Method for preparing rubber or resin multifunctional anti-aging agent

A multi-functional, antioxidant technology, applied in the direction of organic chemistry, etc., can solve problems such as the inability of antioxidants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with specific embodiments.

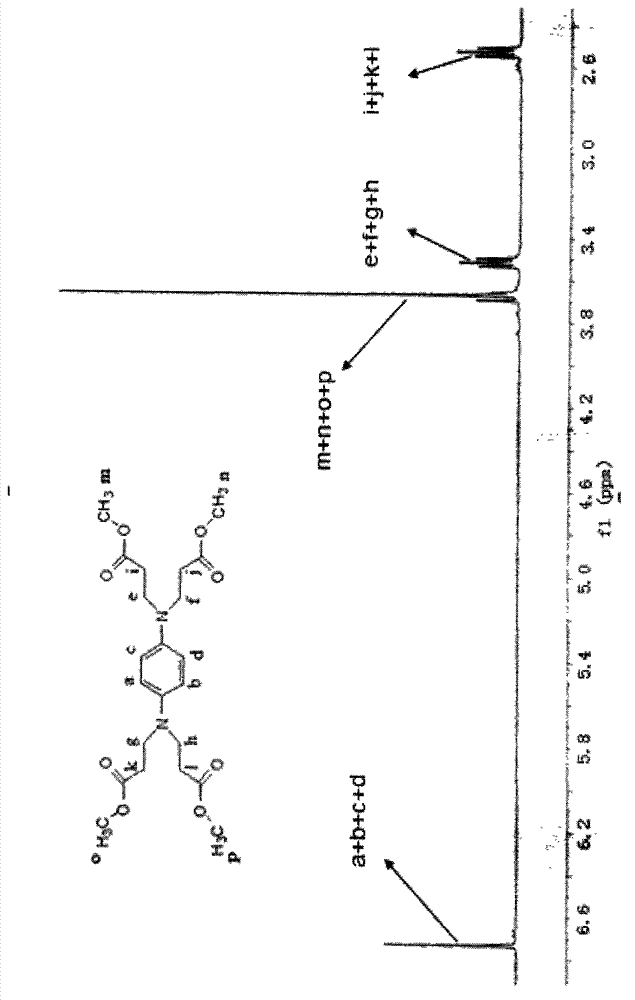

[0014] Synthesis of a New Multifunctional Antiaging Agent

[0015] 1.1 Preparation of intermediates

[0016] Add p-phenylenediamine and methyl acrylate to the three-necked flask, the dosage is 1:3.5~1:5.5 (molar ratio), then add glacial acetic acid dropwise (glacial acetic acid: methyl acrylate=5:1 (volume ratio)), During the dropping process, the temperature was slowly raised to 40-80° C. for the reaction, and the reaction process was monitored by TLC (trichloromethane:methanol, v / v=10:1-35:1) on a silica gel plate. After about 10-100 hours, the reaction was stopped, and excess methyl acrylate and glacial acetic acid were removed by rotary evaporation. The resulting residue was subjected to silica gel column chromatography (chloroform: acetone, v / v=10:1-30:1) to obtain a pale yellow oil, which was recrystallized from n-isopropyl ether to obtain a pure intermediate with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com