Fire-resistant cable

A fire-resistant cable and cable technology, applied in the field of fire-resistant cables, can solve the problems of poor waterproof and mechanical properties, fire-resistant and flame-retardant performance needs to be improved, and unsatisfactory flame-retardant effects, etc., to achieve good corona resistance and arc resistance , long service life, good resilience effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

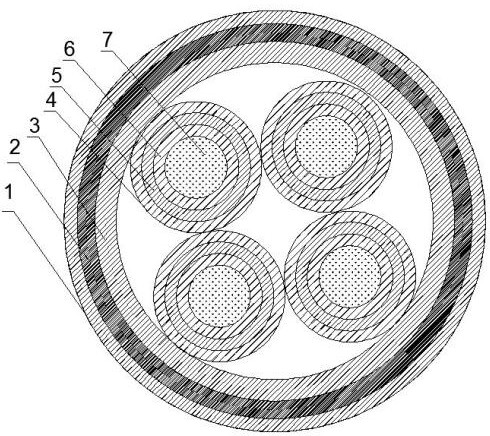

[0025] Such as figure 1 As shown, this embodiment provides a fire-resistant cable, including a cable core and an outer protective sheath wrapped around the cable core; the cable core includes a conductive core 7 and is wrapped on the conductive core 7 The inner protective cover; the outer protective cover is the first insulating layer 3, the filling interlayer 2 and the second insulating layer 1 from the inside to the outside; the inner protective cover is the first protective layer 6 from the inside to the outside, and the third insulating layer Layer 5 and the second protective layer 4. The materials of the first insulating layer 3 , the second insulating layer 1 and the third insulating layer 5 are all polyethylene. The filling interlayer 2 is steel wire wrapped with polyethylene. The second protective layer 4 is silicone rubber.

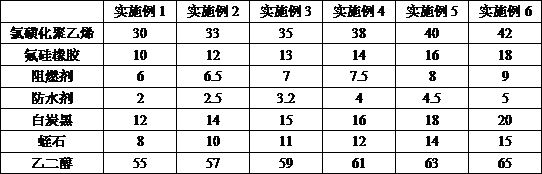

[0026] The first protective layer 6 is made of raw materials in parts by weight shown in Table 1, wherein the flame retardant is chlorinated ...

Embodiment 2

[0028] This embodiment provides a fire-resistant cable, the difference in Embodiment 1 is that the first protective layer described in this embodiment is made of the raw materials shown in Table 1, wherein the flame retardant is boric acid Sodium, the water repellent is calcium stearate.

Embodiment 3

[0030] This embodiment provides a fire-resistant cable. The difference in Embodiment 1 is that the first protective layer described in this embodiment is made of raw materials in parts by weight shown in Table 1, wherein the flame retardant is three Antimony oxide, the waterproofing agent is calcium stearate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com