Method and device for performing high-precision determination of corn ear variety based on images

A corn ear and image realization technology, applied in the fields of seed and rhizome processing, application, agriculture, etc., can solve the problems of long test process cycle, automatic detection error, lack of test test accuracy, accuracy improvement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

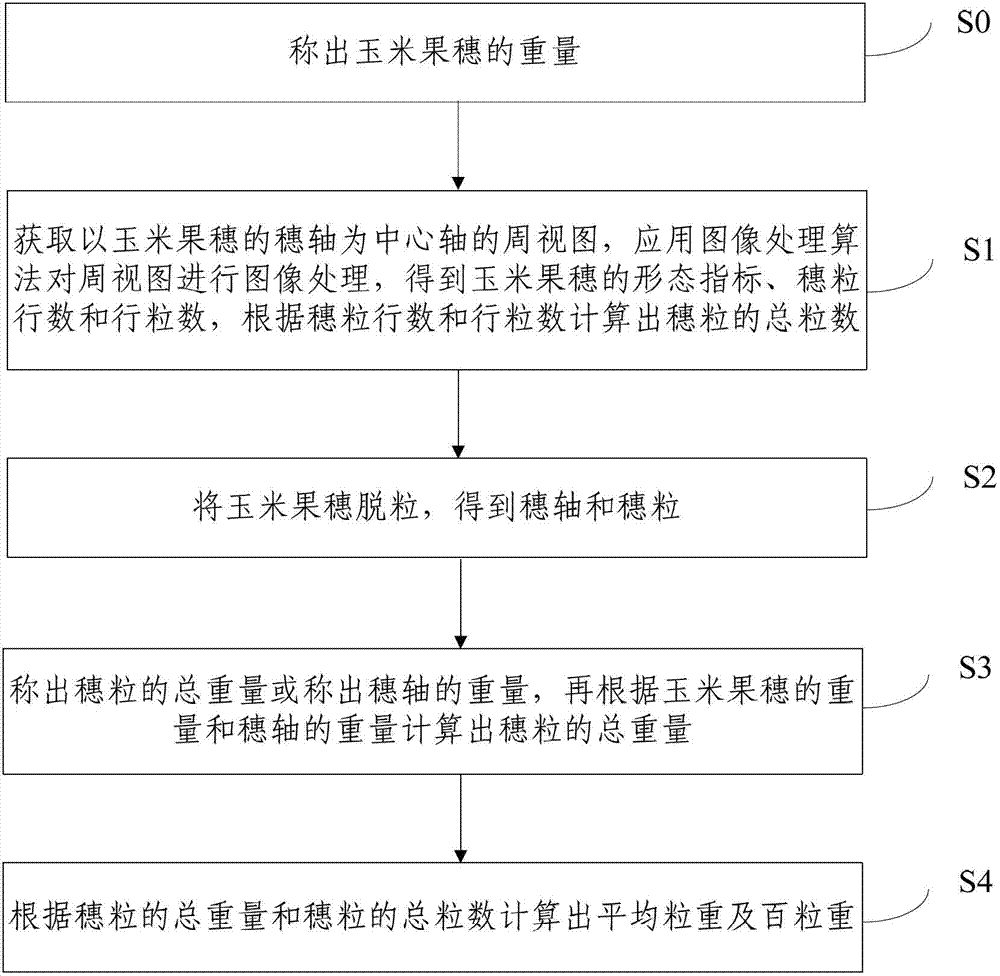

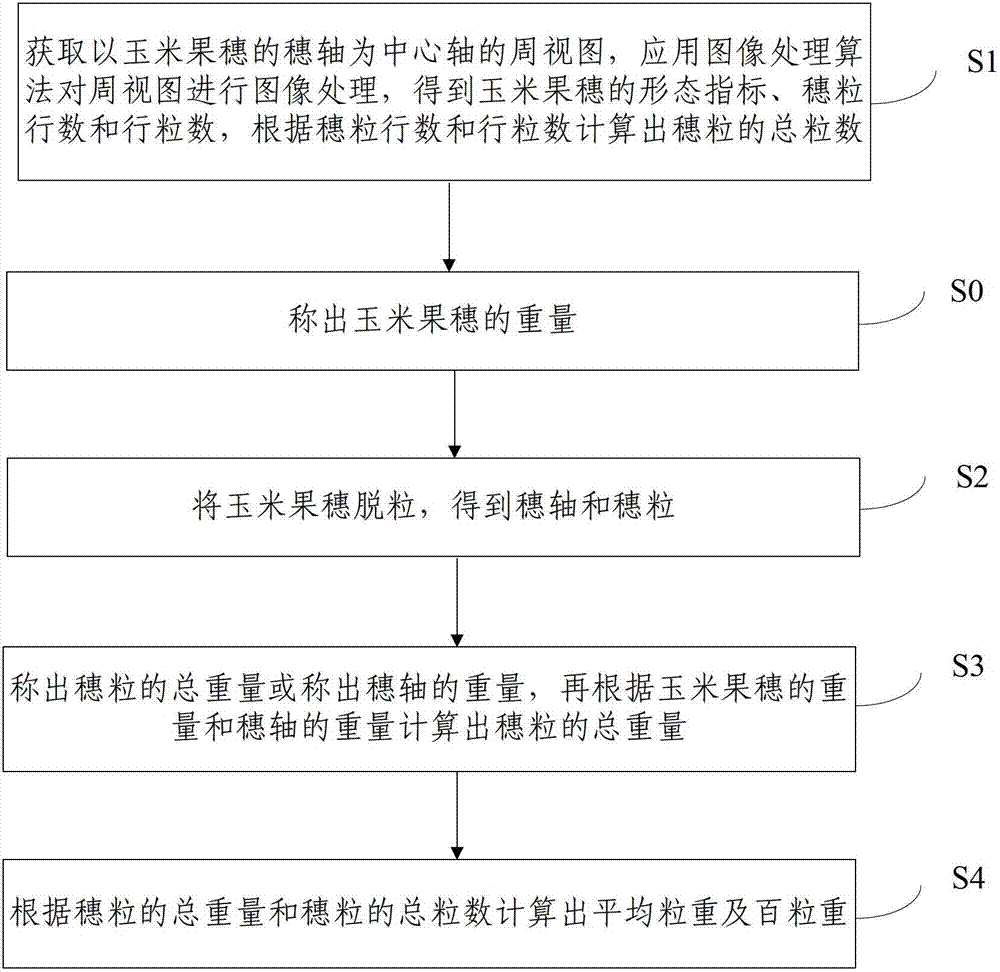

[0048] Embodiment 1 provides a high-precision method for testing corn ears based on images, and the steps are as follows: figure 1 and figure 2 As shown, it specifically includes the following steps:

[0049] S1: Obtain the peripheral view with the cob of the corn ear as the central axis, apply the image processing algorithm to process the image of the peripheral view, and obtain the morphological index of the corn ear, the number of rows of kernels and the number of rows of kernels. The total number of grains per ear was calculated from the number of grains.

[0050] Among them, the morphological indicators include the length of the ear and the diameter of the ear.

[0051] Specifically, there are many ways to realize the peripheral view with the cob of the corn ear as the central axis, three ways are listed in this embodiment, but not limited to these three ways.

[0052] The first method: place the corn ear and the camera vertically or horizontally relative to each othe...

Embodiment 2

[0067] In order to achieve the above object, the second embodiment of the present invention also provides a high-precision corn ear seed testing device based on images, and the seed testing device includes:

