Polylactic acid-plant fiber composite degradable material

A plant fiber and polylactic acid technology, which is applied in the field of polylactic acid plant fiber composite materials, can solve problems such as environmental pollution, air pollution, human and ecological environment hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Please refer to Fig. 1, which is a schematic diagram of the manufacturing process of a polylactic acid plant fiber composite decomposable material according to the present invention. into, its manufacture method is as follows:

[0039] a. The polymer starch 11 is catalyzed by a catalyst 12 at high speed and high temperature to change its molecular weight into plasticity, and has a polylactic acid masterbatch 10 that can be stretched in four directions;

[0040] b. Use agricultural waste (such as corn stalks, cotton stalks, millet stalks) or waste left over from agricultural processing (such as rice husks, cassava flour), and grind them into the required particle size and mesh at a high speed by cooling the physical principle Plant fiber powder 21, then carry out high-temperature sterilization and emulsification polymerization with starch 22 to make plant fiber filler 20;

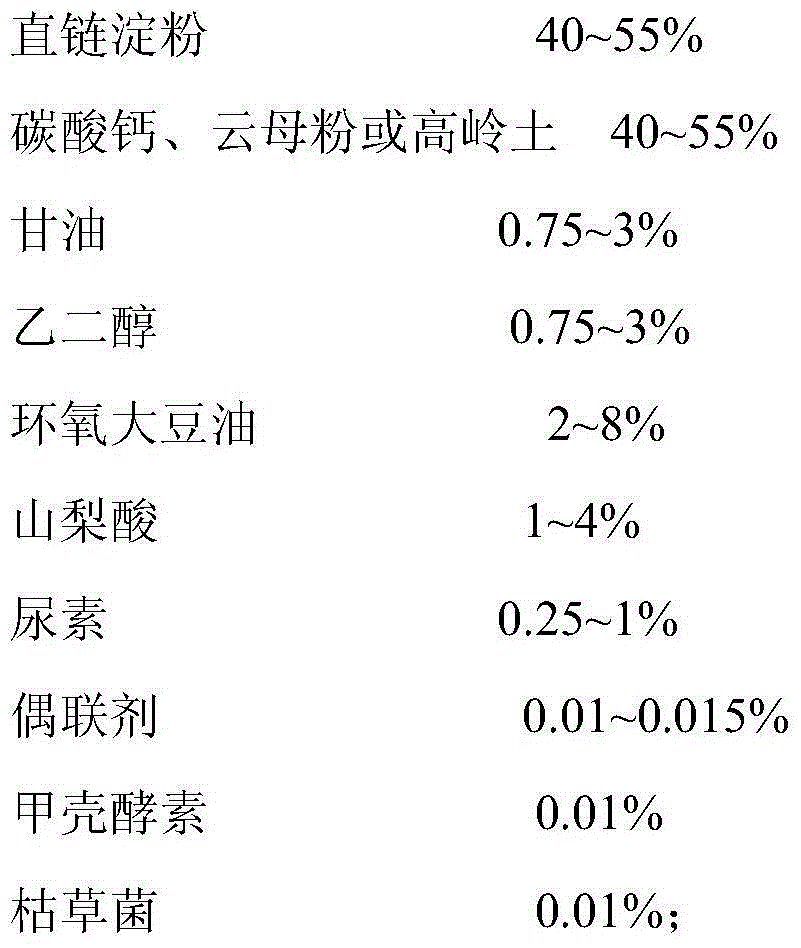

[0041] c. mix and mix polylactic acid masterbatch 10, plant fiber filler 20 and modifier accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com