Fermentation technique of A40926

A fermentation process and fermentation tank technology, applied in the biological field, can solve the problems of low fermentation yield and failure to meet production requirements, and achieve the effects of high fermentation level, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

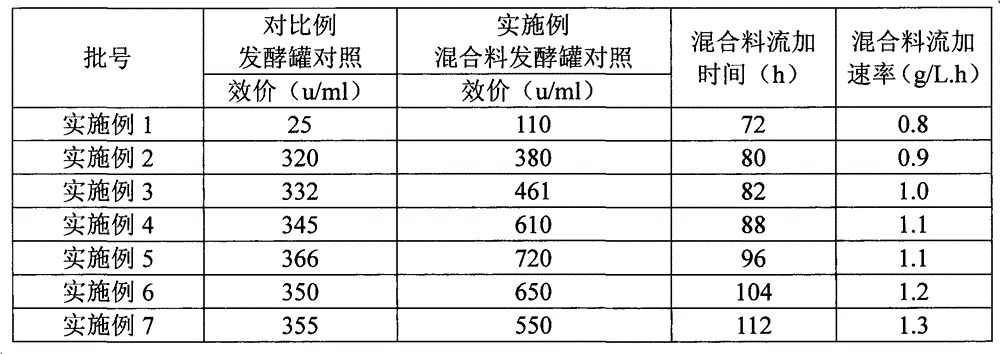

Examples

Embodiment 1

[0022] Inoculate the Nonomuraea genus Actinomycetes ATCC 39727 (Nonomuraea.sp ATCC 39727) stored on the slant plate into the primary seed medium of the shake flask: beef extract 0.3%, casein 0.5%, oat flour 3%, calcium carbonate 0.4%, pH 7.0, cultured at 30°C for 72h, shaker speed 240rpm; 5% inoculum amount was inserted into the secondary seed medium (the same level seed medium) of the shake flask, and cultured on a rotary shaker at 28°C for 72h , Shaker speed 240rpm.

[0023] Afterwards, according to the 8% inoculum amount, inoculate in a 50L fermenter for fermentation, the actual liquid volume is 28L, and cultivate at 26°C for 226h. Wherein, the stirring speed is 200 rpm, the tank pressure is 0.02 MPa, and the ventilation ratio is 1:1 V / V·min.

[0024] Fermentation medium is prepared according to conventional methods, and comprises glucose 4.5% in every liter, ammonium sulfate 0.83%, potassium dihydrogen phosphate 0.15%, magnesium sulfate heptahydrate 0.1%, yeast extract 0....

Embodiment 2

[0028] Inoculate the Nonomuraea genus Actinomycetes ATCC 39727 (Nonomuraea.sp ATCC 39727) preserved on the slant plate into the primary seed medium of the shake flask: beef extract 0.4%, casein 0.2%, oat flour 2%, calcium carbonate 0.2%, pH 7.0, cultured at 30°C for 75h, shaker speed 240rpm; 5% inoculum size was inserted into the shake flask secondary seed medium (seed medium of the same level), and cultivated at 28°C for 72h on a rotary shaker , Shaker speed 240rpm.

[0029] Afterwards, according to the 6% inoculum amount, inoculate in a 50L fermenter for fermentation, the actual liquid volume is 28L, and cultivate at 28°C for 215h. Wherein, the stirring speed is 240rpm, the tank pressure is 0.03MPa, and the ventilation ratio is 1:1.2V / V·min.

[0030] The fermentation medium is prepared according to conventional methods, and each liter contains 3% corn starch, 0.5% glucose, 1% sucrose, 3% soybean cake powder, 1.5% fish meal peptone, 0.4% casein, 0.1% L-valine, carbonic acid ...

Embodiment 3

[0033] Inoculate the Nonomuraea genus Actinomycetes ATCC 39727 (Nonomuraea.sp ATCC 39727) preserved on the slant plate into the primary seed medium of the shake flask: 0.5% beef extract, 0.5% casein, 4% oat flour, calcium carbonate 0.5%, pH 7.0, cultured at 30°C for 75h, shaker speed 240rpm; 5% inoculum was inserted into the shake flask secondary seed medium (seed medium of the same level), and cultivated at 28°C for 72h on a rotary shaker , Shaker speed 240rpm.

[0034] According to the 8% inoculum amount, it is inoculated in a 50L fermenter for fermentation, and the actual liquid volume is 28L. Incubate at 27°C for 218h. The stirring speed is 250rpm, the tank pressure is 0.05MPaMPa, and the ventilation ratio is 1:1V / V·min

[0035] The fermentation medium is prepared according to conventional methods, and each liter contains 5% corn starch, 0.75% glucose, 1.5% sucrose, 3.5% soybean cake powder, 1.25% fish meal peptone, 0.45% casein, 0.11% L-valine, carbonic acid Calcium 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com