Preparation method of lithium iron phosphate lithium ion battery for large-capacity vehicle

A lithium-ion battery and lithium iron phosphate technology, which is applied in the manufacture of electrolyte batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve problems such as water absorption, coating difficulties, and lithium iron phosphate processing difficulties, and achieve uniform temperature distribution and low cost. Low, safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

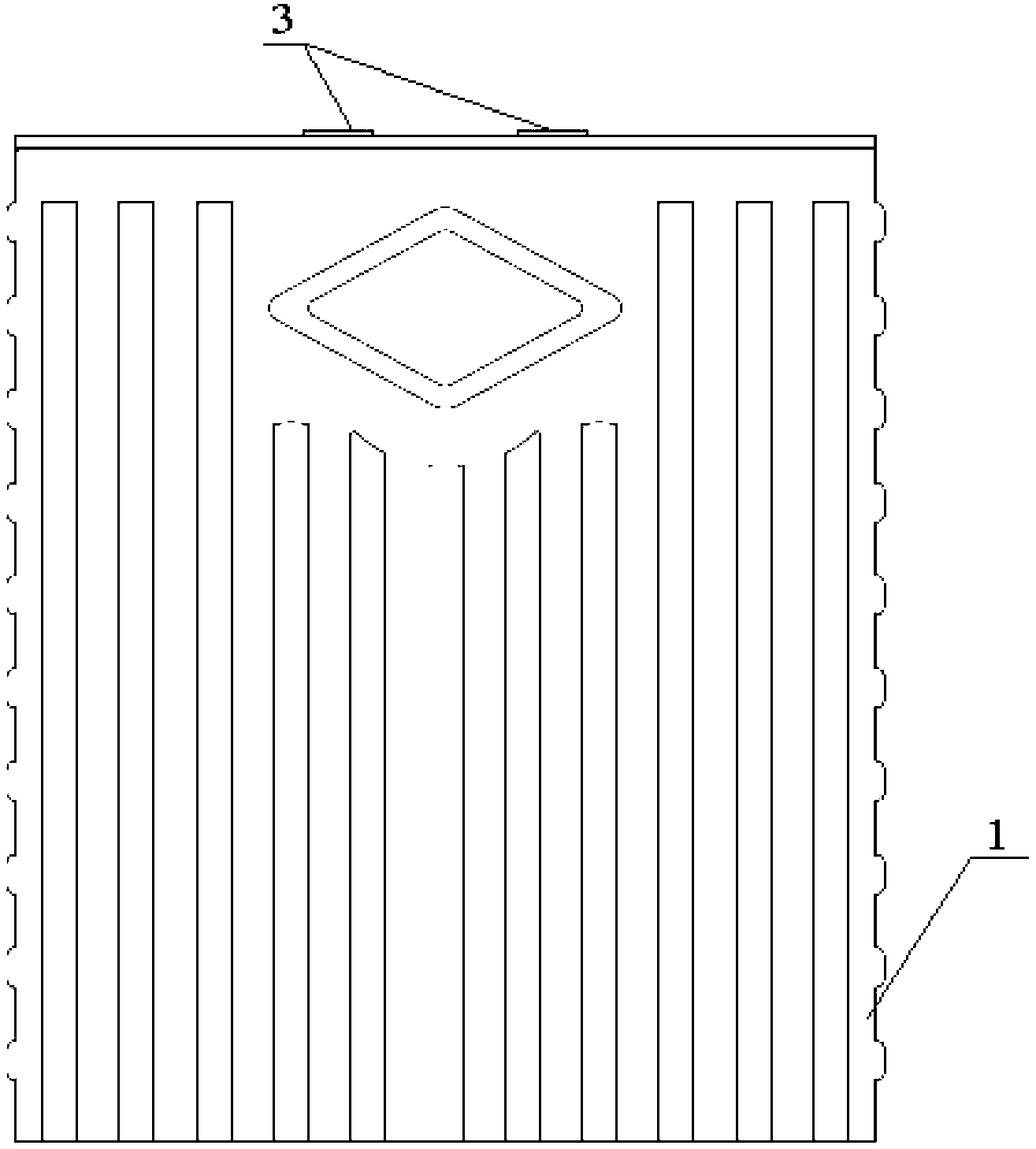

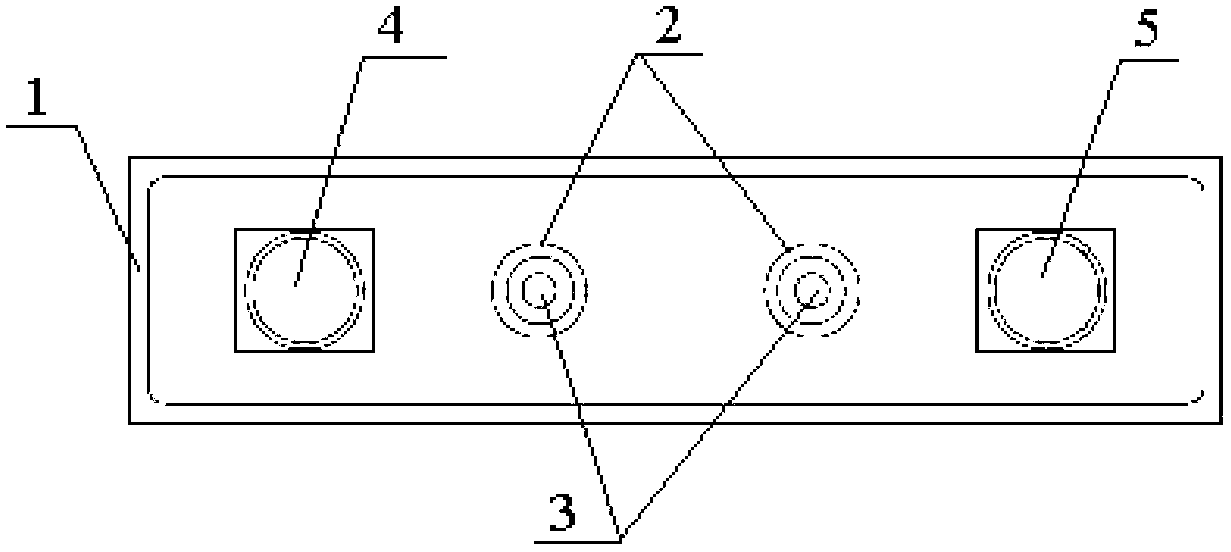

Image

Examples

Embodiment 1

[0046] (1) According to the weight percentage, put 86% conductive carbon powder, 0.5% conductive carbon black SP, 4% binder (SBR-CMC-LA132 system) and the rest of the solvent in the agitator, vacuumize fully Stir to make a slurry, and evenly coat the slurry on a 10 μm copper foil to obtain a battery negative electrode sheet;

[0047] The preparation process of the above slurry is specifically:

[0048] ① First bake the carbon powder, conductive carbon black SP and CMC in a vacuum oven;

[0049] ② Add CMC to the solvent, vacuumize and stir in the agitator at a speed of 2200 revolutions / min and 19 revolutions / min to obtain a uniform and transparent adhesive liquid system;

