Water-based expandable fireproof steel structure coating and preparation method

A technology for fire-resistant coatings and section steel, applied in fire-resistant coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor water resistance, poor high temperature resistance, poor aging resistance, etc., achieve strong weather resistance, improve dispersion performance, and improve physical and chemical properties performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

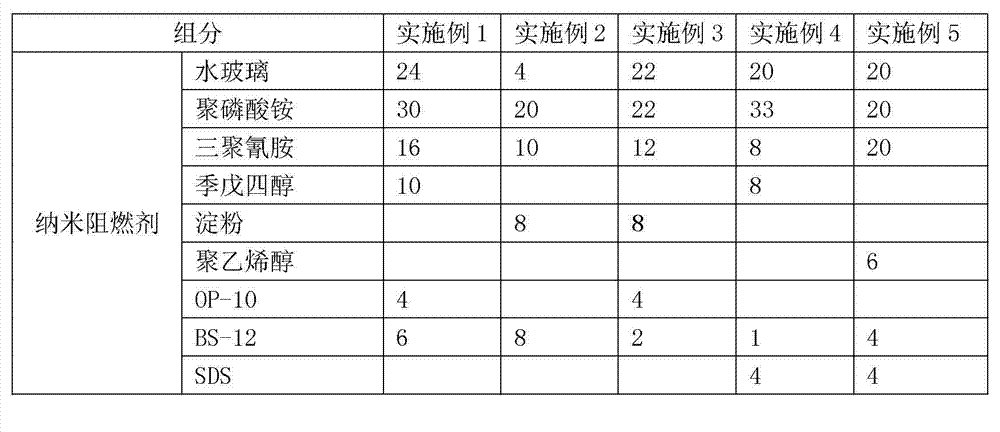

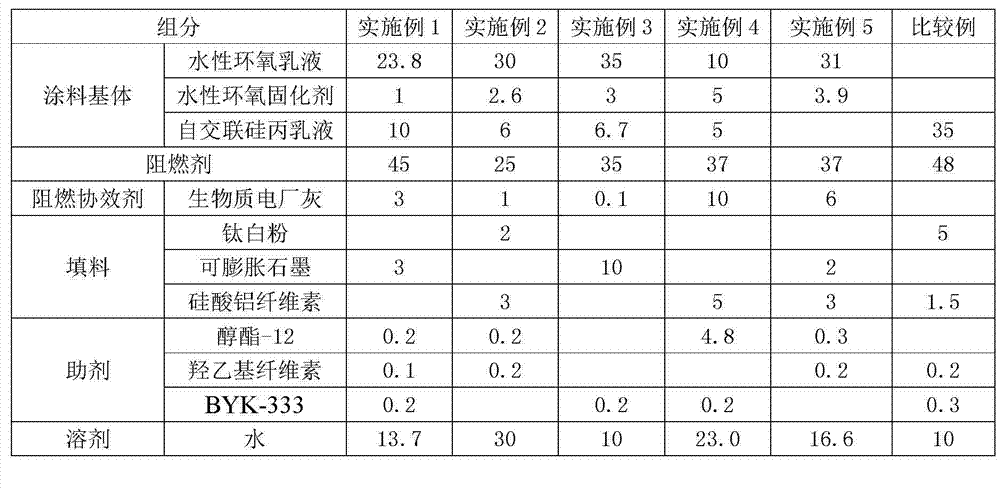

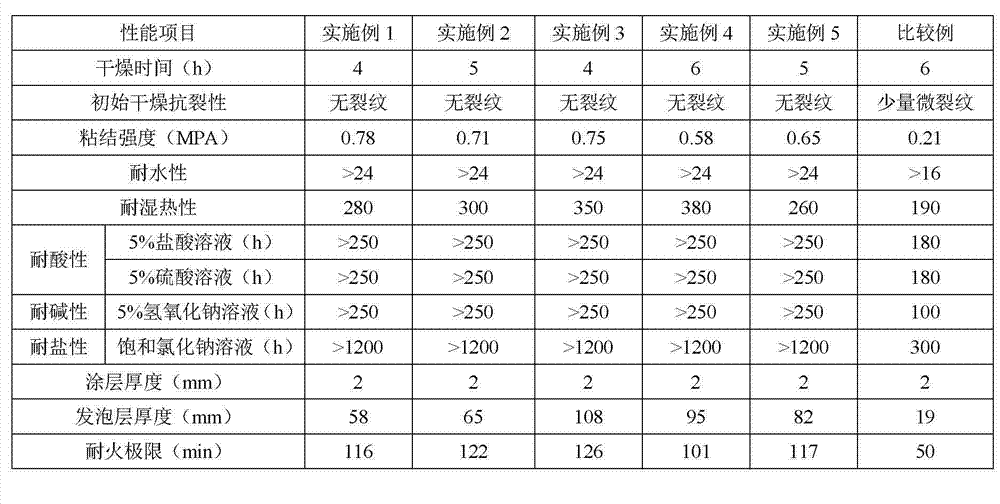

[0034] Please refer to the fire retardant coating formulations of the present invention listed in Table 1 and Table 2.

[0035] (1) Preparation of nano flame retardant:

[0036] Each flame retardant raw material, water glass and tensio-active agent are joined in the water that is 5 times of flame retardant raw material weight and are heated to 85 o After C, adjust the pH value to 6.5 with dilute sulfuric acid, cool, filter and wash the reaction product after reacting for two hours, and obtain the nano flame retardant after drying.

[0037] (2) Preparation of fire retardant coating:

[0038] First add water-based epoxy emulsion, water-based epoxy curing agent and self-crosslinking silicone acrylic emulsion into the mixing tank, after stirring evenly, add nano flame retardant, flame retardant synergist, filler, auxiliary agent and appropriate amount of water, stir for 30 Add it to the ball mill and grind once after mixing evenly. After uniform mixing, use a scraper fineness me...

Embodiment 2

[0041]Please refer to the fire retardant coating formulations of the present invention listed in Table 1 and Table 2.

[0042] (1) Preparation of nano flame retardant:

