Ibuprofen arginine tablet and preparation method thereof

A technology of arginine ibuprofen and tablets, which can be used in anti-inflammatory agents, pill delivery, pharmaceutical formulations, etc., can solve the problems of large amount of excipients, achieve rapid onset, high safety, and correct the effect of liver toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

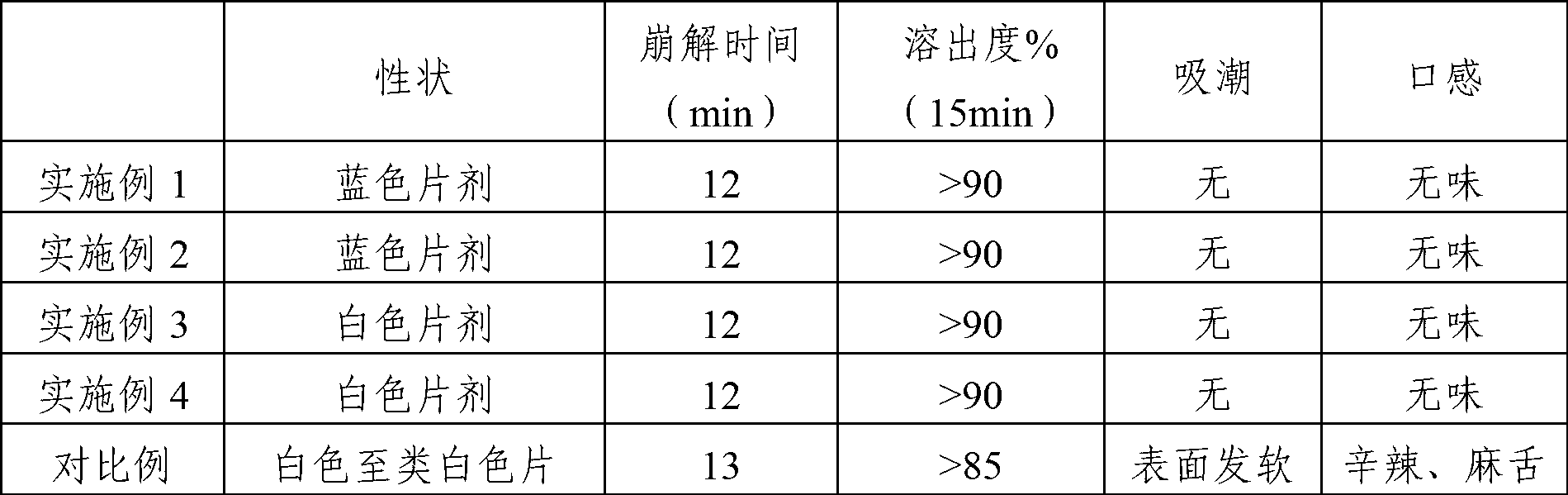

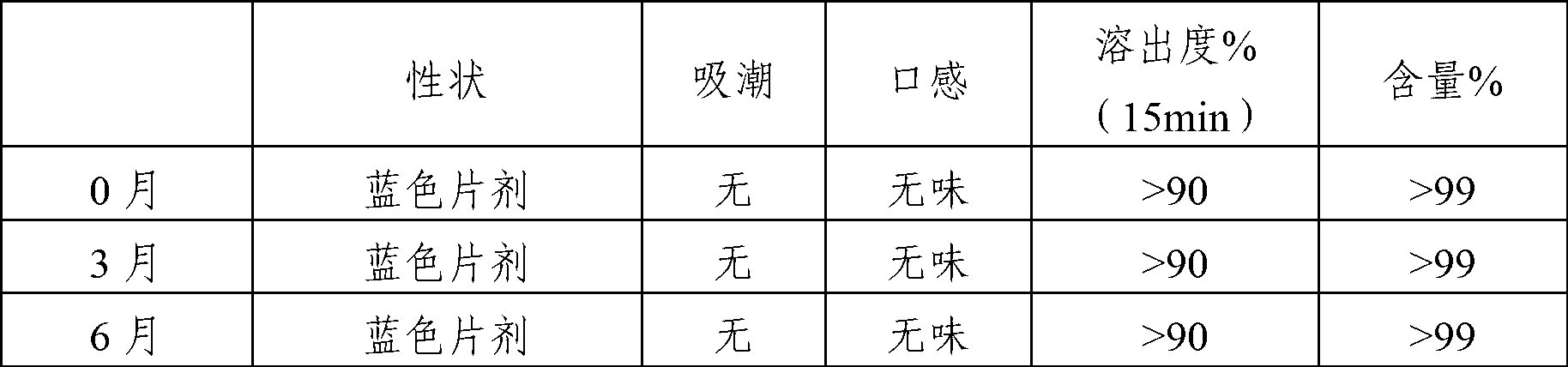

Examples

Embodiment 1

[0033] 1. For every 1000 arginine ibuprofen tablets, weigh the materials according to the following formula:

[0034] Arginine ibuprofen: 370.0g;

[0035] Crospovidone: 18.5g;

[0036] Gastric-soluble film coating premix: 16.3g;

[0037] Magnesium stearate: 4.0 g.

