Ordered mesoporous carbon-zirconium dioxide composite and preparation method thereof

A zirconium dioxide and composite material technology, applied in the field of materials, can solve the problems of low ZrO2 content, uneven particle size, uneven particle distribution, etc., and achieve the effects of good characteristics, uniform pore size distribution and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 2

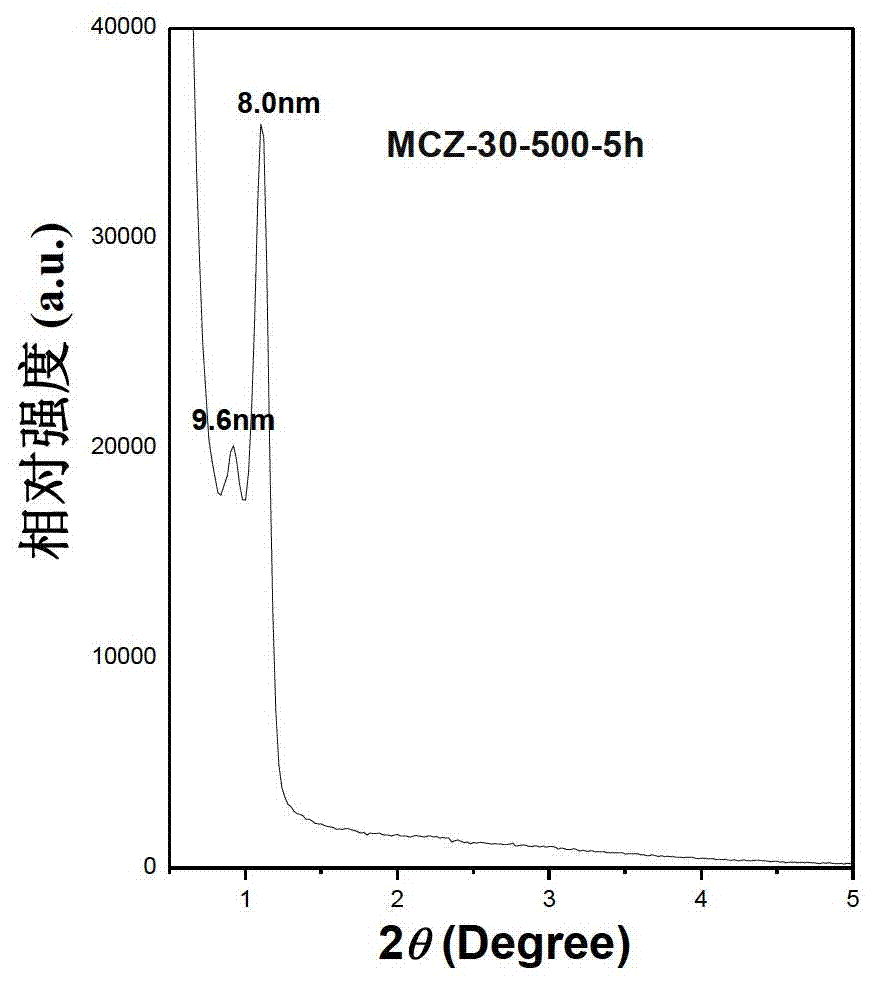

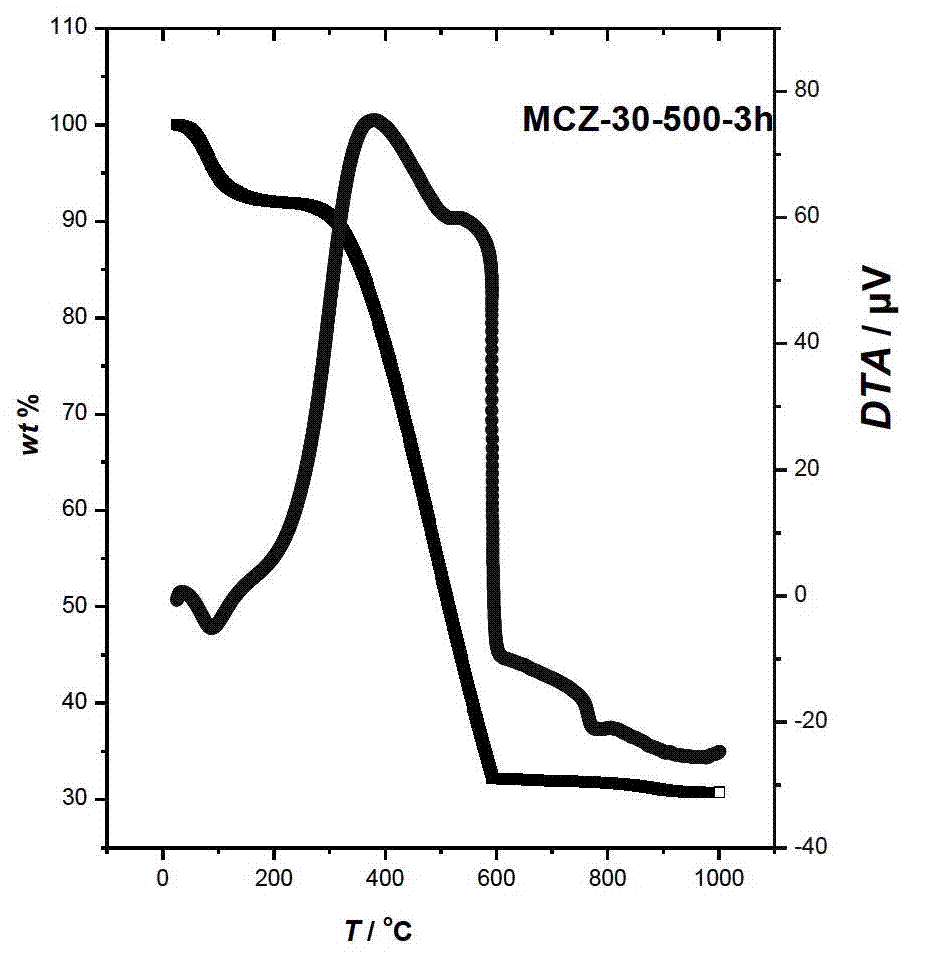

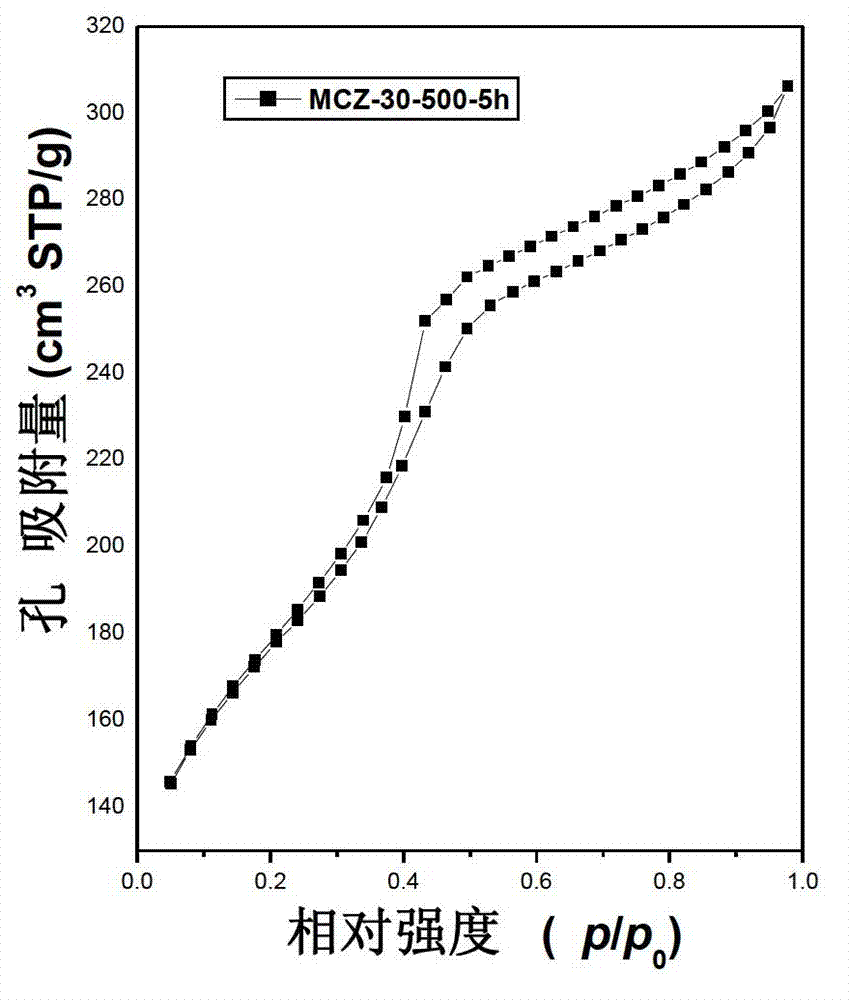

[0030] Example 1 Preparation of ordered mesoporous carbon-zirconia composite material with zirconia content of 30wt%.

[0031] Step 1: Pre-hydrolysis of zirconium tetrachloride: First, at 0°C, stir and mix 7.50ml of ethanol and 0.50ml of distilled water, cool to 0°C, add 0.643g of zirconium tetrachloride (2.75mmol) into the mixed solution, stir 2h. Zirconium tetrachloride was prehydrolyzed to form Stober's solution.

[0032] Step 2: At the same time as Step 1, dissolve 1.60 g of F127 in a mixed solution of 1.00 ml of distilled water and 8.00 g of ethanol at 40° C., and stir for 2 hours.