[0050] ③Add the LA132 emulsion to the above-mentioned bonding liquid system, and vacuumize and stir at the speed of rotation 1400 rpm and revolution 14 rpm to obtain a uniform and stable system;

[0051] ④Put conductive carbon black SP and carbon powder into the agitator successively, vacuumize and stir at ...

Embodiment 2

[0061] (1) According to weight percentage, put 93% conductive carbon powder, 2% conductive carbon black SP, 4% binder (SBR-CMC-LA132 system) and the rest of the solvent in the stirrer, vacuum fully Stir to make a slurry, and evenly coat the slurry on a 20 μm copper foil to obtain a battery negative electrode sheet;

[0062] The preparation process of the above slurry is specifically:

[0063] ① First bake the carbon powder, conductive carbon black SP and CMC in a vacuum oven;

[0064] ② Add CMC to the solvent, vacuumize and stir in the agitator at a speed of 2400 revolutions / min and 21 revolutions / min to obtain a uniform and transparent adhesive liquid system;

[0065] ③ Add the LA132 emulsion to the above-mentioned adhesive liquid system, vacuumize and stir at the speed of rotation 1600 rpm and revolution 16 rpm to obtain a uniform and stable system;

[0066] ④Put conductive carbon black SP and carbon powder into the agitator successively, vacuumize and stir at the speed of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com