Punching injection type fractured stone material mining and processing method

A technology of glue injection and stone material, which is applied in earth square drilling, open-pit mining, special mining, etc. It can solve the problems of low yield rate and difficult mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

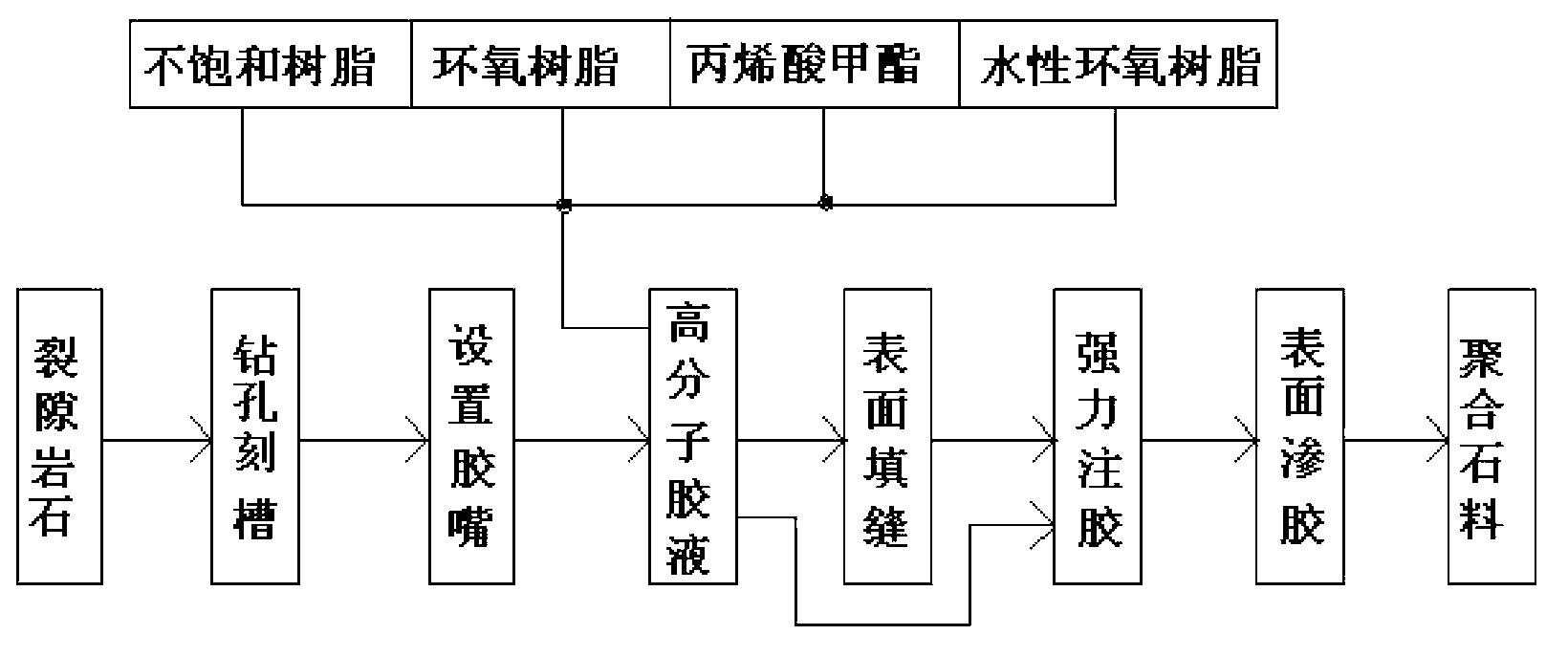

[0019] Such as figure 1 As shown, for the mines in arid areas such as Dunhuang jade and tremolite in Guazhou County, Gansu Province, the drilling and injection method is used to simultaneously carry out the block mining of injection polymerization and high-pressure expansion cracking. The process steps are as follows:

[0020] 1. The process of drilling and grooving is to use a rock drill and a 40mm drill bit to mine cuboid blocks on three mutually perpendicular cracking surfaces, and drill them in a straight line with a distance of 20-100cm and deep holes of 100-300cm. Three rows of deep holes, and then use the groove tool (Hubei Building Materials Research Institute Luo Zuchun) to make grooves with a sharp angle of 60 degrees and a depth of 8mm, so that the deep holes become approximately diamond-shaped and increase the compression area;

[0021] 2. The process of setting the glue injection nozzle is to use 3 high-pressure glue injection devices (Beijing Lioud Crack Treatmen...

Embodiment 2

[0027] For granite and serpentinized marble, cuboid stones used for carving columns and Buddha statues. The process steps for strong penetration and strengthening are:

[0028] 1. The drilling process is to use a thin-walled drill to drill a deep hole with a diameter of 80 mm and a depth smaller than the length of the material body along the center of the length direction;

[0029] 2. The process of setting the glue injection nozzle is to pre-embed the glue injection nozzle in the orifice with structural glue for stone, and use a high-pressure rubber hose to communicate with a high-pressure glue injection device;

[0030]3. The polymer glue preparation process is to use Yabang 7936 unsaturated resin, OT curing agent, KH570 silane coupling agent and styrene in a mass ratio of 100:2:2:80 to form a single-component glue with a viscosity of 100cps. liquid;

[0031] 4. The surface filling process is to fill the gaps on the surface of the stone with a width of more than 0.1mm with...

Embodiment 3

[0035] For minerals with obvious cracks such as stromatolites, quartzites, and tremolites, the process of expanding and cracking along the cracks is as follows:

[0036] 1. The drilling and grooving process is to drill holes with a distance of 80cm along the vertical plane of the cracks in the ore body with a width of more than 0.5mm and a sharp angle of 50° for two rows of deep holes arranged vertically. And the groove with a depth of 10mm makes the round hole form an approximate diamond shape, and the deep hole and the sharp corner of the groove are arranged in a straight line;

[0037] 2. The process of setting the injection nozzle is to configure the injection nozzle with a valve and a funnel, insert a 500W resistance wire heating device into each deep hole, use two insulated wires to lead out along the gap between the nozzle and the round hole, and use structural glue sticky;

[0038] 3. The polymer glue configuration process is to use methyl methacrylate, organic peroxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com