[0033] Step 3: Slowly transfer the Stober's solution dropwise to the solution in Step 2, and keep stirring at 40° C. for 0.5 h.

[0034] Step 4: Weigh 5.0 g of an ethanol solution of 20 wt % resole phenolic resin (molecular weight 1000) treated with anhydrous magnesium sulfate, add to the above solution, and continue stirring for 0.5 h.

[0035] Step 5: Apply the above solution evenly on t...

Embodiment 2 2

[0041] Example 2 Preparation of an ordered mesoporous carbon-zirconia composite material with a zirconia content of 50 wt%.

[0042] Step 1: Pre-hydrolysis of zirconium tetrachloride: First, at 0°C, 7.50ml of ethanol and 0.50ml of distilled water were stirred and mixed evenly, cooled to 0°C, 0.643g of zirconium tetrachloride was added to the mixed solution, and stirred for 2h. Zirconium tetrachloride was prehydrolyzed to form Stober's solution.

[0043] Step 2: At the same time as step 1, dissolve 1.00 g of F127 in a mixed solution of 1.00 ml of distilled water and 8.00 g of ethanol at 40° C., and stir for 2 hours.

[0044] Step 3: Slowly transfer the Stober's solution dropwise to the solution in Step 2, and keep stirring at 40° C. for 0.5 h.

