Electronically controlled single-loop water-plugging overburden strata fracture detection method and probing machine

A single-circuit, electronically controlled technology, applied in the direction of testing machinery, earthwork drilling and mining, etc., can solve problems such as high-pressure air pipe breakage, inability to effectively block holes, and inaccurate measurement, so as to prevent bursting accidents, facilitate popularization and use, and The effect of simplifying the operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The detection steps of the present invention are as follows:

[0023] Step 1: Prepare an electronically controlled single-circuit water blocking rock fissure detector

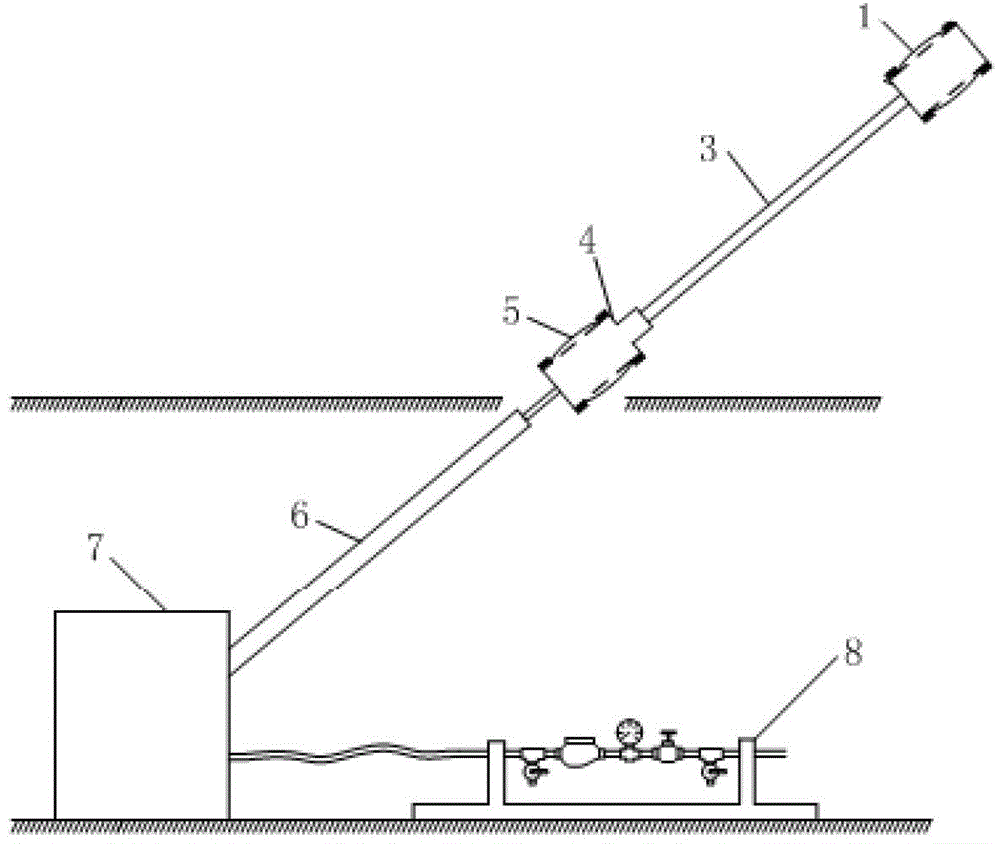

[0024] The detector structure is as figure 1 As shown, it is that an upper sealing capsule 1 and a lower sealing capsule 5 are respectively installed at both ends of the connecting pipe 3; a water flow regulating device 4 is arranged in the lower sealing capsule 5;