[0043] Each flame retardant raw material, water glass and tensio-active agent are joined in the water that is 4 times of flame retardant raw material weight and are heated to 90 o After C, adjust the pH value to 7.0 with dilute hydrochloric acid, cool, filter and wash the reaction product after reacting for two hours, and obtain the nano flame retardant after drying.

[0044] (2) Preparation of fire retardant coating:

[0045] First add water-based epoxy emulsion, water-based epoxy curing agent and self-crosslinking silicone acrylic emulsion into the mixing tank, after stirring evenly, add nano flame retardant, flame retardant synergist, filler, auxiliary agent and appropriate amount of water, and stir for 15 minutes Then add it to the ball mill for grinding once, after uniform mixing, use a scraper fineness...

Embodiment 3

[0048] Please refer to the fire retardant coating formulations of the present invention listed in Table 1 and Table 2.

[0049] (1) Preparation of nano flame retardant:

[0050] Each flame retardant raw material, water glass and tensio-active agent are joined in the water that is 3 times of flame retardant raw material weight and are heated to 50 o After C, adjust the pH value to 7.5 with dilute sulfuric acid, cool, filter and wash the reaction product after reacting for two hours, and obtain the nano flame retardant after drying.

[0051] (2) Preparation of fire retardant coating:

[0052] First add water-based epoxy emulsion, water-based epoxy curing agent and self-crosslinking silicone acrylic emulsion into the mixing tank, after stirring evenly, add nano flame retardant, flame retardant synergist, filler, auxiliary agent and appropriate amount of water, and stir for 20 minutes Then add it to the ball mill for grinding once, after uniform mixing, use a scraper fineness me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com