure

[0022] The top and cross-sectional schematic diagrams of the color image sensor pixel unit are shown in Figure 1 ~ Figure 4 shown. Each red, green, and blue pixel sub-unit is composed of a MOS capacitor and a MOSFET structure storage tube respectively. The P-type silicon substrate material 1 Accumulation gate with large area above 2 , an insulating dielectric layer is provided between the accumulation gate and the P-type silicon substrate 3 , the accumulation gate-insulating dielectric layer-P-type semiconductor silicon substrate forms a MOS capacitor, and the silicon substrate under the accumulation gate is the photoelectric conversion region 4 . Next to the accumulation gate is a control gate perpendicular to the accumulation gate 5 . A blocking insulating dielectric layer is sequentially arranged directly below the control grid 6 , Optoelectronic storage layer 7 , tunnel oxide 8 and P-type semiconductor silicon substrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com