Protective jacket rubber for marine cable

A technology for sheathing rubber and marine cables, applied in the field of sheathing rubber, can solve problems such as limited use range and large permanent deformation, and achieve the effects of improving large permanent deformation, improving elasticity, and good resistance to chemical medium corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

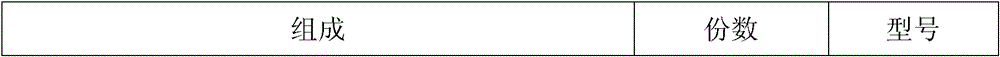

[0028] The composition of the marine cable sheath rubber of the present embodiment, proportioning number and model are shown in Table 1:

[0029] Table I

[0030]

[0031]

[0032] In this example:

[0033] Properties of mixed film:

[0034] Mooney viscosity M(1+4) at 100°C is: 36.0Mv

[0035] The maximum torque MH at 170℃*15min on the rheometer is: 2.60N.m

[0036] The process scorch time t10 at 170℃*15min on the rheometer is: 1.10min

[0037] The process positive vulcanization time t90 at 170℃*15min on the rheometer is: 8.40min

[0038] Tensile strength: 15.5N / mm 2

[0039] Elongation: 350%

[0040] Oxygen Index: 33.5

[0041] Specific gravity: 1.51g / cm 3

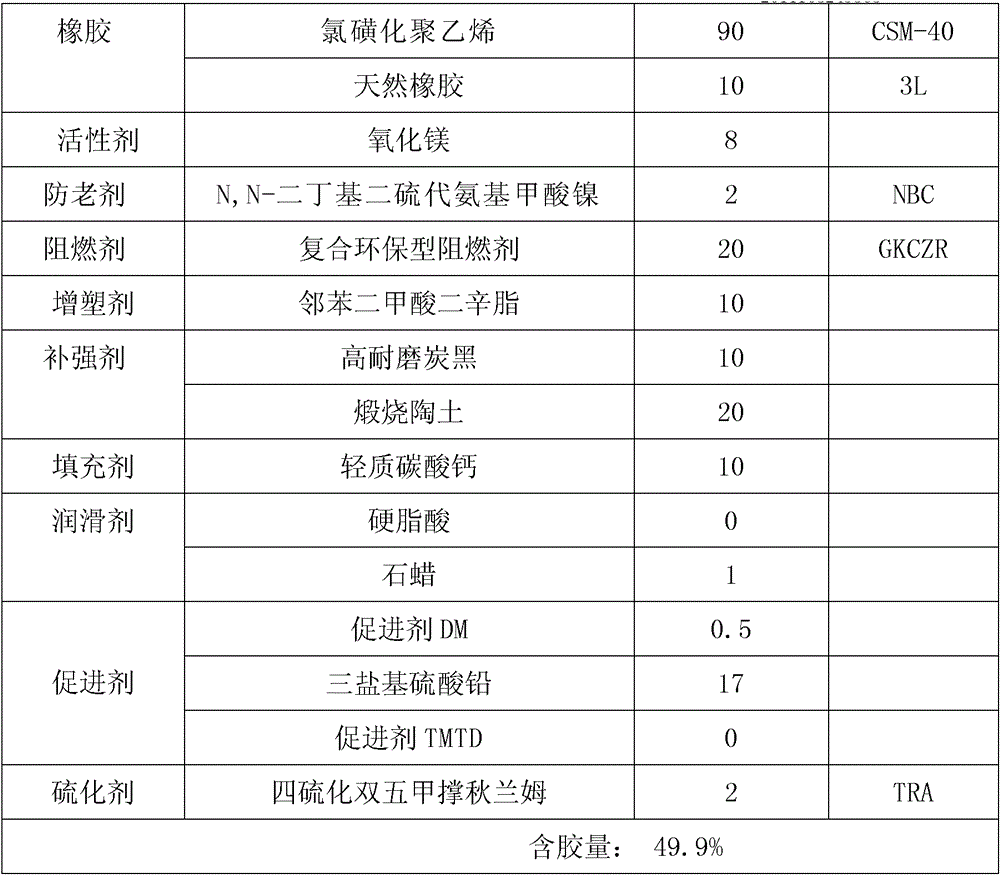

[0042] After weighing according to Table 1, perform mastication, kneading, tableting, extrusion molding, and steam vulcanization to obtain the finished product, and its properties are shown in Table 2:

[0043] Table II

[0044]

Embodiment 2

[0046] The composition of the marine cable sheath rubber of the present embodiment, proportioning number and model are shown in Table 3:

[0047] Table three

[0048]

[0049] In this example:

[0050] Properties of mixed film:

[0051] Mooney viscosity M(1+4) at 100°C is: 39.0Mv

[0052] The maximum torque MH at 170℃*15min on the rheometer is: 3.00N.m

[0053] The process scorch time t10 at 170℃*15min on the rheometer is: 1.01min

[0054] The process positive vulcanization time t90 at 170℃*15min on the rheometer is: 8.04min

[0055] Tensile strength: 14.1N / mm 2

[0056] Elongation: 340%

[0057] Oxygen Index: 34.0

[0058] Specific gravity: 1.54g / cm 3

[0059] After weighing according to Table 3, carry out mastication, kneading, tableting, extrusion molding, and steam vulcanization to obtain the finished product, and its properties are shown in Table 4:

[0060] Table four

[0061]

Embodiment 3

[0063] The composition of the marine cable sheath rubber of the present embodiment, proportioning number and model are shown in Table five:

[0064] Table five

[0065]

[0066]

[0067] In this example:

[0068] Properties of mixed film:

[0069] Mooney viscosity M(1+4) at 100°C is: 44.0Mv

[0070] The maximum torque MH at 170℃*15min on the rheometer is: 3.40N.m

[0071] The process scorch time t10 at 170℃*15min on the sulfur rheometer is: 1.62min

[0072] The process positive vulcanization time t90 at 170℃*15min on the rheometer is: 12.2min

[0073] Tensile strength: 12.5N / mm 2

[0074] Elongation: 370%

[0075] Oxygen Index: 35.0

[0076] Specific gravity: 1.60g / cm 3

[0077] After weighing according to Table 5, carry out mastication, kneading, tableting, extrusion molding, and steam vulcanization to obtain the finished product, and its properties are shown in Table 6:

[0078] Table six

[0079]

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com