Ultrasonic-assisted grapheme photoresist removing method

An ultrasonic and graphene technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of graphene damage, incomplete deglue, and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

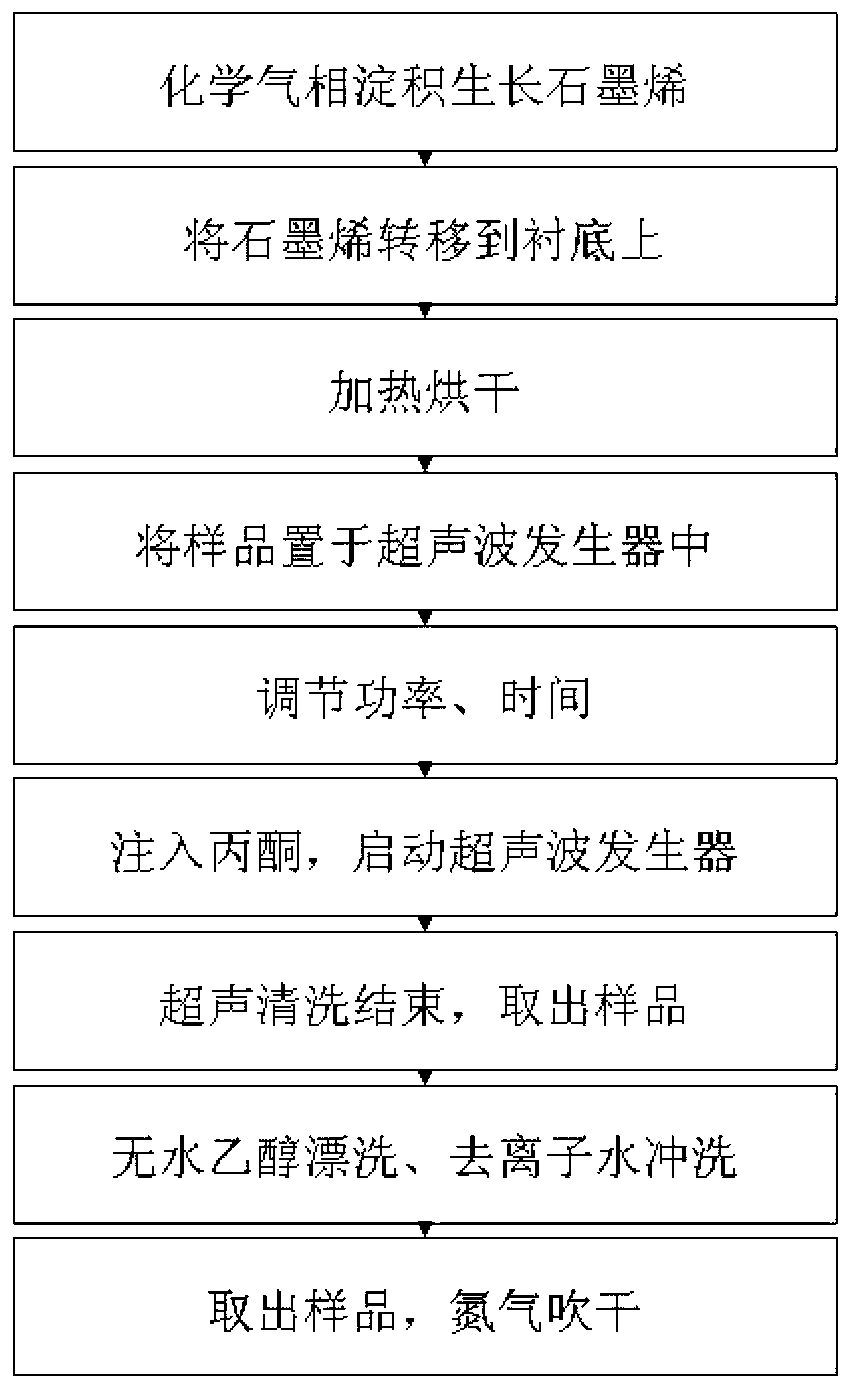

[0050] (1) The graphene grown on the copper foil by the chemical vapor deposition method is glued and dried with PMMA;

[0051] (2) with FeCl 3 The solution corrodes the lower copper foil;

[0052] (3) Transfer of PMMA-shaped graphene to Si-SiO 2 on the substrate;

