Schottky diode and its manufacturing method

A technology of Schottky diodes and anodes, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems affecting the performance of Schottky diodes, chip yield, low reverse breakdown voltage of Schottky diodes, increase Production costs and other issues, to achieve the effect of easy practical operation, low cost, and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

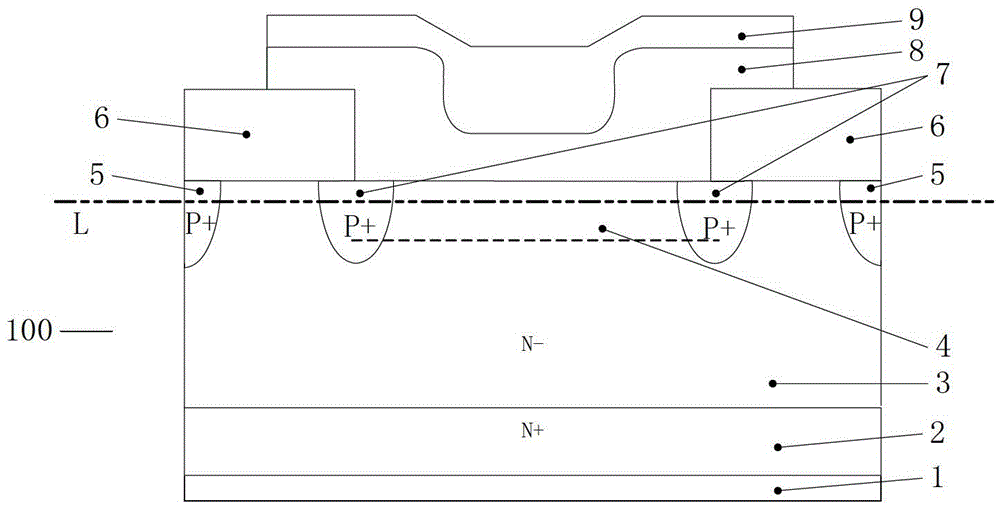

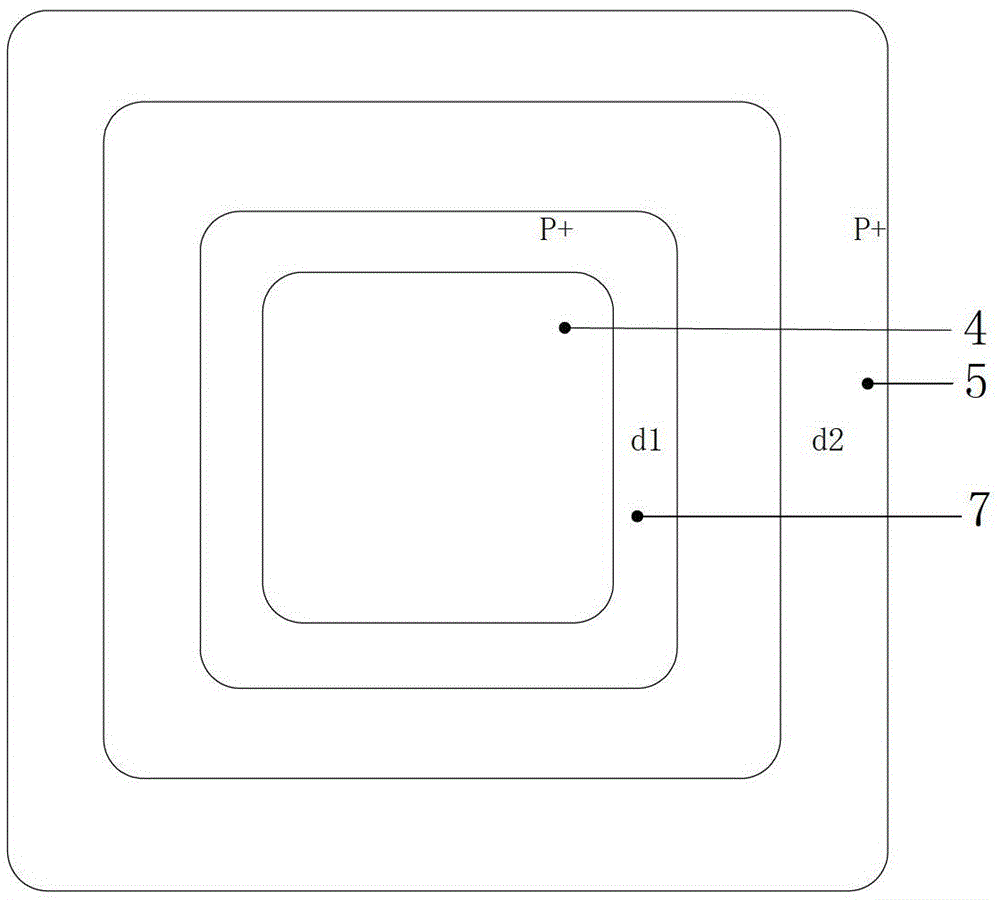

[0054] Using the above manufacturing method, a Schottky diode with a reverse breakdown voltage of 30V was fabricated. In the Schottky diode, the width d1 of the P+ inner ring is about 18 μm, and the width d2 of the P+ outer ring is about 40 μm. The dose of boron ion implantation is about 1×10 14 cm -2 , the depths of the inner and outer rings of P+ are about 2 μm respectively, and the design target parameters are reverse breakdown voltage V R ≥30V, V R I = 20V R ≤45μA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com