Method for growing p-type transparent and conducting Ni1-xMgxO crystal film by doping Li

A transparent conductive, crystal technology, applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problems that it is difficult to meet the requirements of optoelectronic device applications, there are few types of p-type TCO thin film materials, and poor photoelectric performance , to achieve the effect of excellent crystal quality, low resistivity and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

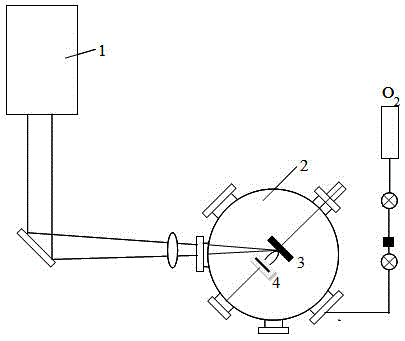

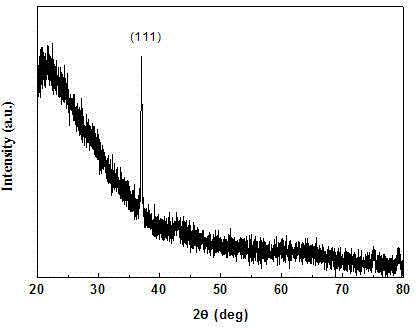

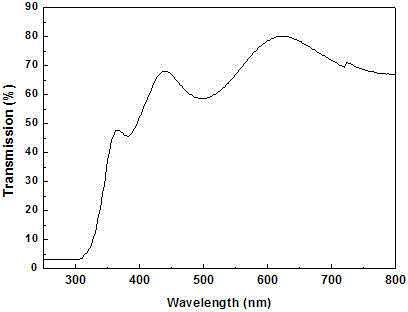

Method used

Image

Examples

Embodiment 1

[0024] 1) Weigh NiO, MgO and Li with a purity of 99.99% 2 CO 3 Powder, wherein the molar percentage content x of MgO is 20%, the molar percentage content y of Li is 4%, NiO, MgO and Li 2 CO 3 The mixed powder and an appropriate amount of ethanol are poured into a ball mill jar equipped with agate balls successively, and placed on a ball mill for ball milling for 24 hours. There are two purposes of ball milling: on the one hand, it is to make NiO, MgO and Li 2 CO 3 The powder is mixed evenly to ensure the uniformity of the target material composition; on the other hand, it is to mix NiO, MgO and Li 2 CO 3 The powder is refined to facilitate the subsequent molding and sintering of the mixed powder.

[0025] After ball milling, the raw materials are separated and dried, and the resulting powder is ground and pressed into shape. Put the formed green body into a sintering furnace, pre-sinter at 800 °C for 1 hour, and then sinter at 1100–1200 °C for more than 4 hours to obtai...

Embodiment 2

[0029] 1) Weigh NiO, MgO and Li with a purity of 99.99% 2 CO 3 Powder, wherein the molar percentage content x of MgO is 30%, the molar percentage content y of Li is 8%, NiO, MgO and Li 2CO 3 The mixed powder and an appropriate amount of ethanol are poured into a ball mill jar equipped with agate balls successively, and placed on a ball mill for ball milling for 24 hours. There are two purposes of ball milling: on the one hand, it is to make NiO, MgO and Li 2 CO 3 The powder is mixed evenly to ensure the uniformity of the target material composition; on the other hand, it is to mix NiO, MgO and Li 2 CO 3 The powder is refined to facilitate the subsequent molding and sintering of the mixed powder.

[0030] After ball milling, the raw materials are separated and dried, and the resulting powder is ground and pressed into shape. Put the formed green body into a sintering furnace, pre-sinter at 800 °C for 1 hour, and then sinter at 1100–1200 °C for more than 4 hours to obtain...

Embodiment 3

[0034] 1) Weigh NiO, MgO and Li with a purity of 99.99% 2 CO 3 Powder, wherein the molar percentage content x of MgO is 10%, the molar percentage content y of Li is 4%, NiO, MgO and Li 2 CO 3 The mixed powder and an appropriate amount of ethanol are poured into a ball mill jar equipped with agate balls successively, and placed on a ball mill for ball milling for 24 hours. There are two purposes of ball milling: on the one hand, it is to make NiO, MgO and Li 2 CO 3 The powder is mixed evenly to ensure the uniformity of the target material composition; on the other hand, it is to mix NiO, MgO and Li 2 CO 3 The powder is refined to facilitate the subsequent molding and sintering of the mixed powder.

[0035] After ball milling, the raw materials are separated and dried, and the resulting powder is ground and pressed into shape. Put the shaped green body into a sintering furnace, pre-sinter at 800 °C for 1 hour, and then sinter at 1100-1200 °C for more than 4 hours to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice constant | aaaaa | aaaaa |

| lattice constant | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com