Zero-tooth-difference internal gear pair transmission mechanism with planetary gear elastic deformation ring

A planetary gear, elastic deformation technology, applied in the direction of gear transmissions, transmissions, elements with teeth, etc., can solve the problems of reduced load capacity, long axial length, intermittent uneven rotation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

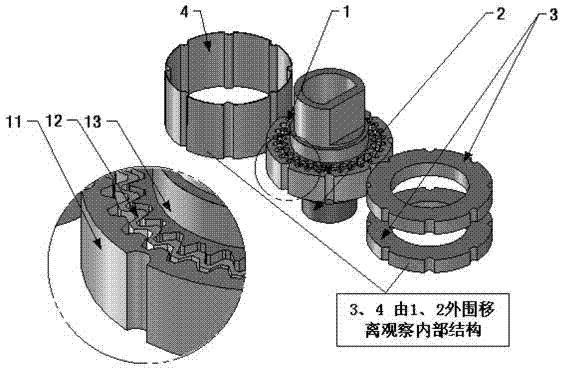

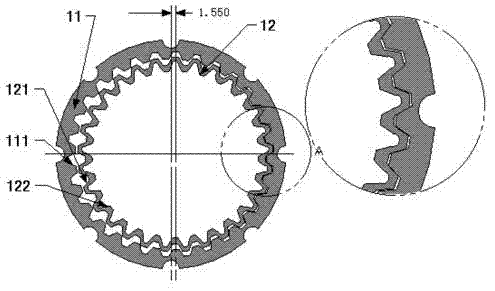

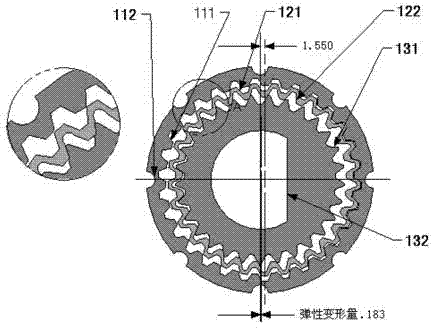

[0007] Below we describe the present invention in detail in conjunction with the accompanying drawings. Implementation method: Referring to Figures 1, 2, and 3, the zero-tooth-difference internal gear pair transmission mechanism is composed of a set of zero-tooth-difference internal gear pairs [1], one eccentric shaft [2], two end covers [3] and one The pressure riveting ferrule [4] and so on; the zero-tooth-difference internal gear pair consists of an internal gear (11), a planetary gear elastic deformation ring (12) and a planetary gear elastic deformation ring (12) with the same number of teeth The zero-tooth-difference gear output shaft (13) constitutes a gear pair; the tooth shape of the internal gear (11) is an arc or straight line fitted with an involute curve (111) or an involute curve; the outer periphery of the internal gear has 8 Two semi-cylindrical grooves evenly distributed around the circumference are used to install the pressure riveting ring and position and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com