Bonding glue used for glass mosaics and preparation method thereof

A glass mosaic and adhesive technology, applied in the field of adhesive, can solve the problems of reduced degree of polymerization, smaller molecular weight, insufficient adhesive force and water resistance of adhesive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

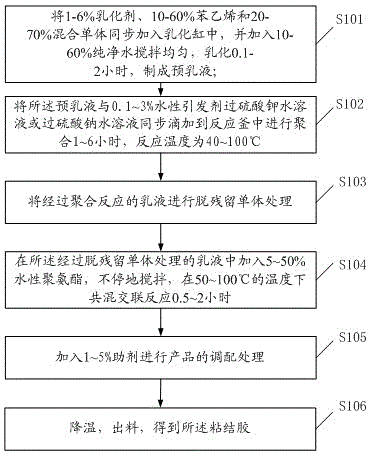

[0142] Correspondingly, an embodiment of the present invention also provides a method for preparing an adhesive for glass mosaics, including:

[0143] S101, add 1-6% emulsifier, 10-60% styrene and 20-70% mixed monomer into the emulsification tank simultaneously, add 10-60% pure water and stir evenly, emulsify for 0.1-2 hours, and make pre- Lotion;

[0144] Preferably, the time of the emulsification reaction is 0.5-1 hour.

[0145] Wherein, the emulsifier is an emulsion made of vinyl alkylphenol polyoxyethylene ether sodium sulfate and anion.

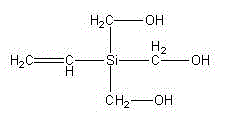

[0146] The mixed monomers include acrylate, hydroxyethyl acrylate, acrylic acid and vinyltrimethoxysilane;

[0147] Preferably, the mixed monomers include:

[0148] Acrylate 20~60%

[0149] Hydroxyethyl Acrylate 0.5~5%

[0150] Acrylic acid 0.5~5%

[0151] Vinyltrimethoxysilane 1~10%;

[0152] The acrylate is butyl acrylate and / or octyl acrylate and / or methyl methacrylate.

[0153] In addition, in the above-mentioned emulsificati...

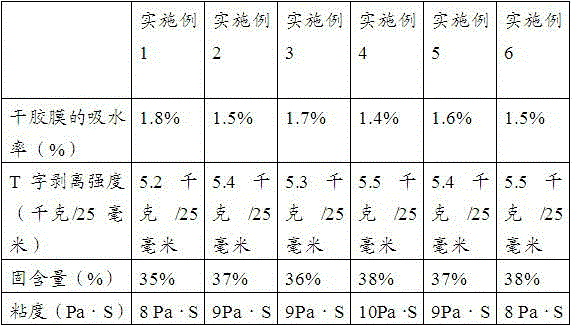

Embodiment 1

[0188] Add the emulsion made of 1% vinyl alkylphenol polyoxyethylene ether sodium sulfate and anion, 10% styrene and 20% acrylate into the emulsification tank simultaneously, add 30% pure water and stir evenly, and emulsify for 0.1 hour to prepare pre-emulsion;

[0189] The pre-emulsion and 0.1% aqueous initiator potassium persulfate aqueous solution were synchronously dropped into the reactor for polymerization for 1 hour, and the reaction temperature was 40°C;

[0190] Add 0.1% peroxide initiator di-tert-butyl peroxide to denucleate the residual monomer;

[0191] Add reducing agent sodium formaldehyde thiosulfate to decompose unreacted peroxide initiator di-tert-butyl peroxide;

[0192] Vacuum;

[0193] Add 37.8% water-based polyurethane to the emulsion that has been treated with residual monomers, stir continuously, and blend and crosslink for 0.5 hours at a temperature of 50°C;

[0194] Add 1% defoamer emulsified silicone oil for product preparation;

[0195] Lower the...

Embodiment 2

[0197] Emulsion of 1% vinyl alkylphenol polyoxyethylene ether sodium sulfate and anion, 30% styrene and 25% acrylate, 0.5% hydroxyethyl acrylate, 0.5% acrylic acid and 4% vinyltrimethoxysilane Simultaneously add to the emulsification tank, add 30% pure water and stir evenly, emulsify for 1 hour to make a pre-emulsion;

[0198] The pre-emulsion and 1% aqueous initiator sodium persulfate aqueous solution were synchronously added dropwise to the reactor for 3 hours of polymerization, and the reaction temperature was 70°C;

[0199] Add 1% peroxide initiator benzoyl peroxide to denucleate the residual monomers;

[0200] Add reducing agent sodium sulfite to decompose unreacted peroxide initiator benzoyl peroxide;

[0201] Vacuum;

[0202] Add 5% water-based polyurethane to the emulsion treated by removing residual monomers, stir continuously, and blend and cross-link for 1 hour at a temperature of 70°C;

[0203] Add 1% defoamer emulsified mineral oil, 1% thickener polyacrylic aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com