A wafer-level through-silicon transmission structure applicable to microwave frequency bands and its manufacturing method

A technology of microwave frequency band and transmission structure, applied in semiconductor/solid-state device manufacturing, waveguide, waveguide-type devices, etc., can solve the problems of lithography capability and lithography precision limitation, coaxial line difficulties, etc., and achieve small mechanical and physical damage , Guaranteed precision and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

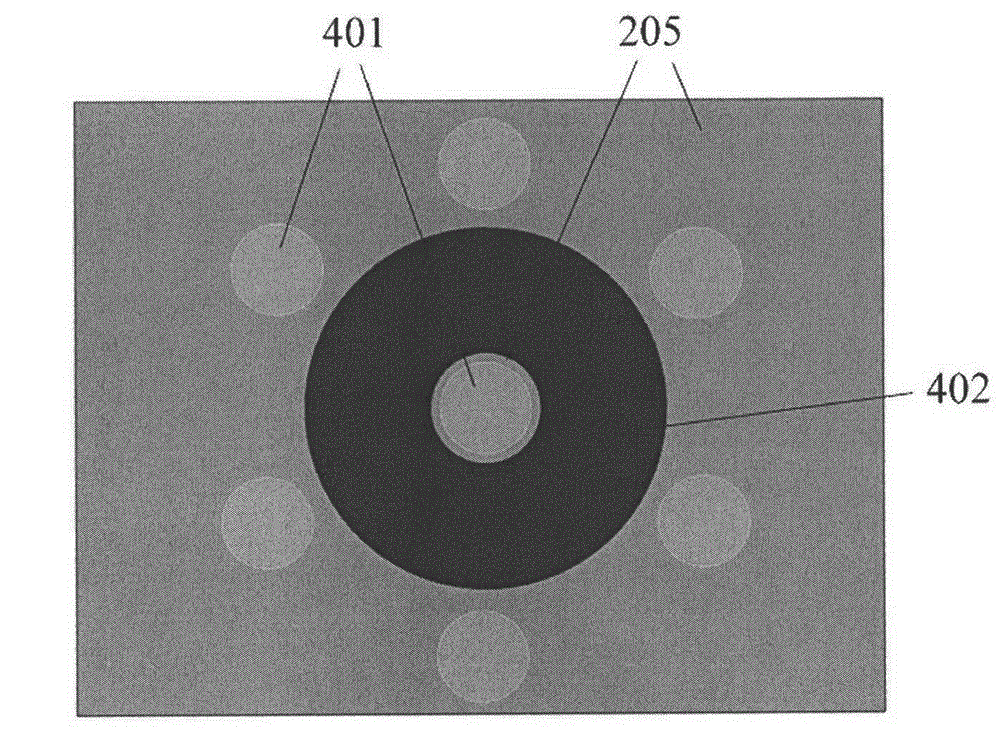

[0027] exist Figure 2-1-Figure 2-10 In , the process flow of the wafer-level through-silicon transmission structure applied in the microwave frequency band is introduced in detail.

[0028] 1. Surface pretreatment of silicon wafer 101, growth of oxide layer 102, such as diagram 2-1 shown.

[0029] a) performing surface pretreatment on both sides of the silicon wafer 101;

[0030] b) growing an oxide layer 102 as a mask.

[0031] 2. Form the through hole etching window 103, such as Figure 2-2 shown.

[0032] a) Forming a through-hole etching window 103 on the front surface of the silicon wafer 101 by photolithography, development and etching.

[0033] 3. Form blind holes (holes that are not pierced) 104, such as Figure 2-3 shown.

[0034] a) Form a vertical silicon blind hole 104 with a depth of half the thickness of the silicon wafer (for example, about 225 μm) on the front surface of the silicon wafer 101 by deep reactive ion etching (DRIE) process.

[0035] 4. Fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com