[0045] Step 4: Weigh 3.0 g of an ethanol solution of 20 wt % resole phenolic resin (molecular weight 500) treated with anhydrous magnesium sulfate, add to the above solution, and continue stirring for 0.5 h.

[0046] Step 5: Apply the...

Embodiment 3 2

[0050] Example 3 Preparation of ordered mesoporous carbon-zirconia composite material with zirconia content of 70wt%.

[0051] Step 1: Prehydrolysis of zirconium tetrachloride: First, at 0°C, 7.50ml of ethanol and 0.50ml of distilled water were stirred and mixed evenly, cooled to 0°C, 0.643g of zirconium tetrachloride was added to the mixed solution, and stirred for 2h. Zirconium tetrachloride was prehydrolyzed to form Stober's solution.

[0052] Step 2: At the same time as step 1, dissolve 0.60 g of F127 in a mixed solution of 1.00 ml of distilled water and 8.00 g of ethanol at 40° C., and stir for 2 hours.

[0053] Step 3: Slowly transfer the Stober's solution dropwise to the solution in Step 2, and keep stirring at 40° C. for 0.5 h.

[0054] Step 4: Weigh 1.6g of an ethanol solution of 20wt% resole phenolic resin (molecular weight: 2000) treated with anhydrous magnesium sulfate, add to the above solution, and continue to stir for 0.5h.

[0055] Step 5: Apply the above sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com