Submodule unit of voltage source transverter based on full control components

A voltage source converter and sub-module technology, applied in the output power conversion device, the conversion of AC power input to DC power output, electrical components, etc., can solve the problem of reducing work efficiency and operability, equipment dv/dt stress Large, harsh electromagnetic environment, etc., to achieve the effects of convenient installation and transportation, low output voltage change rate, and insensitive switching device parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

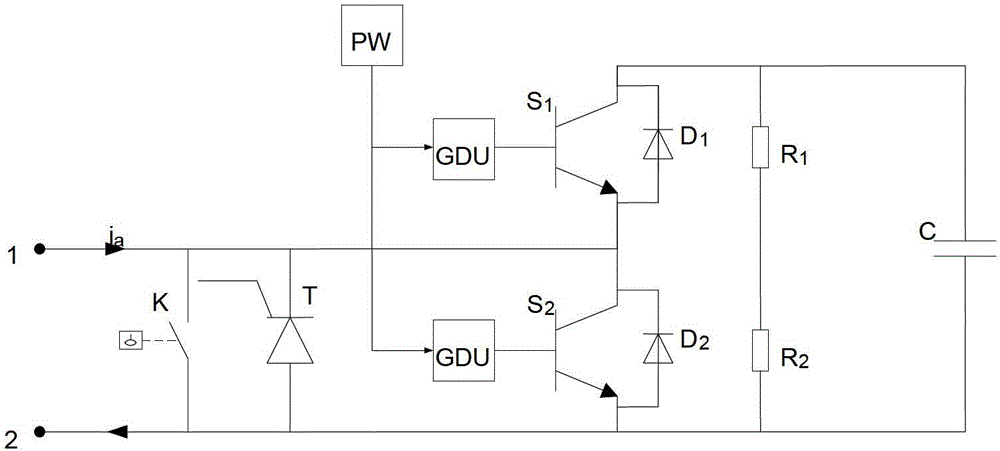

[0042] The sub-module unit of the voltage source converter of this embodiment adopts an independent control mode, and the electrical schematic diagram of the sub-module unit is as follows figure 1 As shown, this is the parallel structure of the IGBT module and the capacitor of the half-bridge structure. In this embodiment, the half-bridge structure or the upper half of the H-bridge structure is defined as the upper-side IGBT module, for example figure 1 The IGBT module composed of the IGBT (S1) and the built-in diode D1 in parallel is the upper tube IGBT module (referred to as the upper IGBT), and the lower part of the half bridge structure or the H bridge structure is the lower tube IGBT module, for example figure 1 The IGBT module composed of the IGBT (S2) and the built-in diode D2 connected in parallel is a lower-side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com