[0068] Box 401 , camera 402 , light source 403 , weighing device 404 , and stepping motor 405 , wherein the camera 402 , light source 403 , weighing device 404 and stepping motor 405 are located inside the box body 401 .

[0069] The light source 403 provides light for the camera 402 to take pictures, and the camera 402 is used to obtain a peripheral view with the cob of the corn ear as the central axis.

[0070] The weighing device 404 is used for weighing the weight of corn ears, the weight of cobs or grains after threshing.

[0071] The stepper motor 405 provides power for the corn ear to rotate.

[0072] The placement method of camera 402 and corn ear specifically includes:

[0073] The ear of corn and the camera 402 are placed vertically or horizontally relative to...

Embodiment 3

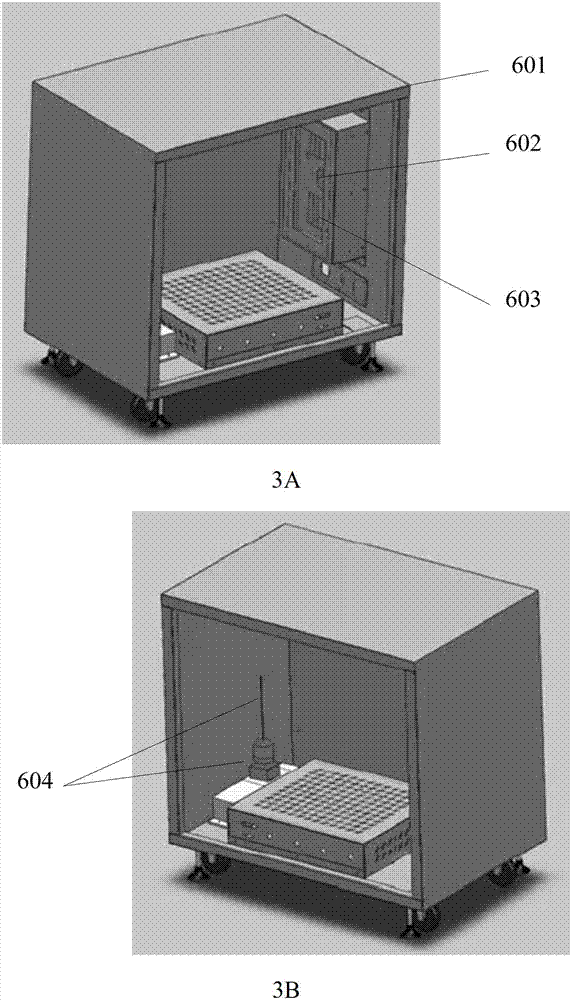

[0078] In order to achieve the above object, the third embodiment of the present invention also provides a high-precision corn ear seed testing device based on images, and the seed testing device includes:

[0079] Cabinet 501, N cameras, light source 503, weighing device 504, the number of N in this embodiment is selected as 4, then the first camera 5021, the second camera 5022, the third camera 5023, the fourth camera 5024, the light source 503 And the weighing device 504 is located inside the box body 501 .

[0080] Wherein the light source 503 provides light for the camera to take pictures, and the first camera 5021, the second camera 5022, the third camera 5023, and the fourth camera 5024 are placed upright or horizontally at the same time, surrounding the ear of corn for a week, and the four cameras are distributed relative to the ear of corn in the center The included angles are 90 degrees.

[0081] The weighing device 504 is used to weigh the weight of the ear of corn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com