Low-corrosion complex chloride snow-melting agent

A snow-melting agent and low-corrosion technology, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of unstable composition performance, high sodium ion content, high corrosion of carbon steel, etc., and achieve high cost performance and easy availability of raw materials , reduce the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

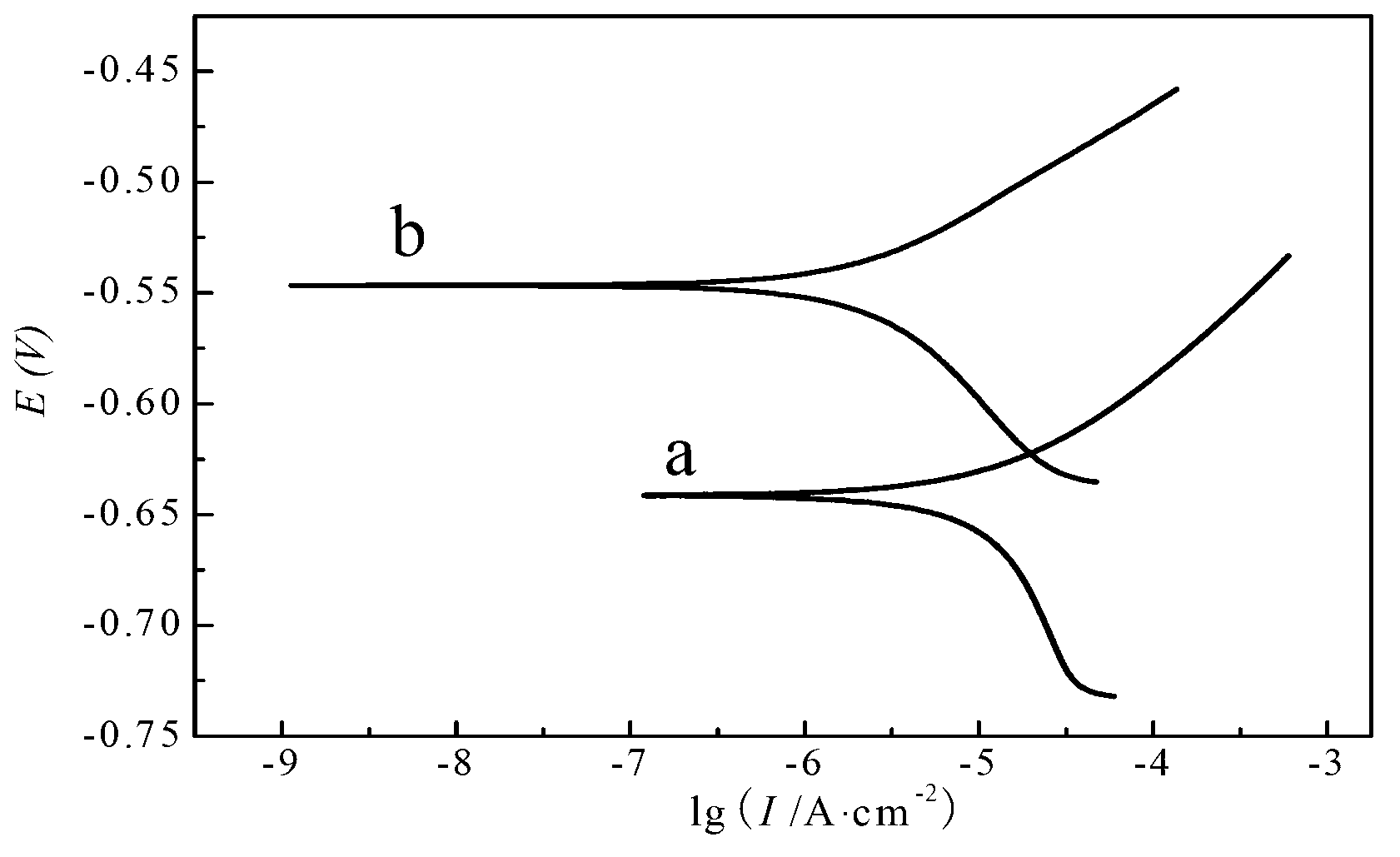

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Take the preparation of 100g of low-corrosion composite chlorine salt deicing agent as an example, which contains the following raw materials in proportions by mass:

[0036]

[0037] The number average molecular weight of the said polyethylene glycol is 2000-10000.

[0038] The preparation method of above-mentioned deicing agent is made up of the following steps:

[0039] (1) Mix calcium chloride dihydrate and magnesium chloride hexahydrate according to the above mass ratio, mechanically pulverize, and pass through a 50-mesh sieve to obtain a mixture of calcium and magnesium chloride salts.

[0040] (2) Mix other raw materials according to the above-mentioned ratio of parts by mass, stir evenly, and pass through a 100-mesh sieve to obtain an additive mixture.

[0041] (3) Put the mixture of calcium and magnesium chloride salts in step (1) and the additive mixture in step (2) into a mixer and stir evenly, dry at high temperature, granulate into a particle size of 5 ...

Embodiment 2

[0043] Take the preparation of 100g of low-corrosion composite chlorine salt deicing agent as an example, which contains the following raw materials in proportions by mass:

[0044]

[0045] Its preparation method is identical with embodiment 1.

Embodiment 3

[0047] Take the preparation of 100g of low-corrosion composite chlorine salt deicing agent as an example, which contains the following raw materials in proportions by mass:

[0048]

[0049] Its preparation method is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com