Ship electric cable sheath rubber

A sheathed rubber, marine cable technology, used in insulated cables, cables, circuits, etc., can solve the problems of poor weather resistance and easy cracking, and achieve the effects of improving permanent deformation, improving elasticity, and good resistance to chemical medium corrosion.

Inactive Publication Date: 2015-06-03

CHANGZHOU XIAOGUO INFORMATION SERVICES

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, natural rubber and styrene-butadiene rubber are mostly used for cable sheath rubber. This kind of cable sheath rubber has good elasticity, but its weather resistance is poor, and it is easy to crack during actual use.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

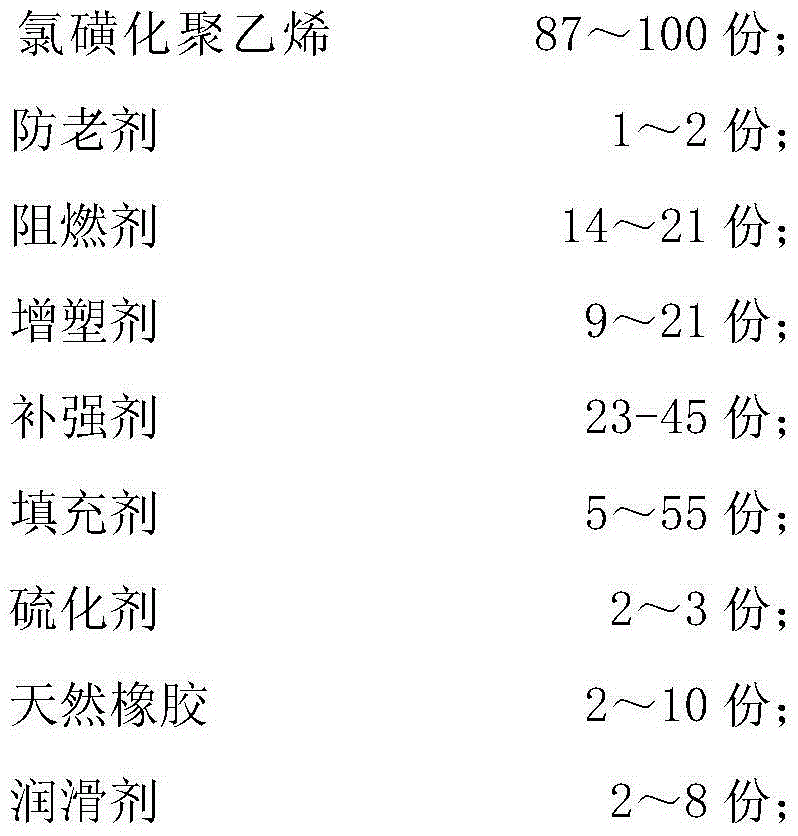

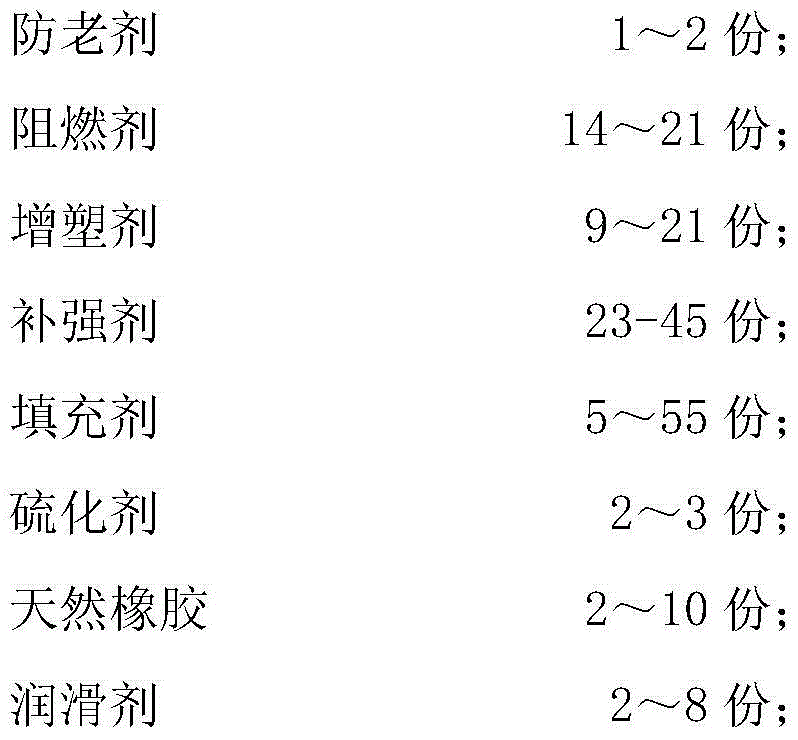

[0009] A kind of sheath rubber for marine cables, the composition and proportioning of the sheath rubber include by parts by mass:

[0010]

[0011]

[0012] The glue content of described sheath rubber is 45~55%;

[0013] The rubber content is (weight of chlorosulfonated polyethylene+weight of natural rubber) / total weight×100%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a ship electric cable sheath rubber, which comprises 87-100 parts of chlorosulfonated polyethylene, 1-2 parts of an anti-aging agent, 14-21 parts of a fire retardation agent, 9-21 parts of a plasticizer, 23-45 parts of a reinforcing agent, 5-55 parts of a filler, 2-3 parts of a vulcanizing agent, 2-10 parts of natural rubber, and 2-8 parts of a lubricant, wherein the gel content of the sheath rubber is 45-55% and is (the weights of the chlorosulfonated polyethylene and the natural rubber) / the total weight*100%. According to the present invention, the chlorosulfonated polyethylene and the natural rubber are selected and used for performance complementing so as to provide good performances.

Description

technical field [0001] The invention relates to a sheath rubber for cables, in particular to a sheath rubber for marine cables. Background technique [0002] At present, natural rubber and styrene-butadiene rubber are mostly used for cable sheath rubber. This kind of cable sheath rubber has good elasticity, but its weather resistance is poor, and it is easy to crack during actual use. Contents of the invention [0003] The purpose of the present invention is to solve the above-mentioned shortcomings, and to provide a sheath rubber for marine cables. [0004] Achieving the technical solution of the object of the present invention is a kind of sheath rubber for marine cables, and the composition and proportioning of the sheath rubber include by parts by mass: [0005] [0006] The glue content of described sheath rubber is 45~55%; [0007] The rubber content is (weight of chlorosulfonated polyethylene+weight of natural rubber) / total weight×100%. [0008] After adopting...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L23/34C08L7/00H01B3/28H01B7/17

CPCC08L23/34C08L2201/02C08L2203/202H01B3/28H01B3/441H01B7/17

Inventor 顾晓刚

Owner CHANGZHOU XIAOGUO INFORMATION SERVICES

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com