PVB (polyvinyl butyral) film having heat-insulating property and preparation method thereof

A membrane and performance technology, applied in the field of PVB membrane and its preparation, can solve the problems of ITO nano powder agglomeration, etc., and achieve the effect of solving agglomeration, good heat insulation effect and high blocking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

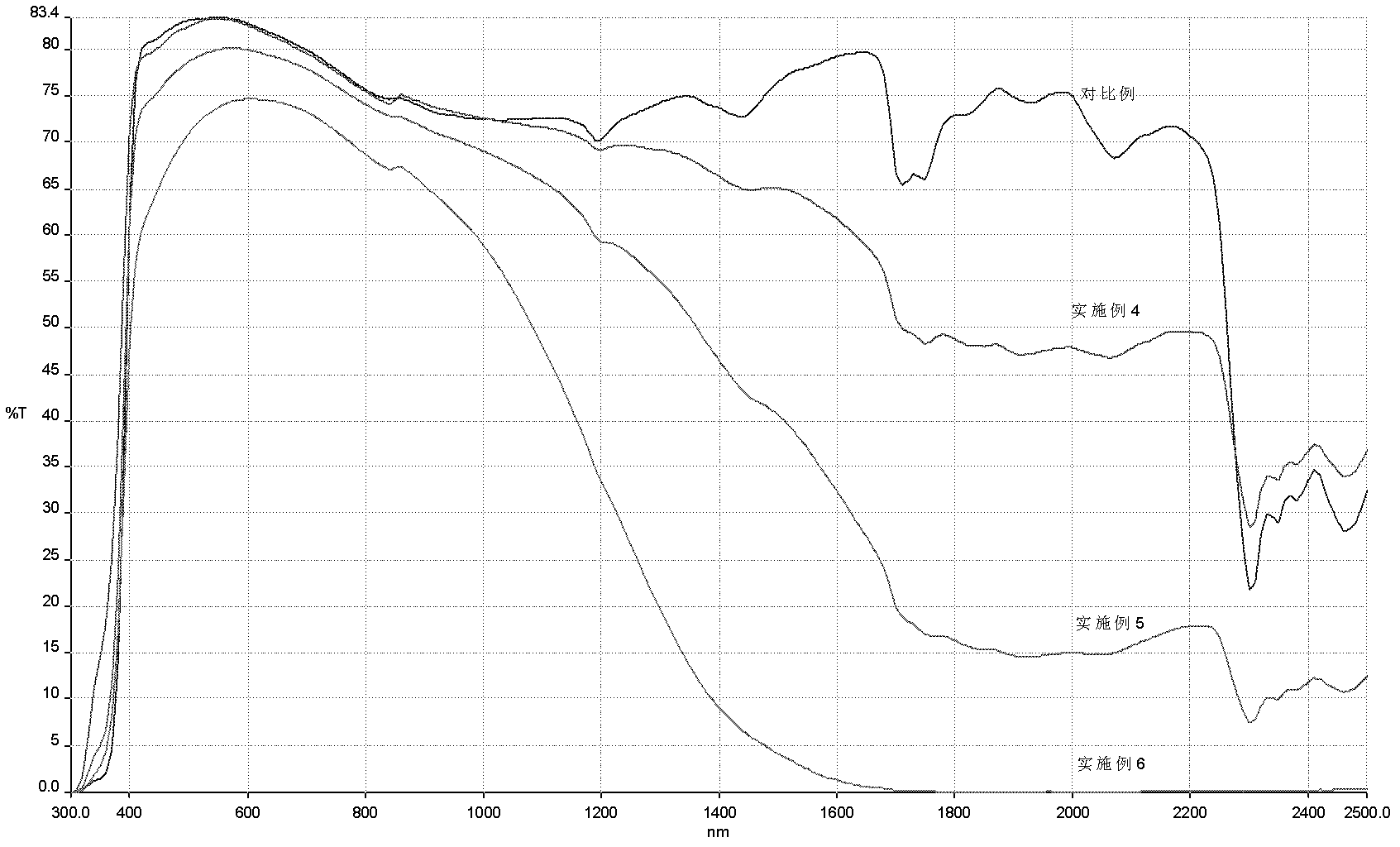

Examples

Embodiment 1

[0042] Take methanol: 84g, PVB resin powder: 5g, ITO nano-powder: 11g, add PVB resin powder into methanol to dissolve, then add ITO nano-powder and grind on a ball mill for 3 hours to prepare nano-ITO emulsion.

Embodiment 2

[0044] Take ethanol: 85g, PVB resin powder: 10g, ITO nano-powder: 5g, add PVB resin powder to ethanol to dissolve, then add ITO nano-powder and grind on a ball mill for 4 hours to prepare nano-ITO emulsion.

Embodiment 3

[0046] Get ethyl acetate: 70g, PVB resin powder: 15g, ITO nano-powder: 15g, add PVB resin powder in ethyl acetate and dissolve, then add ITO nano-powder and grind on a ball mill for 5 hours to make a nano-ITO emulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com