An electromagnetic induction desulfurization iron ladle

A technology of electromagnetic induction and molten iron tank, which can be used in casting molten material containers, manufacturing tools, metal processing equipment, etc., and can solve problems such as low efficiency and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail with the accompanying drawings and specific embodiments.

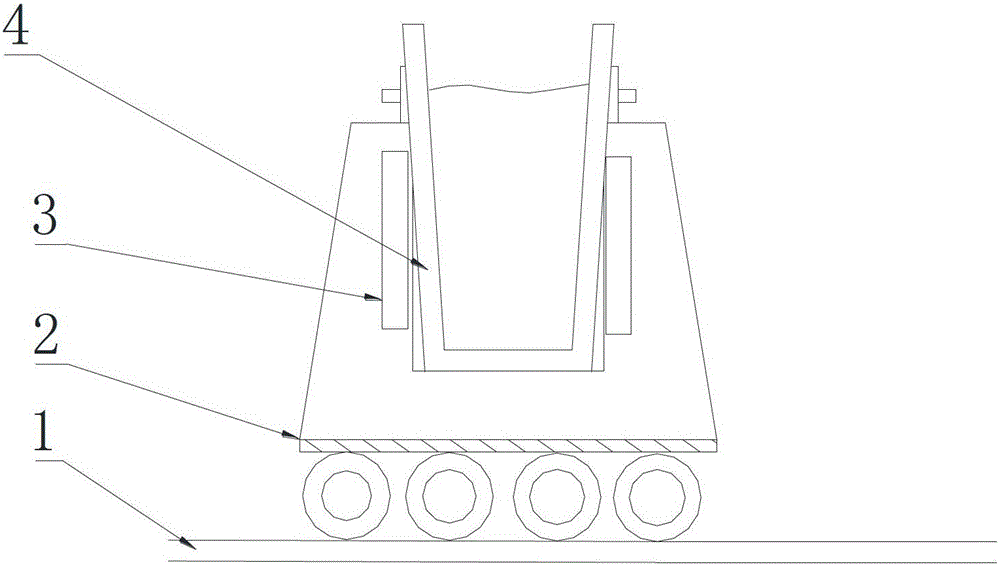

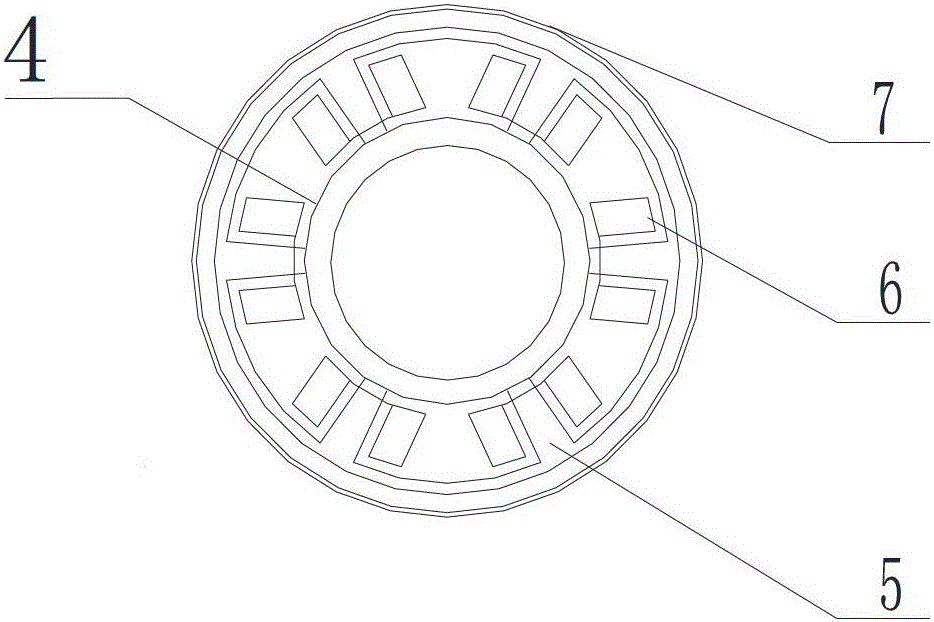

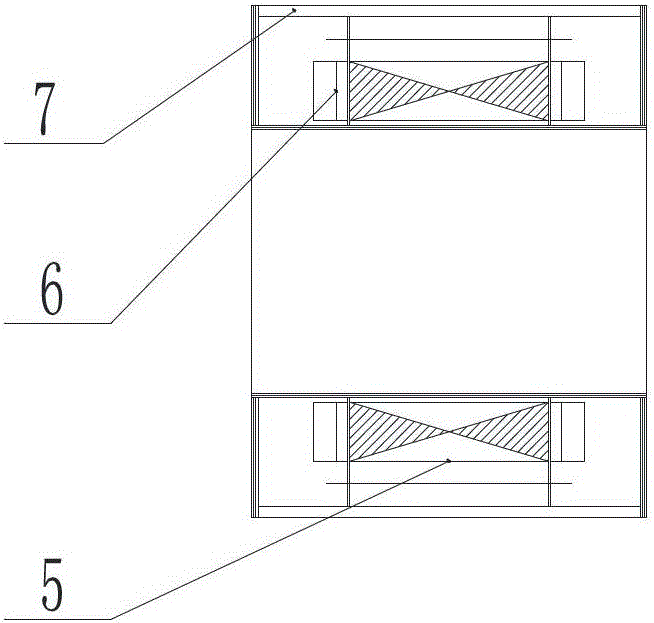

[0018] Such as figure 1 As shown, an electromagnetic induction desulfurization molten iron tank, a trolley 2 is placed on the guide rail 1, a molten iron tank 4 is installed on the trolley 2, and an electromagnetic induction stirring device 3 is installed on the outer wall of the molten iron tank 4 in a ring shape. Such as figure 2 with image 3 As shown, the electromagnetic induction stirring device 3 includes a shielding shell 7 and six sets of iron cores 5, a coil 6 is wound on any set of iron cores 5, and the shielding shell 7 covers the six sets of iron cores 5 and the coils 6 wound thereon. Inside

[0019] When the trolley 2 transports the molten iron through the guide rail 1, the low-frequency two-phase current is supplied to the coil 6, accompanied by a changing electromagnetic field, which forms a thrust when passing through the molten steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com