Method for repairing and strengthening gear through laser compound microtexture

A laser shock-strengthening and micro-texturing technology, applied in the field of laser composite micro-texture repairing and strengthening gears, can solve the problems of reduced gear tooth thickness, high cost, transmission failure, etc., and achieve uniform thickness, uniform steps, and uniform hardness distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

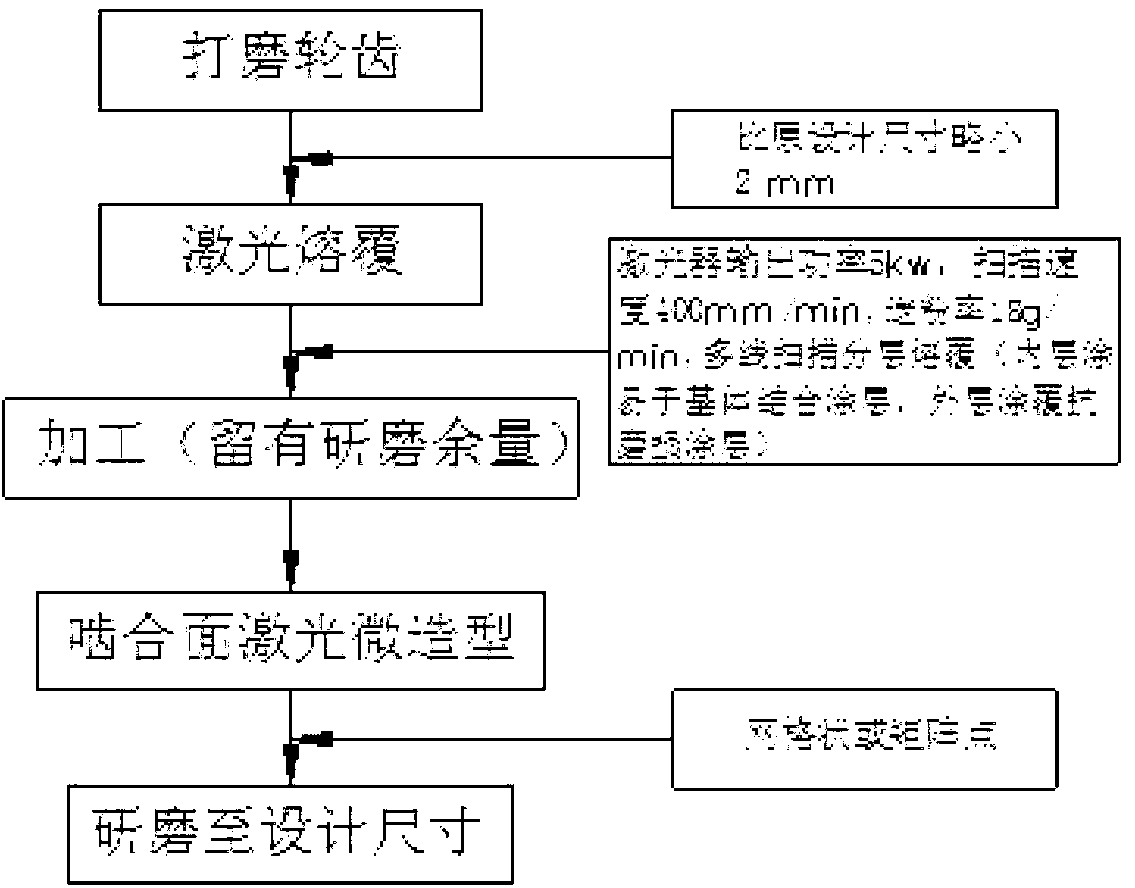

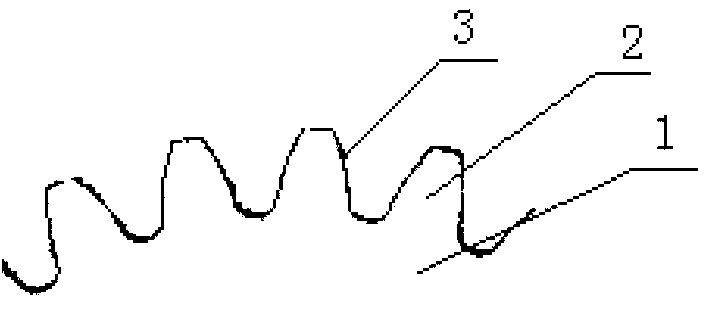

[0023] like Figure 1-2 As shown, the present invention provides a method for repairing and strengthening gears with laser composite microtexture, comprising the following steps:

[0024] (1) Carry out laser coating modeling treatment on the meshing surface of gear parts; specifically, include:

[0025] (1.1) Grind the meshing surface of the worn gear body 1 again with a grinder, and the thickness of the gear tooth 2 is required to be reduced by about 2mm compared to the original design value;

[0026] (1.2) Using the laser coating method, make a nickel-based wear-resistant alloy powder coating layer 3 on the surface of the polished gear; the output power of the laser is 5kw, the scanning speed is 400mm / min, the powder feeding rate is 18g / min, and the melting rate is 18g / min. The thickness of the cladding is 1.5-2mm, and multiple cladding can be carried out; and a grinding allowance is reserved.

[0027] (1.3) The working surface after laser coating is processed close to its...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com