Micro-hole strengthening method combining cone pressure and laser impact

A laser shock strengthening and laser shock technology, used in the field of surface strengthening of parts, can solve the problems of uneven stress distribution in the thickness direction, difficult to remove the mandrel, unable to guarantee the hole wall, etc., to improve the fatigue life and stress corrosion resistance performance, use Increases life and strength, reduces thermal damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

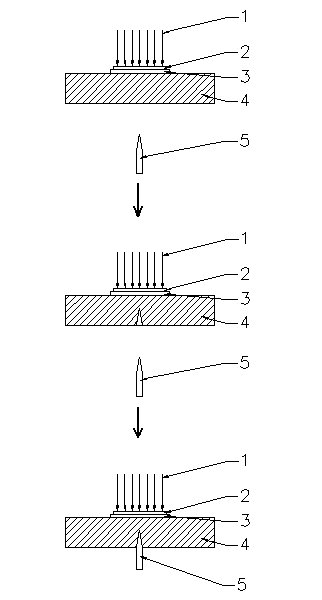

[0034] Example 2 as figure 1 As shown in (c), this example takes 304 stainless steel sheet material as an example, combining an implementation mode in the process figure 1(c) To elaborate, the thickness of the plate in the example is 6mm. After the test piece is pretreated to ensure the cleanliness and smoothness of the surface of the part, aluminum foil is pasted on the small hole of the test piece to be processed as an energy absorption layer (3) , and then use normal temperature flowing water as the constraining layer (2) outside the aluminum foil to protect the sheet / workpiece (4) from heat during the laser shock process to reduce the thermal damage of the laser to the sheet / workpiece (4); then 304 The stainless steel specimen is pressed in. In this example, a diamond sintered conical indenter is used. The taper of the indenter is 1:2. The maximum diameter of the conical indenter section is 2mm, and the indentation depth is 4mm. After completion, keep the extrusion state ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com