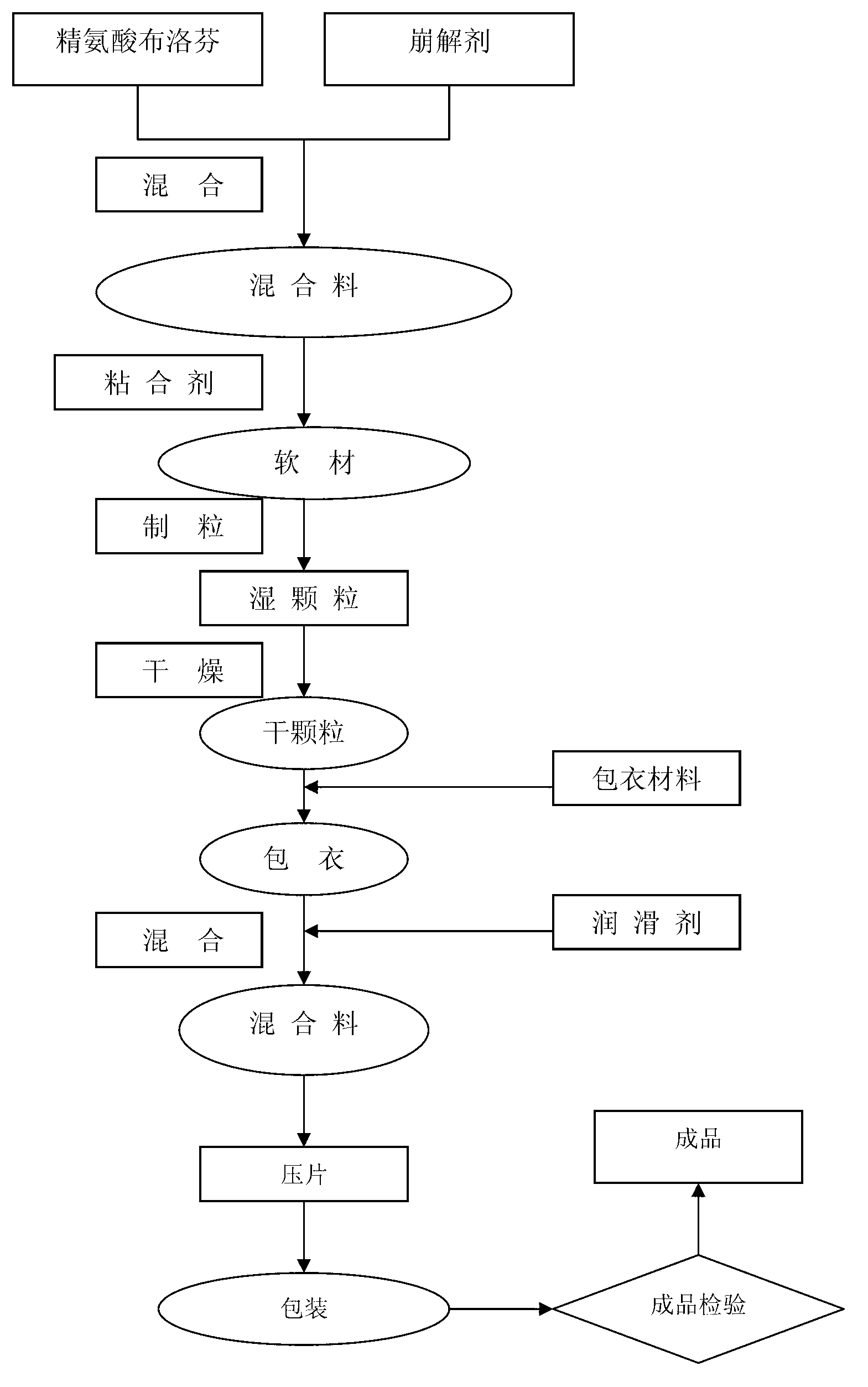

[0038] 2. The preparation process (such as figure 1 shown)

[0039] (1) Crush ibuprofen arginine and pass through a 80-mesh sieve, mix it with crospovidone in a tank mixer for about 30 minutes, then add an appropriate amount of purified water into the aforementioned tank mixer and stir for about 30 minutes Minutes to make soft materials.

[0040] (2) Pass the soft material through a 40-mesh sieve for oscillating granulation, dry the wet granules in a blast drying oven at 60°C, and pass the obtained dry granules through a 40-mesh sieve for granulation.

[0041] (3) Dissolve the gastric-soluble film coating premix in purified water, stir for about 45 minutes, and make a coating solution with a solid content of ...

Embodiment 2

[0044] 1. For every 1000 arginine ibuprofen tablets, weigh the materials according to the following formula:

[0045] Arginine ibuprofen: 370.0g;

[0046] Croscarmellose sodium: 14.3g;

[0047] Gastric-soluble film coating premix: 10.0g;

[0048] Magnesium stearate: 4.0 g.

[0049] 2. Preparation process

[0050] (1) Crush ibuprofen arginine and pass through 80 sieves, mix with croscarmellose sodium in a tank mixer for about 30 minutes, then add an appropriate amount of purified water into the aforementioned tank mixer and stir About 30 minutes to make soft materials.

