Method for preparing drug-loading nanocomposite through ball-milling modification of mineral soil and application

A nano-composite material and mineral technology, which is applied in the field of pesticides and pharmaceuticals, can solve the problems that the efficient utilization of materials cannot be fully reflected, and the drug loading rate of carrier materials cannot be fundamentally improved. The effect of strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Dissolve 1g of sodium alginate in slowly heated distilled water to prepare 50ml of sodium alginate aqueous solution. After it is completely cooled, mix 200mg of pesticides into the aqueous sodium alginate solution and stir vigorously to make it a uniform mixture. Then prepare 100ml of 0.25M calcium chloride aqueous solution, add 2% (w / v) acetic acid and 0.6% (w / v) CS respectively, stir and mix thoroughly. Finally, the above-mentioned polymer mixture was dripped dropwise into the calcium chloride-chitosan mixed solution with a 25mL hypodermic syringe at a height of 30cm and stirred at a constant speed. After 30 min, the beads were transferred from the gelling agent, filtered and rinsed with distilled water. Dry at room temperature for a while, and finally transfer to an oven to dry at 40°C until constant weight. The obtained composite rubber beads loaded with acetamiprid had an encapsulation rate of 42.13% and a drug loading rate of 4.15%. In the 50% methanol solution ...

Embodiment 2

[0038] A preparation method of drug-loaded nanocomposite rubber beads comprises the following two processes:

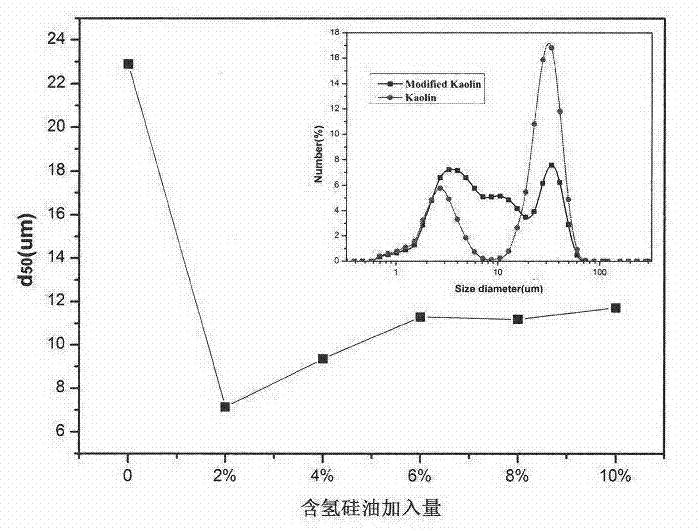

[0039] (1) Drug loading: Put 2 g of kaolin and 0.12 g of hydrogen-containing silicone oil into the tank of the planetary ball mill. Equipped with 1 steel ball in the tank 6 pieces 20 pieces The rotating speed of the main disk is controlled at 516r / min, and the ball milling is performed for 2 hours. Take 1.5g of modified kaolin, 0.5g of cetyltrimethylammonium bromide, 200mg of acetamiprid and 100ml of deionized water, mix together and ultrasonically disperse for 30min. Then the mixed solution is frozen into blocks in a refrigerator, placed in a freeze dryer to continue freezing, vacuumized and dried to obtain the drug-loaded mineral soil.

[0040] (2) Prepare dosage form: Dissolve 1g of sodium alginate in slowly heated distilled water to obtain 50ml of sodium alginate aqueous solution. After it is completely cooled, mix the drug-loaded mineral soil into the aqueo...

Embodiment 3

[0042] A preparation method of drug-loaded nanocomposite rubber beads comprises the following two processes:

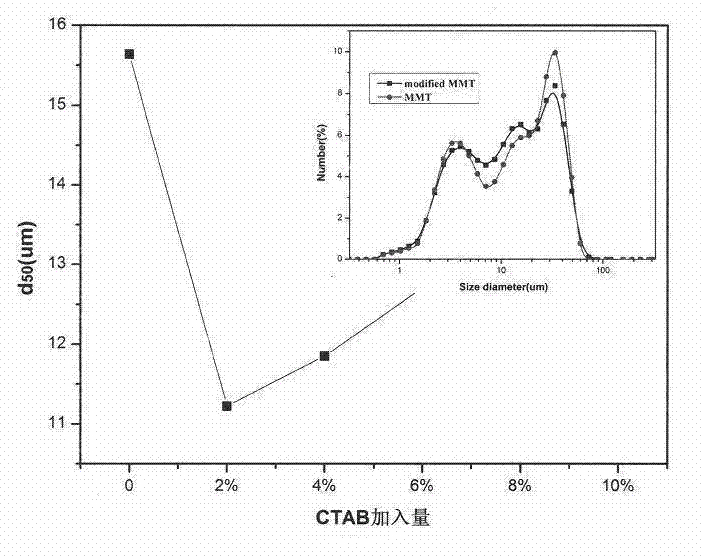

[0043] (1) Drug loading: respectively put 2 g of montmorillonite, 0.08 g of cetyltrimethylammonium bromide, 2 g of kaolin and 0.12 g of hydrogen-containing silicone oil into two tanks in the planetary ball mill. Each tank is equipped with 1 steel ball 6 pieces 20 pieces The rotating speed of the main disk is controlled at 516r / min, and the ball milling is performed for 2 hours. Take 1.25g of modified kaolin, 0.25g of montmorillonite, 0.4g of cetyltrimethylammonium bromide, 200mg of acetamiprid and 100ml of deionized water, mix together and ultrasonically disperse for 30min. Then the mixed solution is frozen into blocks in a refrigerator, placed in a freeze dryer to continue freezing, vacuumized and dried to obtain the drug-loaded mineral soil.

[0044] (2) Prepare dosage form: Dissolve 1g of sodium alginate in slowly heated distilled water to obtain 50ml of sod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com