Clutch facing without rubber winding and preparation method thereof

A clutch face and rubber technology, applied in the direction of mechanical equipment, friction linings, etc., can solve the problems of poor heat resistance, environmental pollution, unstable friction performance, etc., achieve high rotational burst strength, reduce production costs, and produce products The effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The water-soluble phenolic resin is composed of phenolic resin with a mass percentage of 60% and water with a mass percentage of 40%.

[0019] The gel substitute composite powder is formed by mixing 40% rosin by mass percentage and 60% light calcium carbonate by mass. The crystal grain shape of the light calcium carbonate is spherical and the particle size is 100nm. The particle size of the substitute glue composite powder is 180 mesh.

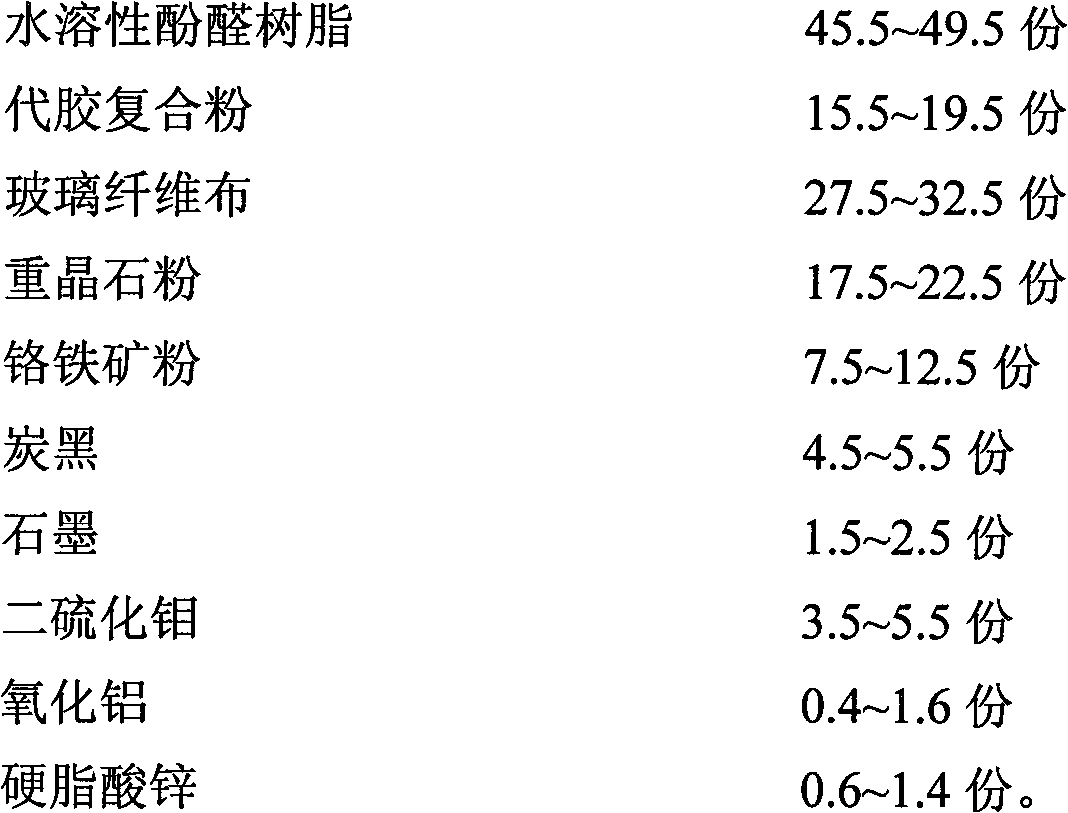

[0020] Then weigh according to the following formula:

[0021] 45.5 parts of water-soluble phenolic resin, 15.5 parts of rubber substitute compound powder, 17.5 parts of barite powder, 7.5 parts of chromite powder, 4.5 parts of carbon black, 1.5 parts of graphite, 3.5 parts of molybdenum disulfide, 0.4 parts of alumina, stearic acid 0.6 parts of zinc, 27.5 parts of glass fiber cloth

[0022] Mix water-soluble phenolic resin, rubber substitute compound powder, barite, chromite powder, carbon black, graphite, molybdenum disulfide, alumi...

Embodiment 2

[0031] The water-soluble phenolic resin is composed of phenolic resin with a mass percentage of 50% and water with a mass percentage of 50%.

[0032] The gel substitute composite powder is mixed with 50% rosin and 50% light calcium carbonate by mass percentage. The crystal grain shape of the light calcium carbonate is spherical and the particle size is 50nm. The particle size of the glue substitute composite powder is 170 mesh.

[0033] Then weigh according to the following formula:

[0034] 47.5 parts of water-soluble phenolic resin, 17.5 parts of rubber substitute compound powder, 19.5 parts of barite powder, 9.5 parts of chromite powder, 5.0 parts of carbon black, 2.0 parts of graphite, 4.0 parts of molybdenum disulfide, 0.9 parts of alumina, stearic acid 1.1 parts of zinc, 29.5 parts of glass fiber cloth

[0035] Mix water-soluble phenolic resin, rubber substitute compound powder, barite, chromite powder, carbon black, graphite, molybdenum disulfide, aluminum oxide, and ...

Embodiment 3

[0045] The water-soluble phenolic resin is composed of phenolic resin with a mass percentage of 40% and water with a mass percentage of 60%.

[0046] The gel substitute compound powder is mixed with 60% rosin by mass percentage and 40% light calcium carbonate by mass. The crystal grain shape of the light calcium carbonate is spherical and the particle size is 20nm. The particle size of the glue substitute compound powder is 160 mesh.

[0047] Then weigh according to the following formula:

[0048] 49.5 parts of water-soluble phenolic resin, 19.5 parts of rubber substitute compound powder, 22.5 parts of barite powder, 12.5 parts of chromite powder, 5.5 parts of carbon black, 2.5 parts of graphite, 5.5 parts of molybdenum disulfide, 1.6 parts of aluminum oxide, stearic acid 1.4 parts of zinc, 32.5 parts of glass fiber cloth.

[0049] Mix water-soluble phenolic resin, rubber substitute compound powder, barite, chromite powder, carbon black, graphite, molybdenum disulfide, alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com