[0051] (2) Pass the soft material through a 40-mesh sieve for oscillating granulation, dry the wet granules in a blast drying oven at 60°C, and pass the obtained dry granules through a 40-mesh sieve for granulation.

[0052] (3) Dissolve the gastric-soluble film coating premix in purified water, stir for about 45 minutes, and make a coating solution with a solid content of about 16wt% for later use, and pl...

Embodiment 3

[0055] 1. For every 1000 arginine ibuprofen tablets, weigh the materials according to the following formula:

[0056] Arginine ibuprofen: 370.0g;

[0057] Sodium carboxymethyl starch: 12.1g;

[0058] Hypromellose: 11.0g;

[0059] Micro silica gel: 2.4g;

[0060] Magnesium stearate: 1.2g.

[0061] 2. Preparation process

[0062] (1) Grind ibuprofen arginine and pass through 80 sieves, mix it with sodium carboxymethyl starch in a tank mixer for about 30 minutes, then add an appropriate amount of 5wt% ethanol aqueous solution into the aforementioned tank mixer and stir About 30 minutes to make soft materials.

[0063] (2) Pass the soft materials through 40 sieves for shaking granulation, dry the wet granules in a blast drying oven at 65°C, and pass the obtained dry granules through 40 sieves for granulation.

[0064] (3) Dissolve hypromellose in purified water and stir for about 30 minutes to make a coating solution with a solid content of about 12wt% for later use. Put the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com