Method for preparing high-capacity lithium iron phosphate lithium ion battery for automobile

A lithium-ion battery and lithium iron phosphate technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, non-aqueous electrolyte batteries, etc., can solve the problems of coating difficulty, difficulty in processing lithium iron phosphate, water absorption, etc., and achieve low cost and ensure Safe, even temperature distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) According to weight percentage, put 86% conductive carbon powder, 0.5% conductive carbon black SP, 4% binder (SBR-CMC-LA132 system) and the rest of the solvent in the stirrer, vacuum 1700rpm Fully stir to make a slurry, and evenly coat the slurry on a 10 μm copper foil to obtain a negative electrode sheet of the battery;

[0030] (2) After drying, rolling, slitting, die-cutting, and stacking the positive pole pieces (50 positive pole pieces and 51 negative pole pieces), the above-mentioned negative pole pieces are made into batteries;

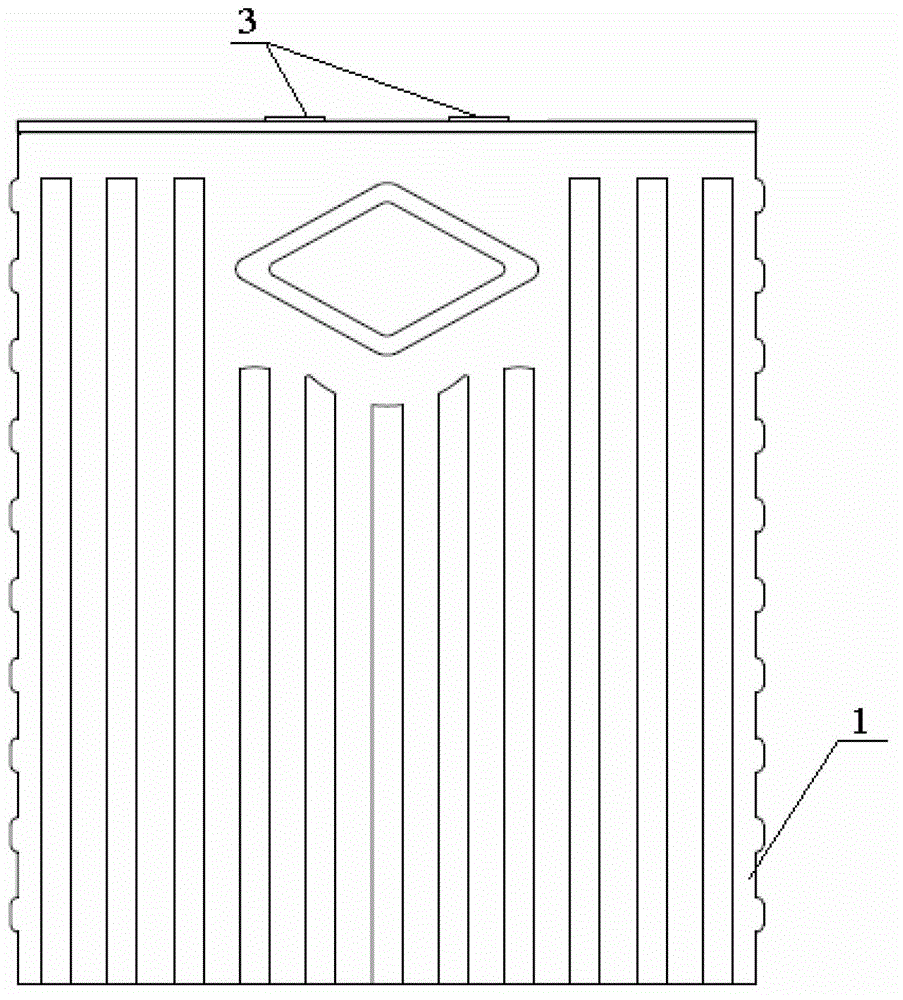

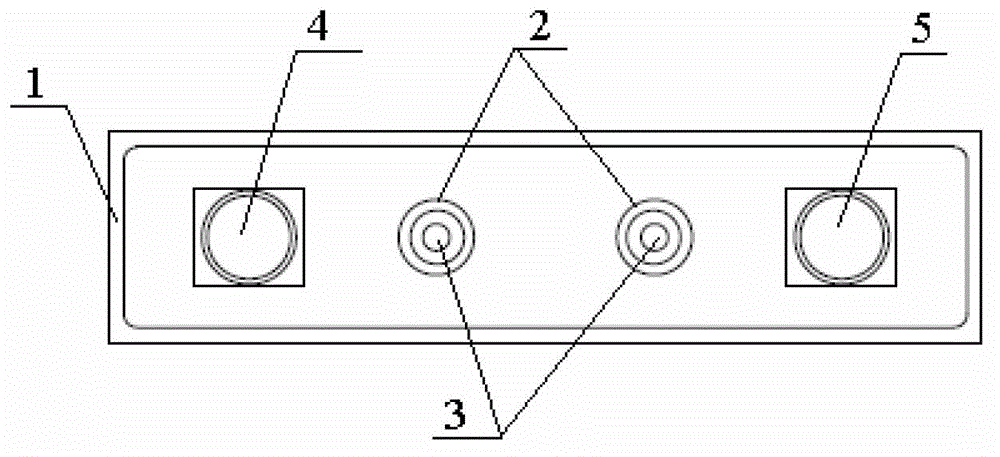

[0031] (3) Put the above-mentioned batteries into a plastic case after drying, package, and leak detection; wherein, the top of the plastic case is provided with a liquid injection hole, and a spring micro-opening safety valve is installed on the liquid injection hole;

[0032] (4) Vacuumize the above-mentioned packaged and dried battery, inject liquid, and put it aside;

[0033] (5) Precharge, high temperature (temperature: 45°C, a...

Embodiment 2

[0035] (1) According to weight percentage, put 94% conductive carbon powder, 2% conductive carbon black SP, 4% binder (SBR-CMC-LA132 system) and the rest of the solvent in the stirrer, vacuum 2100rpm Fully stir to make a slurry, and evenly coat the slurry on a 20 μm copper foil to obtain a negative electrode sheet of the battery;

[0036] (2) After drying, rolling, slitting, die-cutting, and stacking the positive pole pieces (80 positive pole pieces and 81 negative pole pieces), the above-mentioned negative pole pieces are made into batteries;

[0037] (3) Put the above-mentioned batteries into a plastic case after drying, package, and leak detection; wherein, the top of the plastic case is provided with a liquid injection hole, and a spring micro-opening safety valve is installed on the liquid injection hole;

[0038] (4) Vacuumize the above-mentioned packaged and dried battery, inject liquid, and put it aside;

[0039] (5) Precharge, high temperature (temperature: 45°C, agi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com