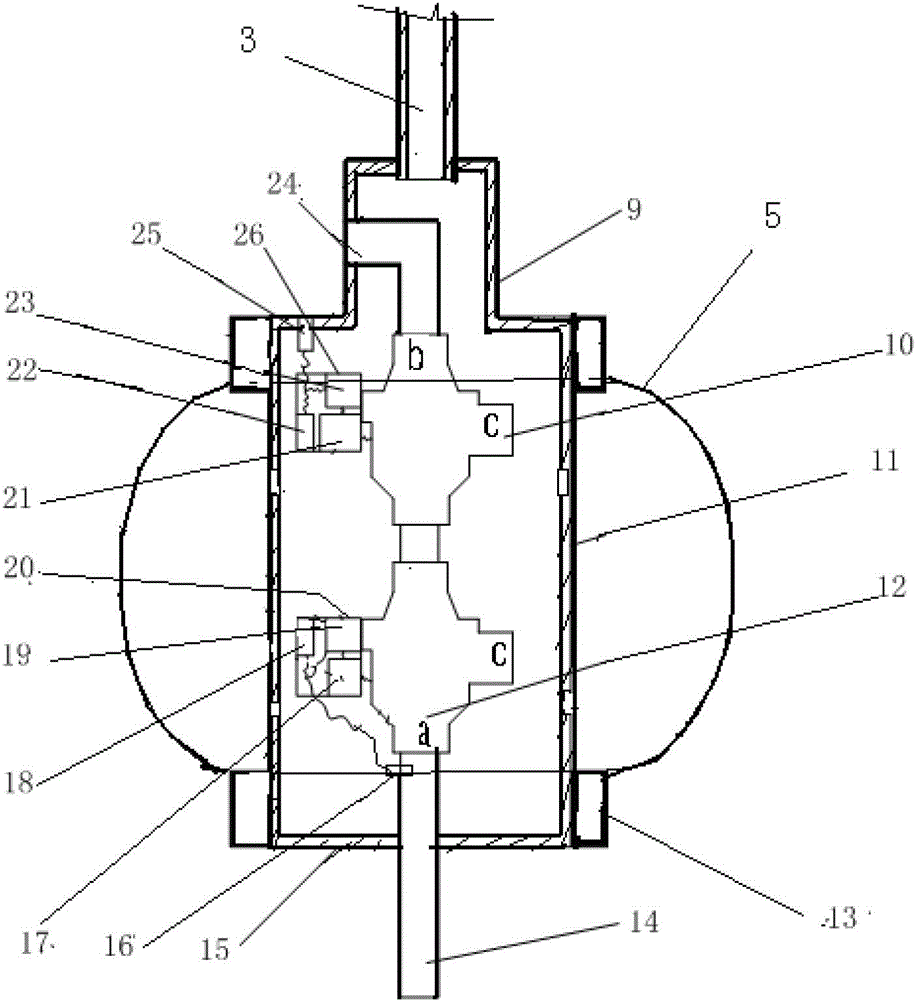

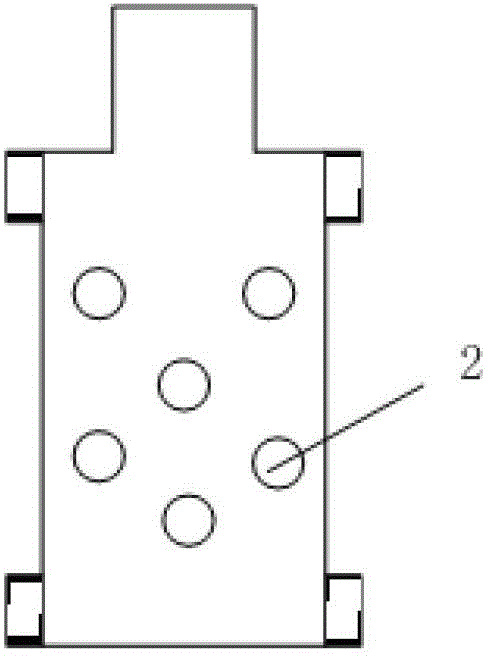

[0025] Such as figure 2 As shown, the above-mentioned water flow regulating device includes a casing 11, the casing 11 is provided with a top cover 9 and a bottom cover 15, and the top cover 9 is connected to the connecting pipe 3; Lead electromagnetic valve 10 and 12; Shell 11 walls are provided with some through holes 2 leading to capsule (as image 3 shown); the two ends of the outer wall of the shell 11 are respectively provided with raised rings 13 for fixing and protecting the capsule; the upper and lower two two-position three-way...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com