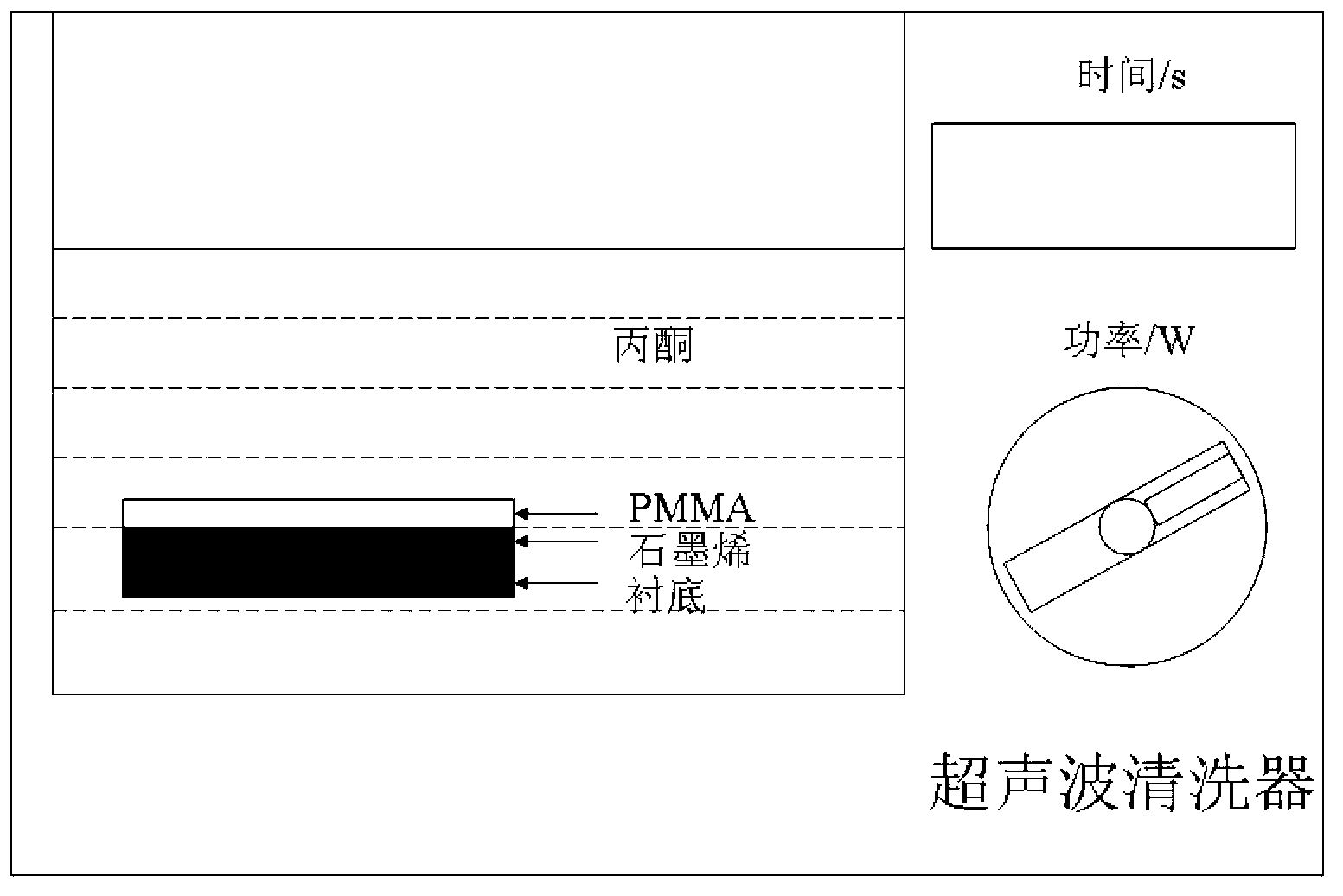

[0053] (4) Put the graphene sample into the ultrasonic generator, adjust the power to 10W, and the time is 2min;

[0054] (5) Inject analytically pure acetone and start the ultrasonic generator for cleaning;

[0055] (6) After cleaning, take out the sample, rinse it in absolute ethanol for 2 minutes, and then rinse it with deionized water for 2 minutes;

[0056] (7) Blow dry the samples with nitrogen for storage.

Embodiment 2

[0058] (1) The graphene grown on the copper foil by the chemical vapor deposition method is glued and dried with PMMA;

[0059] (2) with FeCl 3 The solution corrodes the lower copper foil;

[0060] (3) Transfer of PMMA-shaped graphene to Si-SiO 2 on the substrate;

[0061] (4) Put the graphene sample into the ultrasonic generator, adjust the power to 300W, and the time is 10min;

[0062] (5) Inject analytically pure acetone and start the ultrasonic generator for cleaning;

[0063] (6) After cleaning, take out the sample, rinse it in absolute ethanol for 20 minutes, and then rinse it with deionized water for 20 minutes;

[0064] (7) Blow dry the samples with nitrogen for storage.

Embodiment 3

[0066] (1) The graphene grown on the copper foil by the chemical vapor deposition method is glued and dried with PMMA;

[0067] (2) with FeCl 3 The solution corrodes the lower copper foil;

[0068] (3) Transfer of PMMA-shaped graphene to Si-SiO 2 on the substrate;

[0069] (4) Put the graphene sample into the ultrasonic generator, adjust the power to 60W, and the time is 6min;

[0070] (5) Inject analytically pure acetone and start the ultrasonic generator for cleaning;

[0071] (6) After cleaning, take out the sample, rinse it in absolute ethanol for 10 minutes, and then rinse it with deionized water for 10 minutes;

[0072] (7) Blow dry the samples with nitrogen for storage.

[0073] The invention discloses an ultrasonic-assisted degumming method for cleaning graphene, which mainly solves the problems of incomplete degumming, easy damage to graphene and low efficiency in the prior art. It includes the following steps: (1) use PMMA to spray and dry the graphene grown on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com